Description

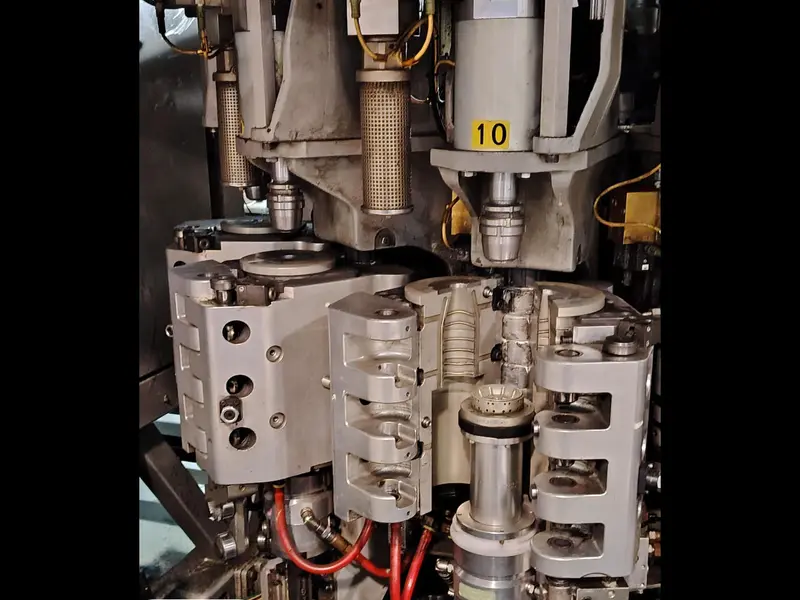

Used Rotary Blow Moulding Machine Sidel SBO 10 Series 1 12.000 bph

Upgrade your bottling process with the used rotary blow moulding machine Sidel SBO 10 Series 1. With a production capacity of 12,000 bph, this machine is designed to increase your efficiency and output.

It comes with essential features such as air recovery, moulds, preform loader, and preforms tipper to simplify your production process. With approximately 50,000 hours in production, this machine has proven its reliability and performance.

Get ready to take your bottling to the next level with the used rotary blow moulding machine Sidel SBO 10 Series 1, which will stop production in September 2021. Don’t miss out on this opportunity to improve your production process and boost your business with this high-quality bottling machine for sale.

Sidel SBO 10 Details.

In the world of bottling, the blow moulding machine plays a crucial role in maintaining the efficiency and quality of production. The Sidel SBO 10 Series 1 machine, a 1998 example, stands out for its ability to process up to 12,000 bottles per hour (BPH), ensuring optimized and reliable production.

Technical features

The Sidel SBO 10 is characterized by its rotary structure, a technological choice that favors constant, high-quality production. This blow moulding machine can process PET containers, a material widely used in the sector due to its versatility and resistance. With ten operating cavities, the SBO 10 ensures efficient production, maintaining excellent quality control on every bottle produced.

Preform Loading and Management System

The SBO 10 blow moulding machine features an integrated preform loading system, ensuring a constant flow and reducing the risk of interruptions during the production process. The system includes a preform tipper and a sorter, which ensure effective organization of the preforms before blowing. The type of pre-formed neck handled by this machine is 28 Alaska, a common choice for many bottling applications.

Air Recovery and Sustainability

An important aspect of this blowing machine is the air recovery system. This feature not only improves the energy efficiency of the machine but also helps reduce the environmental impact of the entire production process. The adoption of sustainable technologies is fundamental in the modern bottling industry, and the SBO 10 responds to this need with its recovery system.

Conclusions

In conclusion, the Sidel SBO 10 Series 1 rotary blow moulding machine represents an excellent solution for companies looking to optimize their PET bottle production. With a speed of 12,000 BPH and a host of features that ensure efficiency and quality, this machine is an ideal choice for those looking to improve their bottling operations. The adoption of this technology not only increases productivity but also demonstrates a commitment to sustainability and innovation in the sector.