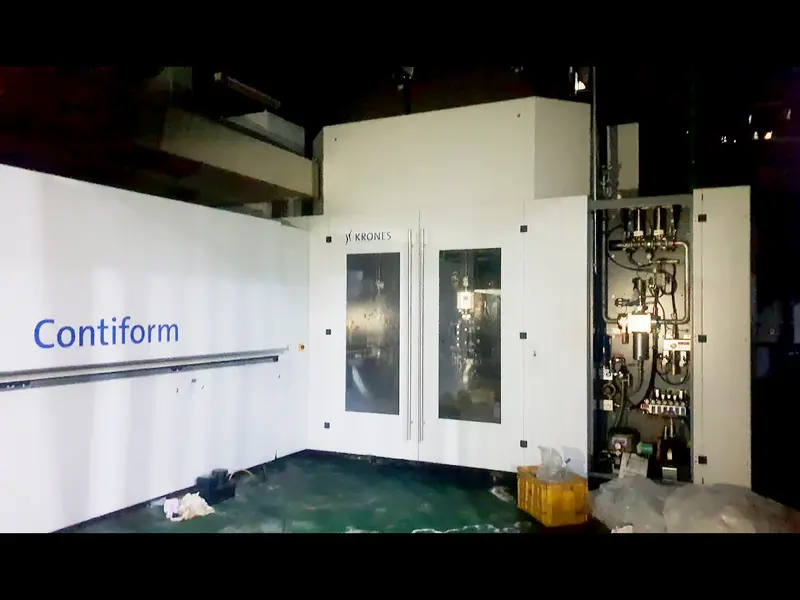

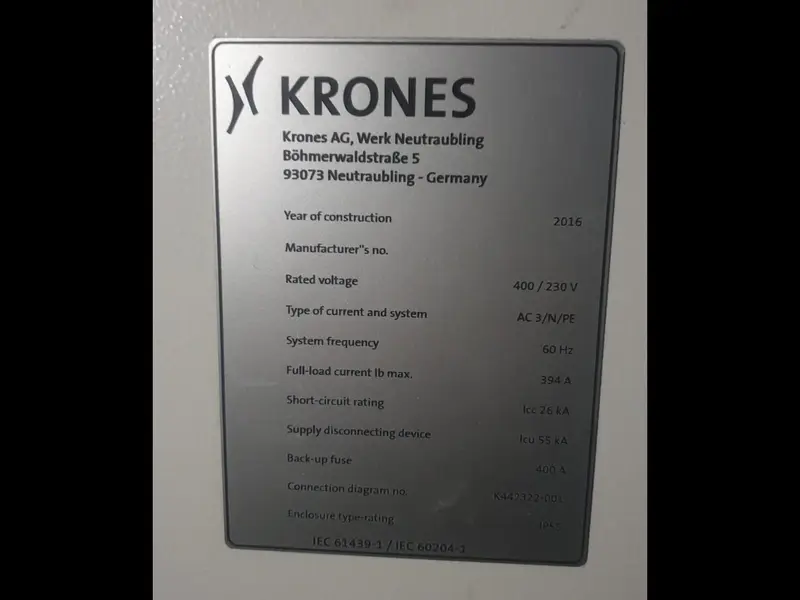

Used Blow Molding Machine KRONES Contiform C312 PRO Year 2016

Introducing the Blow Molding Machine KRONES Contiform C312

The KRONES Contiform C312 PRO blow molding machine, manufactured in 2016, represents the pinnacle in the bottling industry. Crafted by the renowned German company Krones, this model delivers reliable, high-quality performance to meet the most demanding sector requirements.

Performance and Capacity of the Machinery

Featuring a 12-cavity mold, the Blow Molding Machine KRONES Contiform C312 operates at a maximum speed of 27,000 bottles per hour (bph). This remarkable production speed ensures a steady, efficient flow, thereby optimizing processing times and maximizing productivity.

Versatility and Adaptability of the Blow Molding Machine KRONES Contiform C312

Moreover, its ability to adapt to various product types, including square and round shapes, makes the Contiform C312 PRO highly versatile. This feature facilitates a wide range of applications in the bottling industry, offering operational flexibility and production diversification possibilities.

Structural Solidity and Durability

Weighing 25.0 tons, the machinery is built to withstand the continuous demands of the production environment. Its solid, reliable structure ensures long-lasting performance, consequently minimizing downtime and ensuring uninterrupted production.

Efficiency in Material Handling

Additionally, equipped with a tilter with a maximum capacity of 2.0 tons, the Blow Molding Machine KRONES Contiform C312 enables high efficiency in material movement and handling. This feature optimizes logistical processes within the company, thereby reducing loading and unloading times and enhancing overall operational efficiency.

Advanced Technology and Optimal Performance

Furthermore, the 150 kW blowing system ensures excellent material distribution, thereby guaranteeing the formation of perfectly shaped bottles free from defects. Additionally, the machinery is fitted with a 5 kW air conveyor and offers an air flow rate of 14㎥/h at 11°C and 1,100㎥/h, ensuring a constant, reliable flow during the production process.

Concluding Remarks on the KRONES Contiform C312 PRO

In conclusion, the Blow Molding Machine KRONES Contiform C312 stands out as the ideal choice for those seeking a high-quality used blow molding machine. With its robust construction, reliable performance, and advanced technology, this model offers an efficient and cost-effective solution for the most demanding bottling needs.