Description

Used Blow Molding Machine UROLA MSC6 HDPE Year 2019

Introduction:

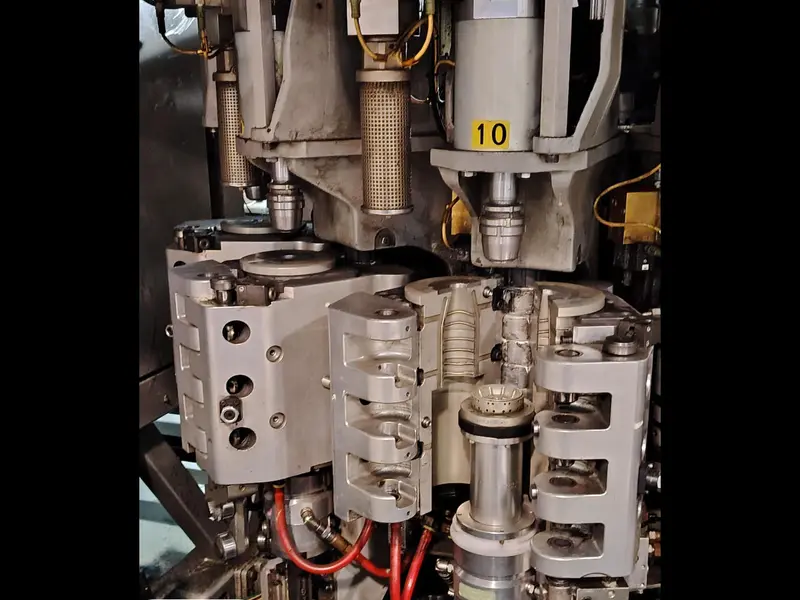

The UROLA MSC6 HDPE blow molding machine, manufactured in 2019, stands as a pinnacle in HDPE bottle production technology. Equipped with six moulds, this rotary blow molder sets a new standard in efficiency and performance.

Technical Specifications:

The UROLA MSC6 HDPE utilizes a rotary blowing unit featuring six cavities, capable of achieving a maximum output of 1600 bottles per hour. Furthermore, the machine boasts a maximum mould opening of 240mm and a mould clamping force of 9,000 kg, ensuring precision and stability in the production process.

Blower HDPE:

Crafted specifically for High-Density Polyethylene (HDPE) bottle production, the UROLA MSC6 HDPE guarantees superior quality and durability. Its advanced design and engineering cater to the demanding requirements of the packaging industry, making it an ideal choice for manufacturers seeking reliability and efficiency.

Brand and Model

UROLA, a renowned name in the realm of blow molding machinery, presents the MSC6 model, setting a benchmark in the industry. With its innovative features and robust construction, this machine exemplifies the brand’s commitment to excellence and customer satisfaction.

Year 2019:

Manufactured in 2019, the UROLA MSC6 HDPE embodies the latest advancements in blow molding technology. Its production in the recent year ensures compliance with modern standards and regulations, offering users peace of mind regarding performance and reliability.

Format and Capacity:

The UROLA MSC6 HDPE caters to diverse packaging needs. With a maximum capacity of 10,000 cc, a diameter of 200mm, and a height of 370mm, it accommodates various bottle sizes, enhancing versatility and flexibility in production.

Rotary Blowing Unit:

The rotary blowing unit of the UROLA MSC6 HDPE features six cavities, optimizing production efficiency while maintaining precision and consistency. Additionally, with a maximum output of 1600 bottles per hour, it ensures high productivity without compromising on quality.