Description

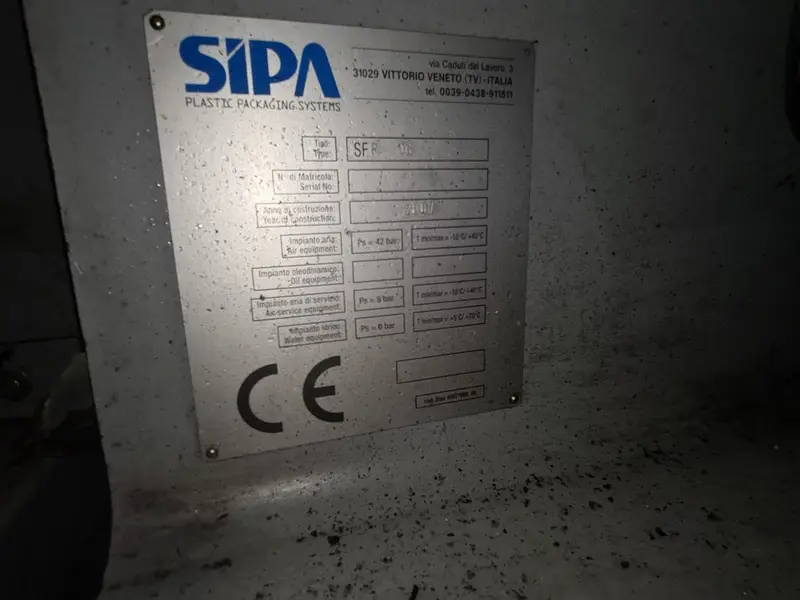

Used Blow Molding Machine Sipa SFR 16

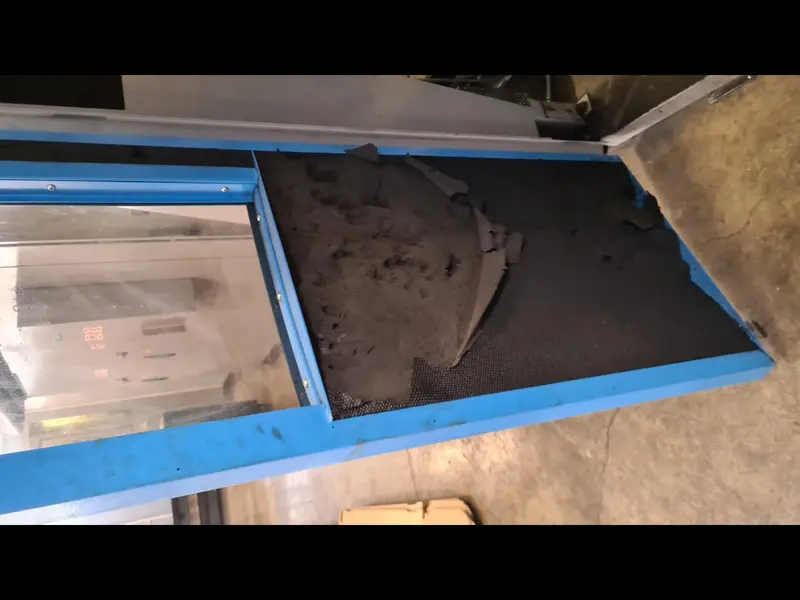

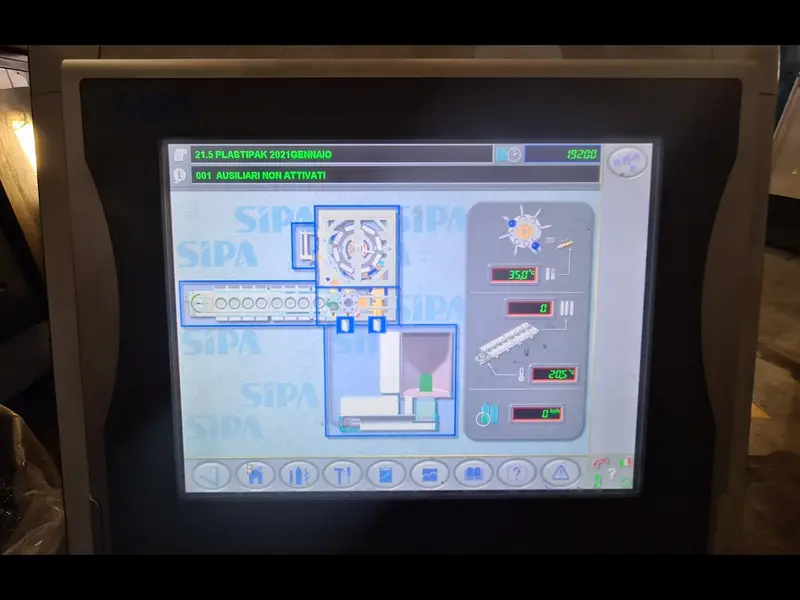

Assessment of Heating System and Preform Feeding

Firstly, a comprehensive evaluation of the entire oven system is imperative, encompassing turning-over ramps and tension wheel guides, to ensure an efficient and seamless bottle forming process.

