Description

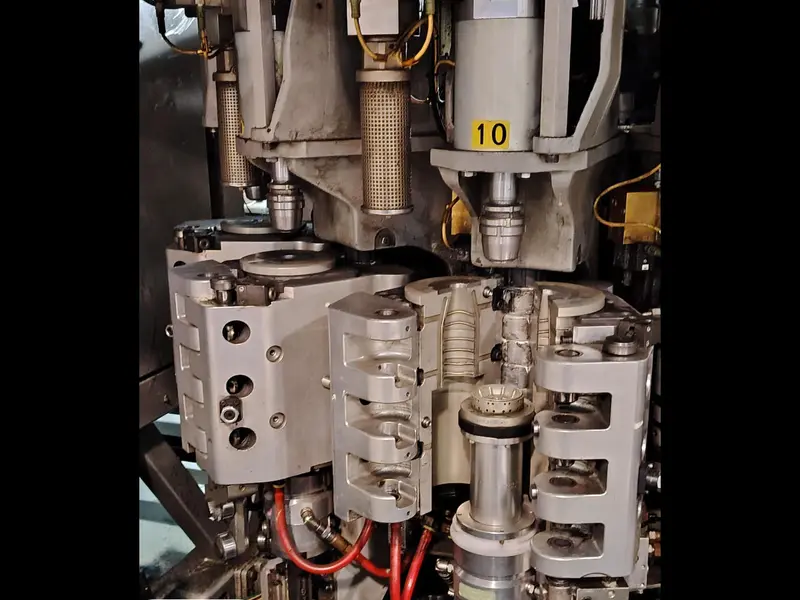

Used blow moulding machine Sidel SBO 8 series 2+ up to 12000 bph

Introduction of the blow moulding machine Sidel SBO 8

In the bottling field, the choice of suitable machinery is crucial. The used Sidel SBO 8 blow molding machine series 2+ stands out for its production capacity and reliability. Designed in 2004, this 2+ series represents a cost-effective option for companies looking for efficiency and quality in the bottling sector.

Technical details

The Sidel SBO 8, series 2+, is a bottle blowing machine that has accumulated 19857 working hours. This data reflects the experience and resistance of the machinery over the years. It is important to note that, the machine is sold without molds. This offers considerable flexibility in terms of customization and adaptability to specific production needs.

Maintenance and Reliability of the blow moulding machine Sidel SBO 8

The last maintenance intervention was carried out in February 2023. This testifies the constant commitment to maintaining the efficiency of the machinery. Regular maintenance is a fundamental aspect to guarantee maximum performance and reliability, which is a crucial aspects in a competitive sector such as bottling.

Production capacity

The strong point of the Sidel SBO 8 blow molding machine is its high production capacity, which reaches up to 12000 bph (bottles per hour). This makes the machinery extremely suitable for medium-large scale operations, where speed of production is an essential requirement.

Conclusion

The used Sidel SBO 8 blow molding machine, with its considerable operational experience and constant maintenance, represents an excellent solution for companies in the bottling sector. With its high production capacity and proven reliability, this machinery is a strategic choice for those aiming to optimize production without compromising on quality.