Description

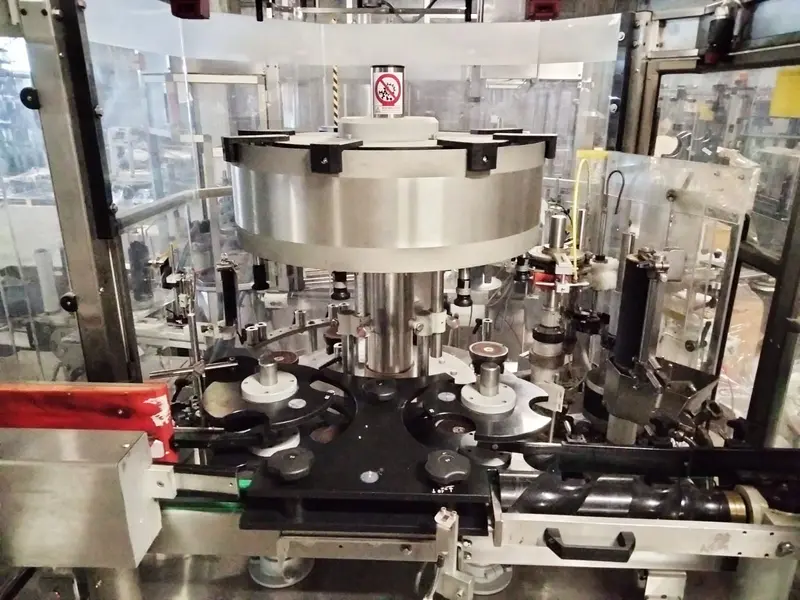

Used Labelling Machine Cavagnino & Gatti Year 2012

Introduction to Production Efficiency of the abelling machine Cavagnino & Gatti year 2012

In the bottling industry, choosing an efficient and reliable labelling machine is crucial. The used Cavagnino & Gatti labelling machine from 2012 stands out. It offers outstanding performance and robustness, making it a preferred choice for industry operators. This article delves into the technical specifications and features of this machine, providing key information for technicians and industry experts.

Technical Specifications of the Model

The model CG-FR-1-8-3RPS-3, produced by Cavagnino & Gatti in 2012, is currently in storage. This model features eight plates with mechanical movement driven by a cam brake/clutch. It highlights the high precision and reliability in label handling. With a production capacity of 4000 bottles per hour (BPH) and designed for glass containers, this machine fits perfectly for 0.75 L bottle formats.

Labelling Methodology and Adjustments

Furthermore, the machine operates with an adhesive and hot glue labelling method. This ensures a wide range of applications for various packaging needs. The label adjustment is automatic, while the head adjustment is manual. Thus, it allows operational flexibility and a high degree of customization in the labelling process. The counterclockwise rotation direction of the machine facilitates integration into existing production lines, further optimizing workflows.

Versatility and Maintenance of the abelling machine Cavagnino & Gatti year 2012

Moreover, the machine is equipped to handle various 0.75 L bottle formats, including standard, European, sparkling, and Burgundy bottles. This shows remarkable versatility in adapting to various product types. Regular maintenance has been performed until January 2023, ensuring the machine maintains high performance and reliability levels.

Configuration and Precise Control

Additionally, the slide carriers of the machine are configured to four axes with manual movement. This offers precise control and facilitates maintenance and adjustments. This feature is particularly useful for ensuring accurate labelling and reducing the risk of errors. This is crucial for maintaining production efficiency and the quality of the finished product.

Conclusion: Added Value for Bottling Operations

In conclusion, the used Cavagnino & Gatti labelling machine from 2012 represents an excellent solution for companies seeking efficiency, reliability, and versatility in the labelling process. With its sturdy construction, high production capacity, and operational flexibility, this machine perfectly meets modern production needs. It offers significant added value to bottling operations.