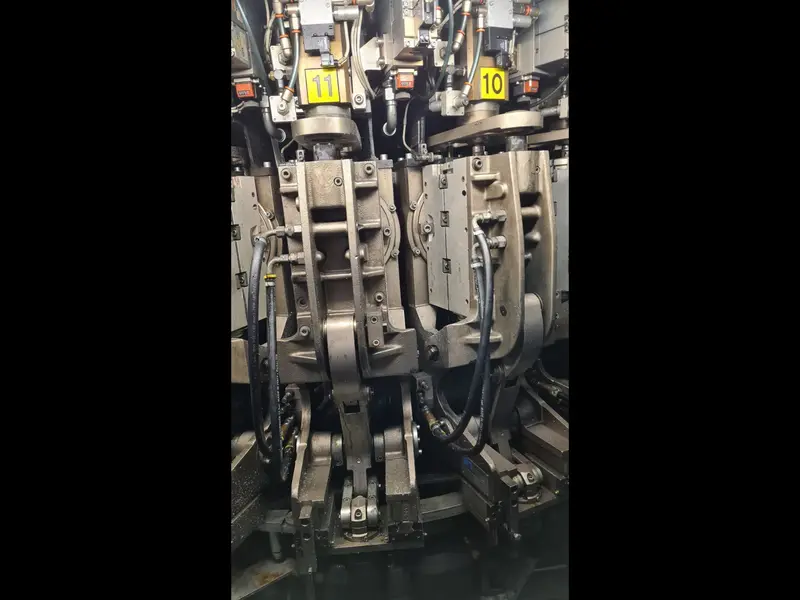

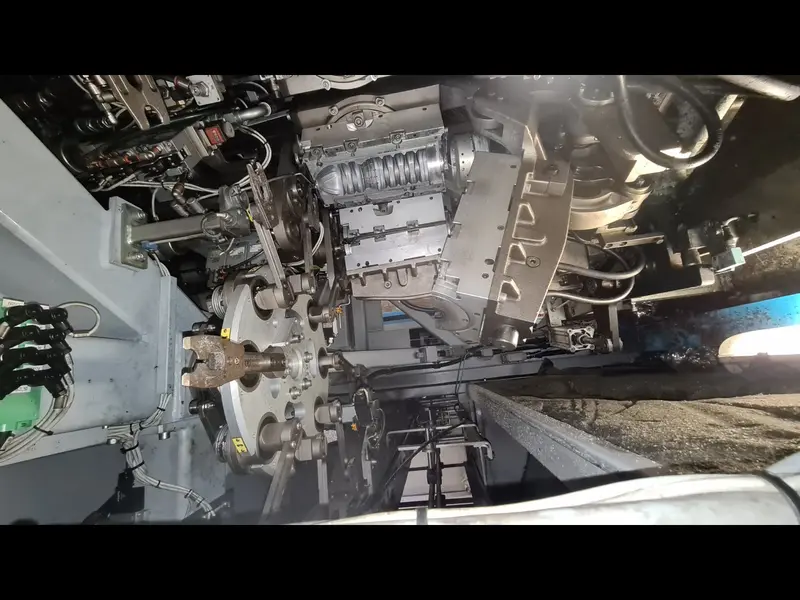

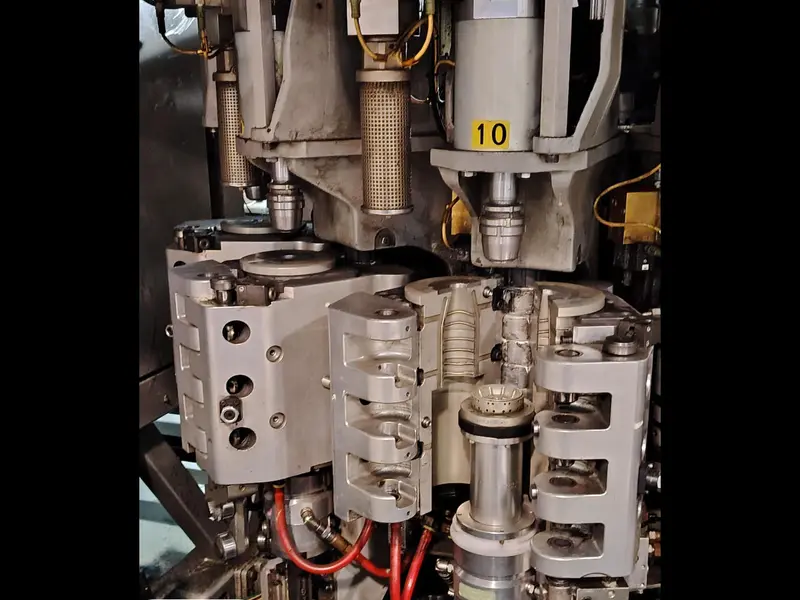

Evaluation of Transfer Arms and Cams of the Sipa blower

An indispensable aspect pertains to the scrutiny of transfer arms and cams. These components play a pivotal role in maintaining a continuous and uninterrupted production flow. Furthermore, meticulous inspection of their functionality is essential to uphold the quality and precision of the blow molding process.

