Description

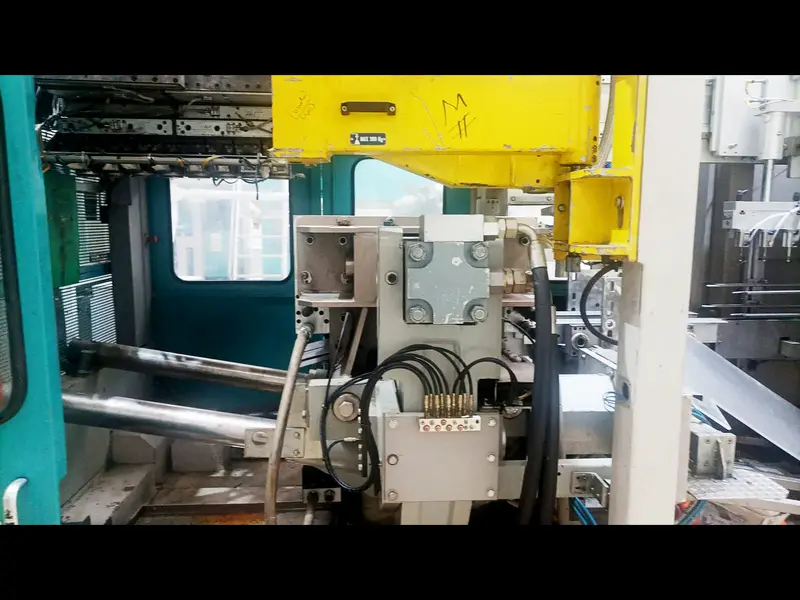

Used HDPE Blow Molding Machine TECHNE 10000SFA up to 1690 bph

The Used HDPE Blow Molding Machine TECHNE 10000 SFA up to 1690 bph advances the field of HDPE container blow molding machines significantly. TECHNE manufactured this machine in 2002, equipping it with cutting-edge technology and technical specifications that make it high-performance and reliable.

Capacity and Implemented Technologies of the HDPE Blow Molding Machine TECHNE

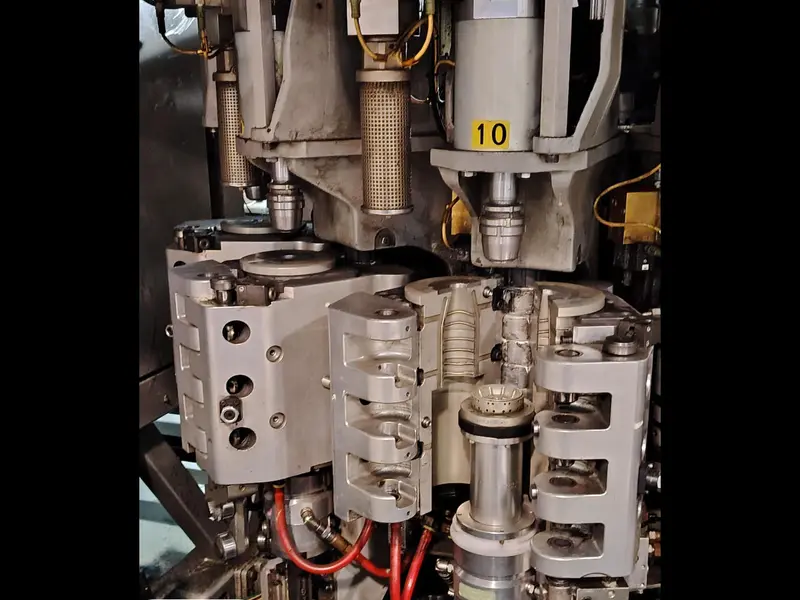

The HDPE Blow Molding Machine TECHNE produces containers with a capacity of up to 1 liter. Additionally, it uses coex-3 layers technology to ensure container quality and consistency. The machine features an 8-cavity extrusion head with a center distance of 105 mm, allowing for efficient production of 8 bottles per cycle. Furthermore, the linear cold blade cutting system and pneumatic pick-and-place system enhance operational efficiency further.

