Complete Bottling Line

Ref: LC396| Machine type | Manufacturer | Model | Year | Notes | |||||

|---|---|---|---|---|---|---|---|---|---|

| Machine type | Heat Exchanger | Manufacturer | Tetra Pak® | Model | Contherm | Year | 2015 | Notes | sterilization |

| Machine type | Fill and packaging | Manufacturer | FL TÈCNICS | Model | FL 2.2 | Year | 2015 | Notes | |

| Machine type | Fill Type | Manufacturer | Varpe | Model | Year | 2015 | Notes | Product weight control | |

| Machine type | Inspector | Manufacturer | Varpe | Model | Year | 2015 | Notes | RX control | |

| Machine type | Pasteurizer | Manufacturer | Sarp | Model | Year | 2015 | Notes | spiral type air | |

| Machine type | Case Erector | Manufacturer | Tavil | Model | Year | 2015 | Notes | ||

| Machine type | Case Packer | Manufacturer | Tavil | Model | Year | 2015 | Notes | pick and place grippers | |

| Machine type | Case Sealer | Manufacturer | Tavil | Model | Year | 2015 | Notes | Label and clousure | |

| Machine type | Palletizer | Manufacturer | Tavil | Model | Year | 2015 | Notes | Robot |

| Machine type | Manufacturer | Model | Year | Notes | |||||

|---|---|---|---|---|---|---|---|---|---|

| Machine type | Heat Exchanger | Manufacturer | Tetra Pak® | Model | Contherm | Year | 2015 | Notes | sterilization |

| Machine type | Fill and packaging | Manufacturer | FL TÈCNICS | Model | FL 2.2 | Year | 2015 | Notes | |

| Machine type | Fill Type | Manufacturer | Varpe | Model | Year | 2015 | Notes | Product weight control | |

| Machine type | Inspector | Manufacturer | Varpe | Model | Year | 2015 | Notes | RX control | |

| Machine type | Pasteurizer | Manufacturer | Sarp | Model | Year | 2015 | Notes | spiral type air | |

| Machine type | Case Erector | Manufacturer | Tavil | Model | Year | 2015 | Notes | ||

| Machine type | Case Packer | Manufacturer | Tavil | Model | Year | 2015 | Notes | pick and place grippers | |

| Machine type | Case Sealer | Manufacturer | Tavil | Model | Year | 2015 | Notes | Label and clousure | |

| Machine type | Palletizer | Manufacturer | Tavil | Model | Year | 2015 | Notes | Robot |

Related machines

Interested in this machine?

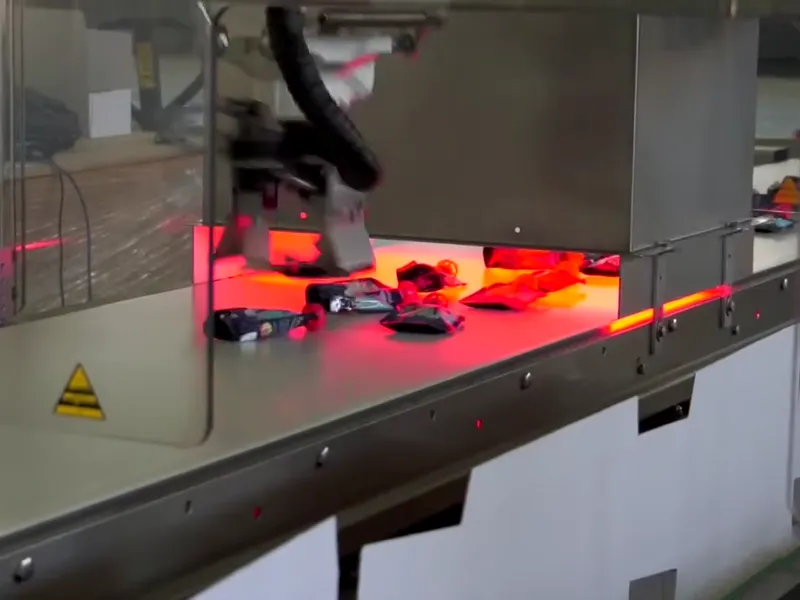

In a highly competitive and ever-evolving sector such as bottling and packaging, having high-quality equipment is crucial to ensuring efficiency and precision. One of the bottling lines that has proven to offer these qualities is the complete Doypack pouches line with a capacity of 600 kg/h. In addition, this machine could be described as approximately brand new as it has been used for only 1.000 hours to produce 5 million pouches.

With an operating speed of 600 Kg/h, this line is optimized for pouch containers and has a format capacity of 100g.

This makes it ideal for a wide range of products, including dairy products, juices, ready-to-drink, creams and sauces. One of its distinctive features is the weight-based filling type, thus ensuring that each bag contains the exact amount of product.