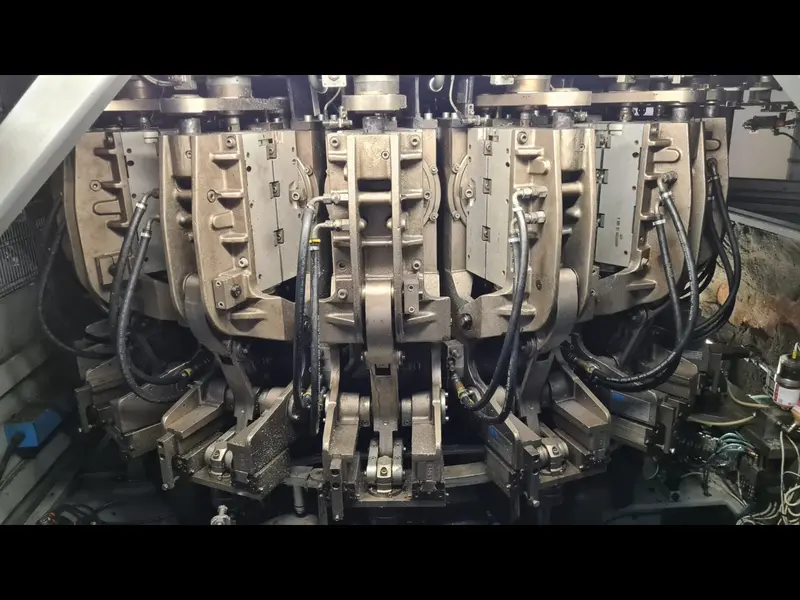

Condition of Molds and Stretching Mechanism

Equal emphasis is placed on assessing the condition of molds and the stretching mechanism. The accuracy and integrity of the molds are pivotal in producing flawless, high-quality bottles. Consequently, conducting a thorough assessment of these components is essential to ensure optimal machinery operation.

