Description

Used Blow Molding Machine SMI EBS 10 year 2019

Introduction to the Blow Molding machine SMI EBS 10

Initially, the industrial bottling sector demands unparalleled precision and operational efficiency. Consequently, this Blow Molding Machine from 2019 perfectly embodies these crucial characteristics. This machine, ingeniously integrating advanced engineering, is specifically designed for the manufacturing of PET containers, showcasing its pivotal role in the industry.

Technological Capacity

Produced by SMI, the introduction of the EBS 10 ERGON model in 2019 stands as a testament to significant technological advancement. Boasting an impressive production capacity of 17,000 BPH (bottles per hour), this capacity is essential for meeting high-volume production demands. Additionally, it supports various container formats, including 0.20 L, 0.33 L, and 0.6 L, thereby significantly enhancing its utility across diverse bottling operations.

Operational Configuration

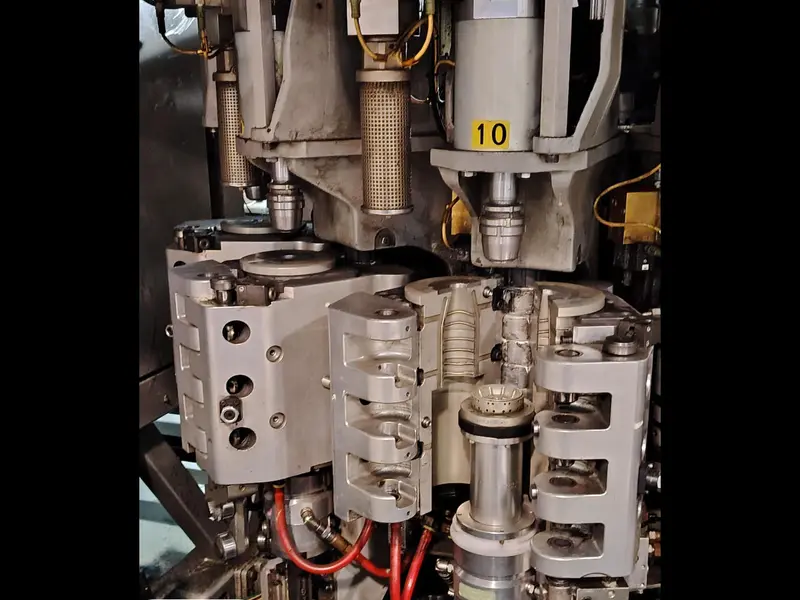

Moreover, the machine is equipped with 10 cavities, optimizing both production efficiency and consistency. Its extensive automatic preform feeding system, comprising loaders, tippers, and unscramblers, is meticulously designed to minimize downtime and maximize output. Furthermore, an integrated compressor and chiller ensure stable operational conditions, essential for continuous production processes. Also, the air recovery system plays a pivotal role in reducing energy consumption, aligning with current sustainability objectives.

Safety and Maintenance

Focusing on safety, the machine’s design incorporates several protective devices, crucial for preventing operational accidents. Presently, the machine remains in production, having accumulated 24,000 hours of operation, which demonstrates its robustness and reliability. Additionally, the provision of technical documentation facilitates routine maintenance and performance optimization, ensuring the machine’s longevity and sustained operational efficiency.

Conclusion of the Blow Molding machine SMI EBS 10

In conclusion, the adoption of the Used SMI EBS 10 Blow Molding Machine from 2019 significantly enhances the value within the bottling industry. Its advanced engineering technology, coupled with comprehensive safety features, not only meets but also anticipates the complex needs of production environments. By maintaining high product quality standards with unmatched precision and reliability, this machine stands as a critical addition to any bottling operation aiming to boost efficiency and productivity.