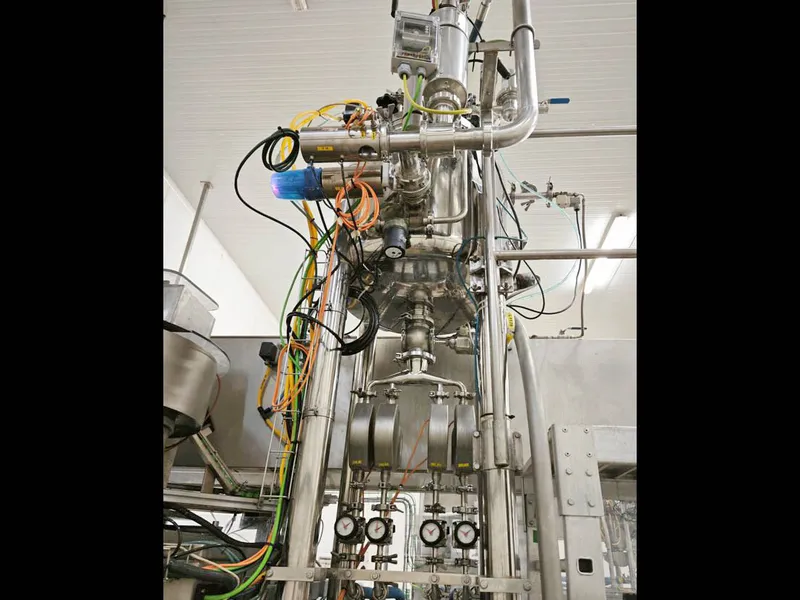

The efficiency of the line is further enhanced by key components from renowned manufacturers. Tetra Pak Contherm, for example, is an excellent heat exchanger used for sterilization, ensuring the product is safe for consumption.

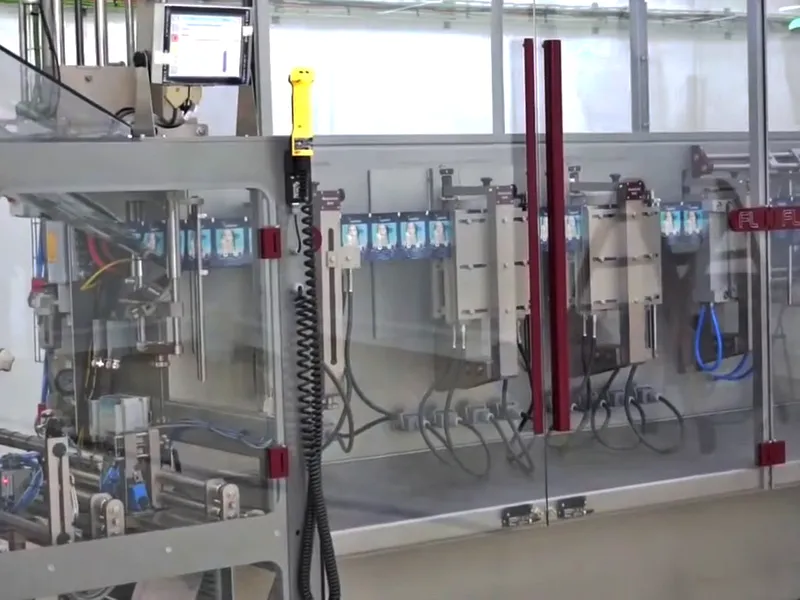

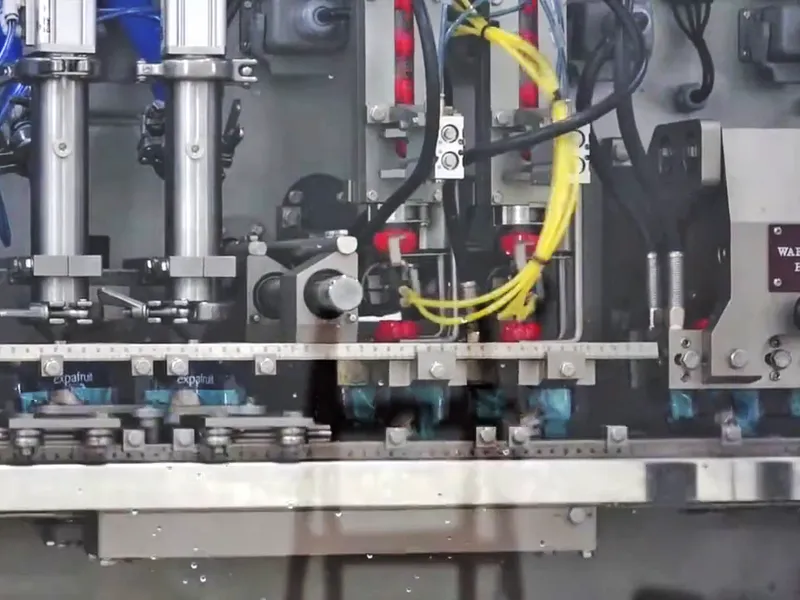

FL TÈCNICS, with its FL 2.2 model, manages filling and packaging with absolute precision. It should be noted that product weight control is managed by Varpe, ensuring that each Doypack pouch is filled with the right amount of product, while RX inspection is also managed by Varpe, offering an additional level of quality and safety.