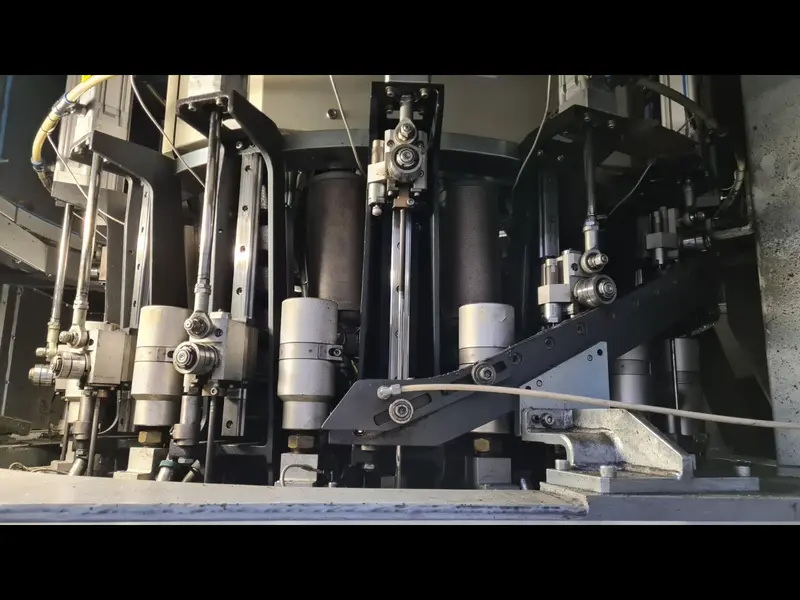

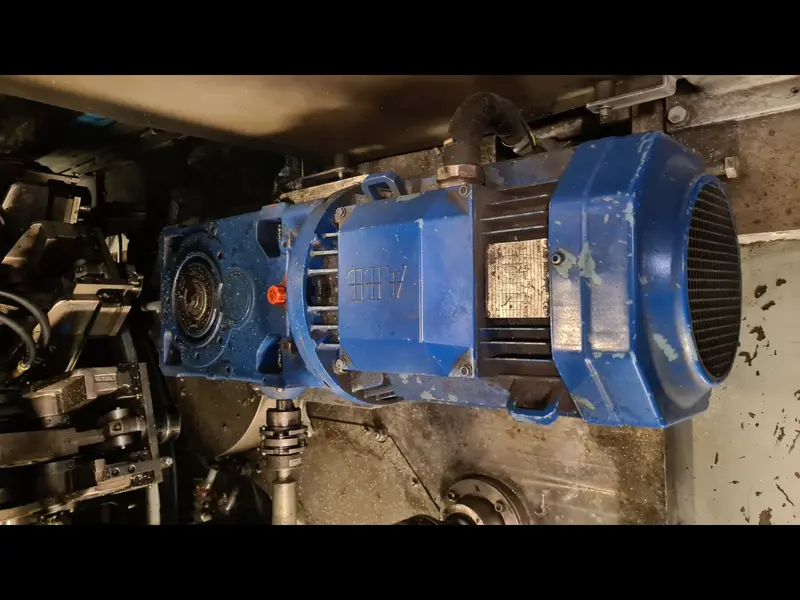

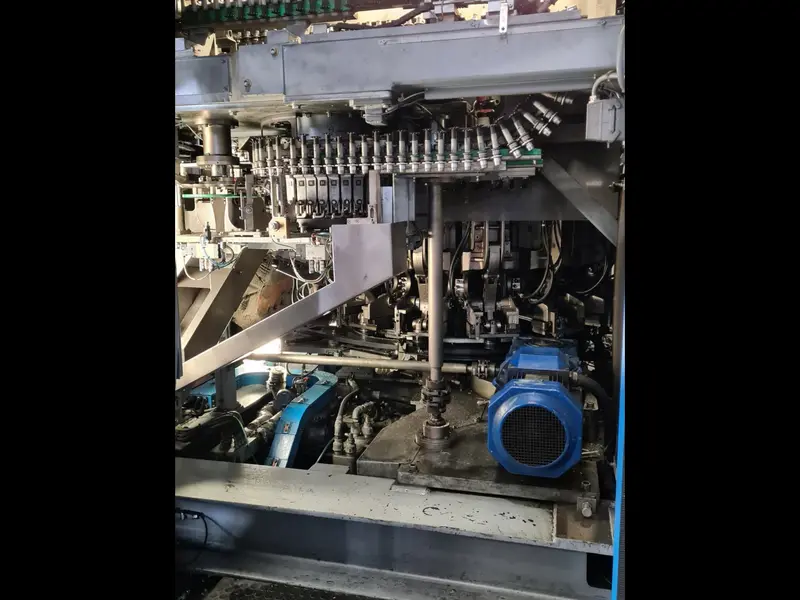

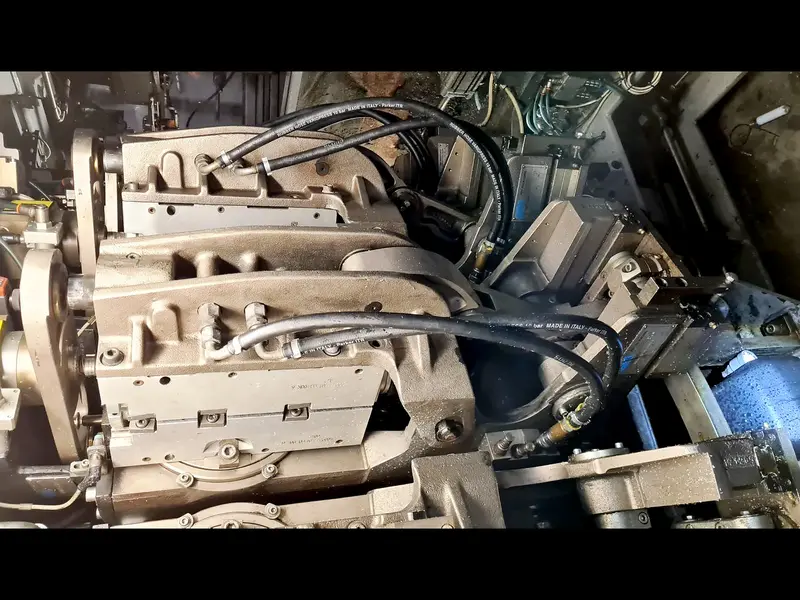

Examination of Water and Air Circuits in the Sipa blower

Subsequently, the integrity of water and air circuits, integral components for preform cooling and pressure control during the blow molding process, is scrutinized. Ensuring proper circulation of water and air is crucial for maintaining stable working conditions and guaranteeing the quality of the final product.