Efficiency and Production Cycle

The HDPE Blow Molding Machine TECHNE achives a nominal production rate of 1690 bottles per hour (bph). The production cycle time is approximately 16 seconds. Consequently, this machine produces 40,560 bottles daily and 13,141,440 bottles annually, based on 324 working days per year. Therefore, the Used HDPE Blow Molding Machine TECHNE 10000 SFA up to 1690 bph suits large-scale operations perfectly.

Detailed Technical Specifications

The machine consists of a single station with extruders of diameters 70 mm/25D, 80 mm/25D, and 60 mm/25D, providing a total output capacity of approximately 320 kg/h. Moreover, DC motors drive the extruders, offering respective power ratings of 33 kW, 41 kW, and 24 kW. The total installed power of the machine is 240 kWh, with an average consumption of 80 kWh. Additionally, the mold’s clamping force is 300 KN, ensuring precise and uniform mold closure.

Controls and Cutting System of the HDPE Blow Molding Machine TECHNE

The control panel allows you to configure and monitor process parameters, including alarm systems. In addition, the machine uses a cold blade parison cutting system and a pneumatic system for bottle pick-and-place. Multiple cylinders control the parison thickness in a closed-loop position cycle, allowing for independent control of the parison profile for each cavity.

Post-Overhaul Performance

In 2013, technicians overhauled the machine, installing a new B&R PLC to enhance performance and reliability. The mold closing mechanism uses levers and hydraulic actuators, strategically positioned to ensure perfect distribution of clamping force. Similarly, upper and lower deflashing occurs through a single pneumatic actuator.

Conclusion of the HDPE Blow Molding Machine TECHNE

The HDPE Blow Molding Machine TECHNE efficiently produces high-quality HDPE containers. Its technical specifications and advanced technologies make it an excellent choice for companies requiring high production capacities and long-term reliability. Furthermore, thanks to its recent overhaul, the HDPE Blow Molding Machine TECHNE offers optimal performance and precise control of production processes.

Optional Accessories:

- Grinders for scraps TRIA mod. BM 5030 SL

- Linear conveyors for scraps

- Angled conveyors for scraps

- MOTAN complete feeding system for machines mod. 10000SFA

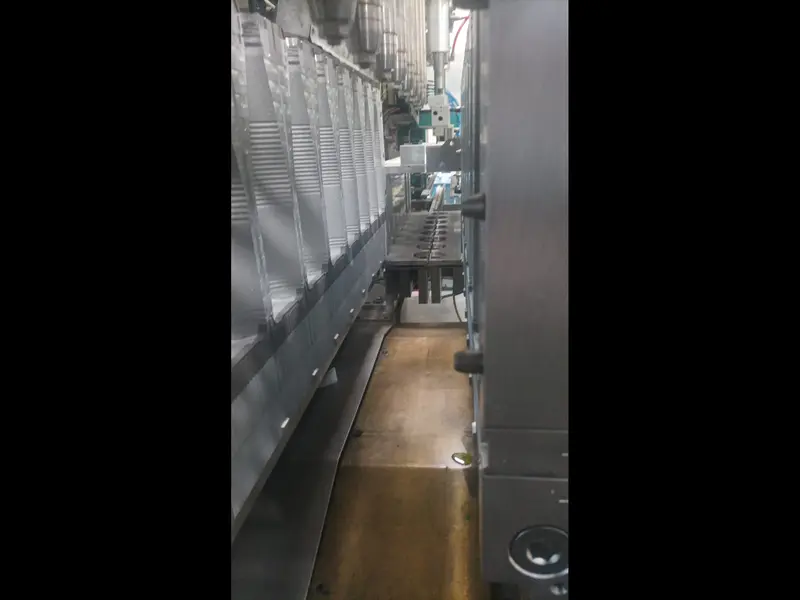

- Conveyors group and parts for bottles receiving and moving

- Chiller Industrial Frigo mod. GR1AC160

- Air compressor Atlas Copco mod. GA 75 VSD+ FF 8153 3258 35