Labeling Machine

Ref: ET192Related machines

Interested in this machine?

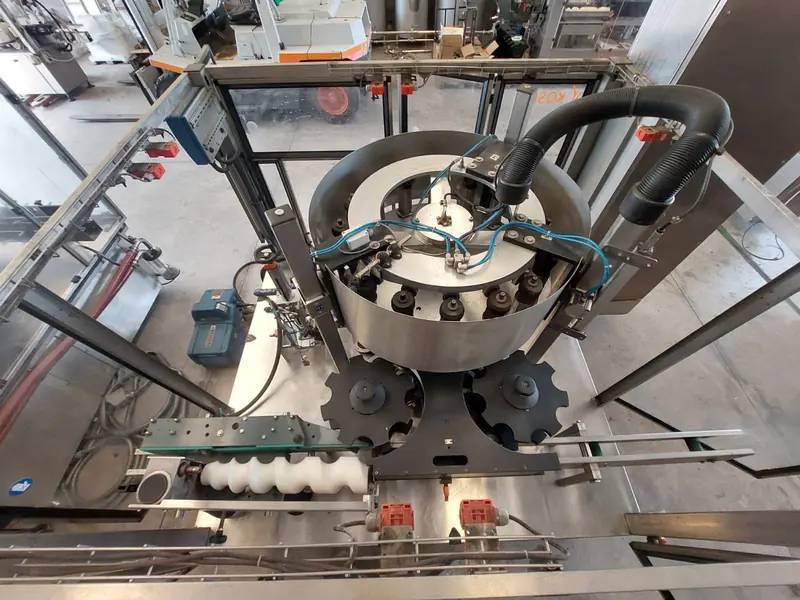

Used Hot Melt Labeling Machine Kosme 20000 bph

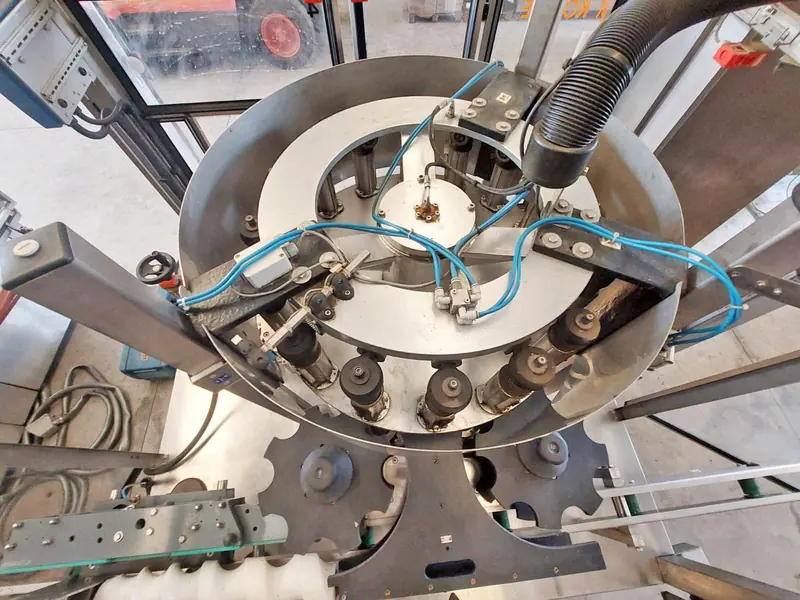

The velocity of this machine reaches max 20,000 bottles per hour (BPH). Kosme works primarily with PET containers, a material extensively used in the beverage industry. The 16 plates have a movement controlled by a mechanical cam system with brake and clutch. This system ensures precision during labeling operations. The single labeling station operates in a clockwise rotation direction.

Type of hot melt system:

From the label application perspective, the labeler uses a hot glue method. This method, although traditional, provides durable adhesion between the label and the container. The Kosme labeler has an Adjustment system related to the different labels manual but has the head adjustments through an electrical system.

Technical specification of the Used Hot Melt Labeling Machine Kosme 20000 BPH:

Other technical specifics include the working diameter, set at 720, with a bottle diameter format of 78 mm, ideal for labeling round bottles. The double auger at the input is a feature that points to the efficiency of the bottle-feeding system.

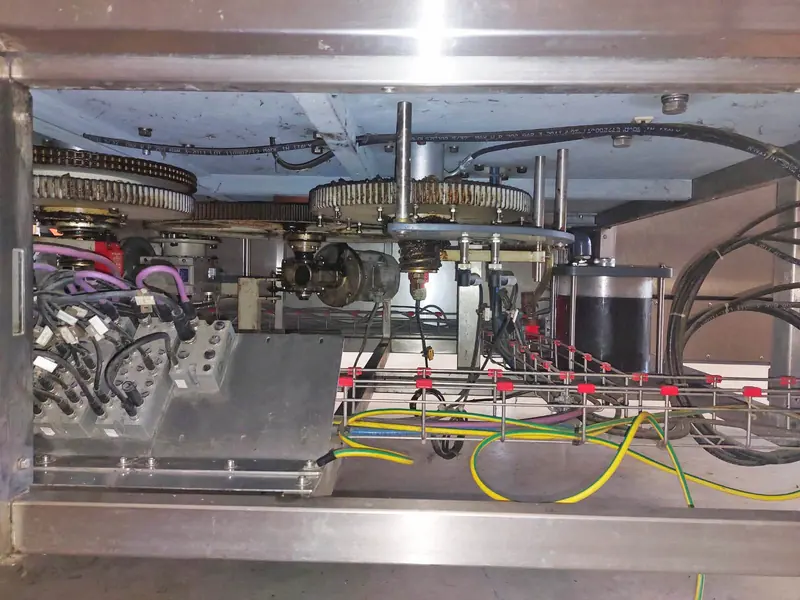

Despite its production year, the machine is currently in storage, suggesting limited use or optimal conservation. Its total weight is 2500 kg, and, from an electrical standpoint, it operates at 400V, with a power of 9kW and a frequency of 50Hz.

The Kosme labeler has the necessary safety features; it is in compliance with current regulations. The usage and maintenance manuals are available, providing further operational details and maintenance techniques.

In summary, with its technical specifications and operational features, the Kosme 20000 BPH hot melt labeler represents an important asset for those operating in the bottling industry and in need of reliable and precise solutions.

Technical assistance:

We can give technical assistance for installing and running this equipment, an offer can be released upon request.