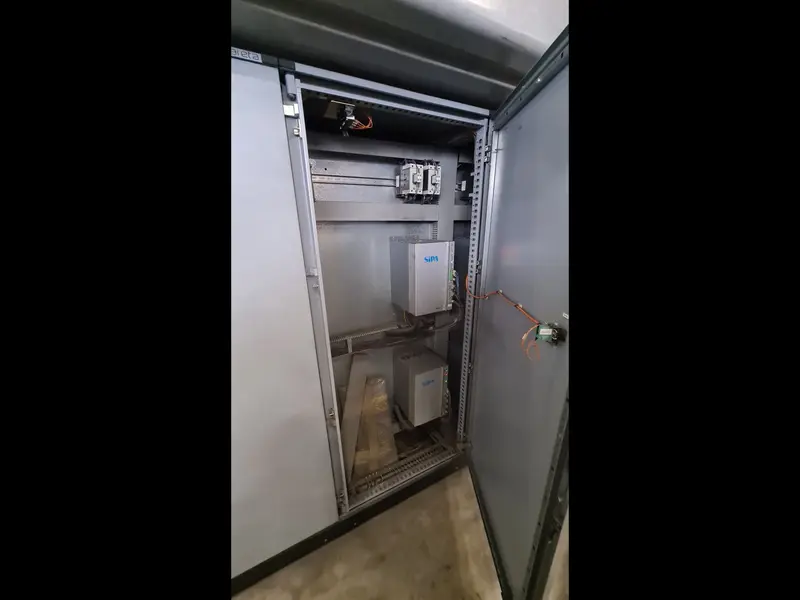

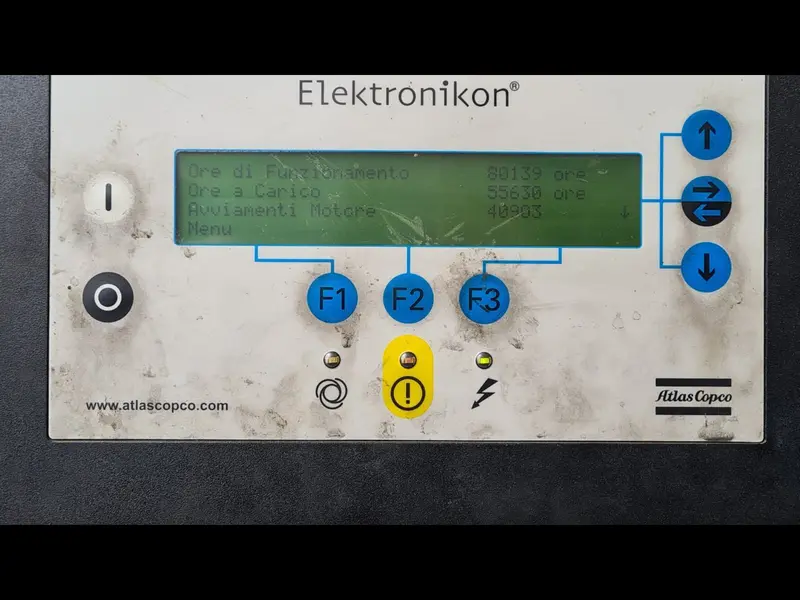

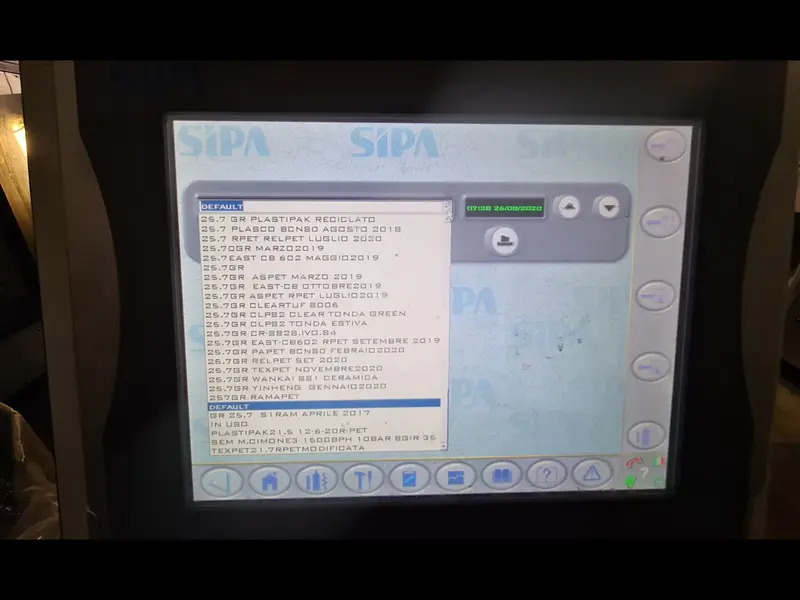

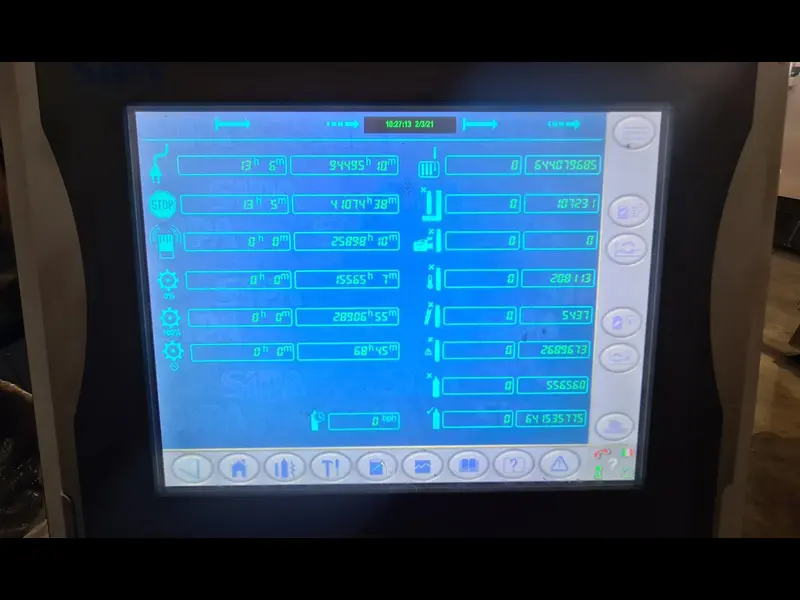

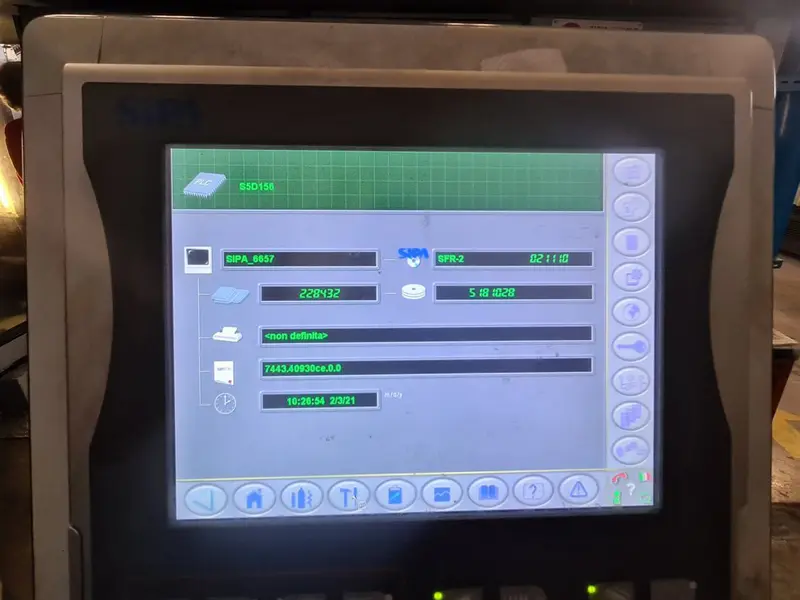

Technical Specifications and Additional Details

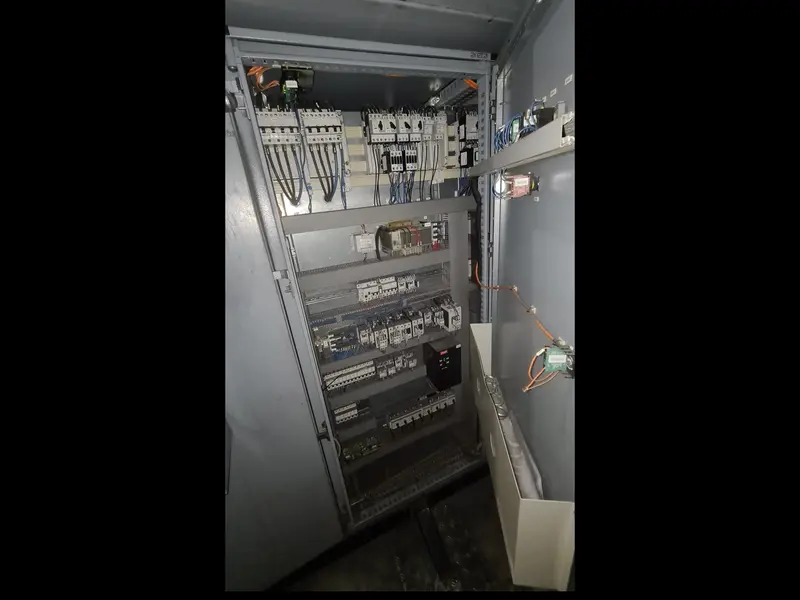

In terms of technical specifications, pertinent details are provided regarding available SKUs and the weight of PET preforms per SKU. Specifically, for 0.5 L, the weight is 14 g, for 1.0 L, it is 26 g, for 1.5 L, it remains at 26 g, and for 2.0 L, it ranges from 29-31 g. It is important to note that the existing molds of the Sipa blower will not be supplied with the machine; replacement is at the discretion of the buyer. Additionally, the preform neck is specified as Corvaglia 28. Further technical details include the identification of the electrical cabinet and Command panel PLC of the Sipa blower as Siemens S7, along with the total number of cavities, which amounts to 16.

Main observations on blowing machine

Oven and the Preform in-feed

Condition of the Following:

Oven, Turning-over ramps _ guiding and tension wheel

Heating modules, Oven ventilation and Cooling shields

Transfer arms and Cams

Moulds and Stretching mechanism

Water and Air Circuits

All these are in great conditions

Number of SKUs and PET preform weight per SKU

0,5 L: 14 g

1,0 L: 26 g

1,5 L: 26 g

2,0 L: 29-31 g

The existing molds will be supplied along with the machine.

Current bottle drawings can be supplied as well.

You will replace them if you want something different.

Preform Neck

Alaska 3-start

Electrical cabinet and Command panel

PLC: Siemens S7, great overall condition