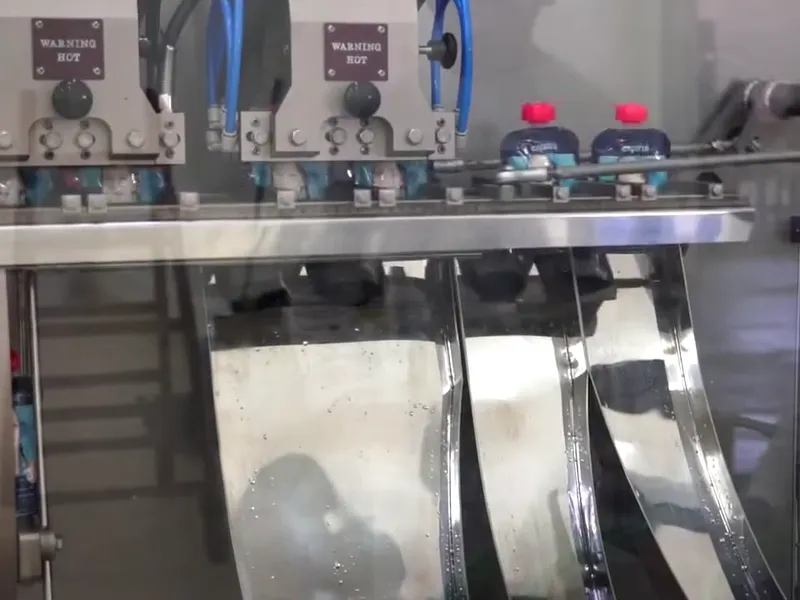

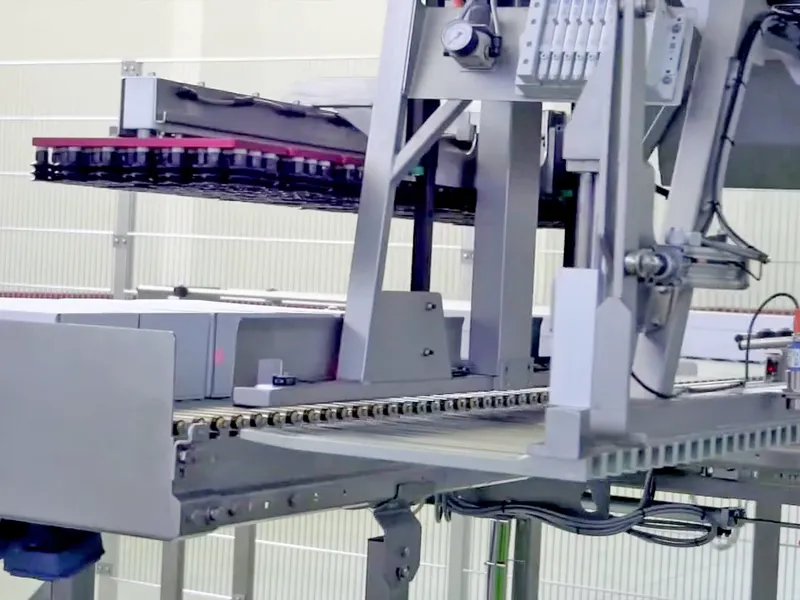

Pasteurization is a key step in any filling process, and in this case, it is handled by an air-type spiral pasteurizer manufactured by Sarp. This ensures that the product is free from pathogens and safe for consumption. The final phase of the packaging and bottling process is managed by Tavil.

The line includes a case erector, a case packer equipped with pick and place grippers, a box sealer for labeling and closing, and finally a robotic palletiser, in order to guarantee maximum precision.

These components work together to ensure that Doypack pouches are properly packaged, sealed and ready for shipping. Although the bottling line is not currently in production, it can be seen in operation, providing a clear demonstration of its capabilities and operational status.

In summary, this pouch filling line combines speed, efficiency and precision in a complete package. Its advanced technical features, assembled from high quality components, make it an ideal choice for those looking for reliable equipment in the bottling and packaging sector.