Used Filling Monoblock Galdi Up to 6000 BPH

Introduction to Advanced Bottling Technology

Initially, the Galdi RG260A, a high-performance filling monoblock from 2010, stands as a cornerstone of modern bottling operations. Having been recently overhauled, it showcases unmatched efficiency and reliability. Consequently, achieving speeds of up to 6,000 bottles per hour, this machine sets a benchmark in the industry. Specifically, it is engineered for Pure-Pak Daimond Standard Curve B-style T-Bottom containers. Moreover, it utilizes 36mm Elocap caps, demonstrating its versatility and adaptability to various packaging needs.

Ensuring Uncompromised Product Safety of the Filling monoblock Galdi

Importantly, one of the critical aspects of the Galdi RG260A is its disinfection killing rate. With up to LOG5, it guarantees the highest levels of product safety. This capability is especially crucial in today’s market, where consumer health and safety are paramount. Therefore, the machine’s design and operational protocols are aligned with strict hygiene standards, offering peace of mind for producers.

Adaptable to a Wide Range of Products

Furthermore, the machine’s flexibility is highlighted by its capacity to handle multiple packaging cross-sections. From 500 ml to 1000 ml, it accommodates various product volumes. This adaptability extends to the machine’s ability to process a diverse array of products. Whether dealing with dairy, juice, liquid food, or high-viscosity substances, the Galdi RG260A stands ready. Additionally, its design supports products containing particles and fibers, ensuring smooth operation without compromising quality.

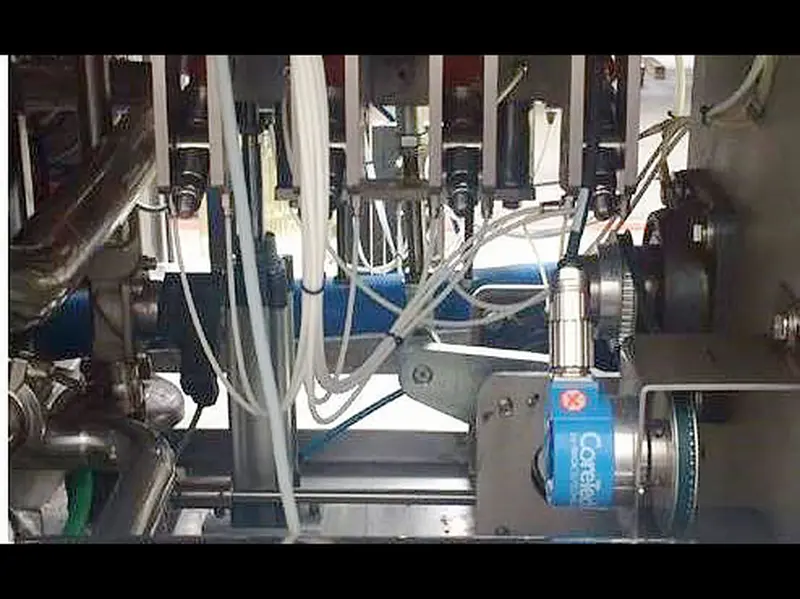

Customization and Efficiency in Chilled Distribution

Moreover, tailored to meet specific customer requirements, the machine features a 36 mm XE cap applicator. It also includes a cap feeding system, enhancing operational efficiency. The inclusion of a CIP return pump underscores the machine’s commitment to hygiene and easy maintenance. By employing gravity or light depression filling, it ensures accurate and gentle handling of products.

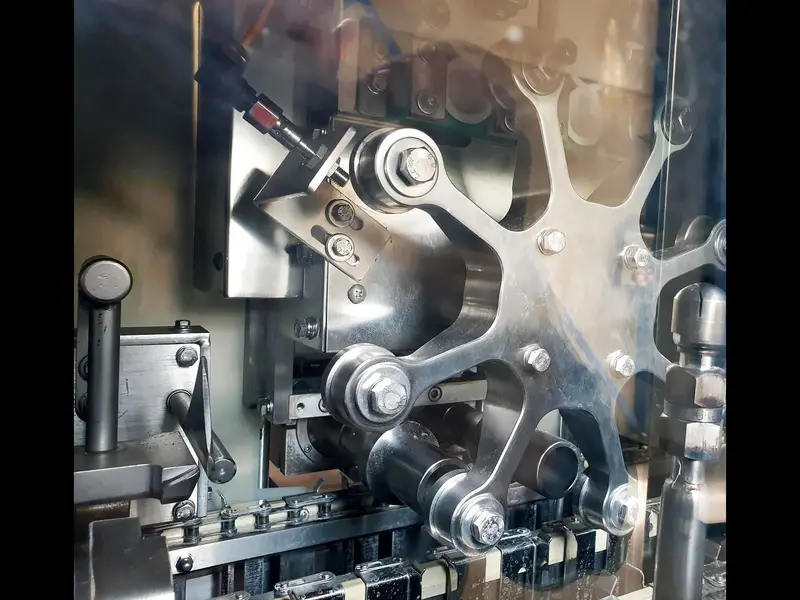

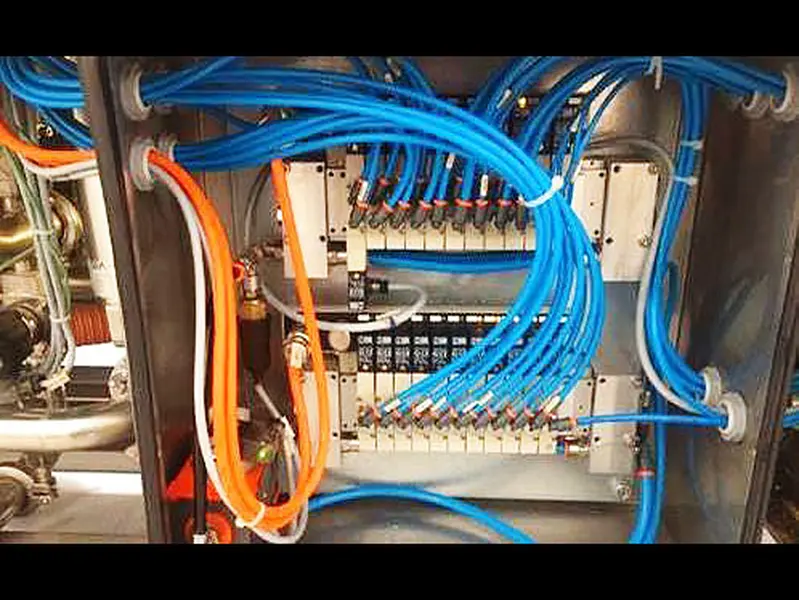

Technological Excellence for Optimal Performance

Additionally, the Galdi RG260A is equipped with advanced technological components. These include a double indexing magazine and a LOG5 killing rate sterilization system. Sterile air filters and a servo-driven cross cap applicator contribute to its superior performance. The aseptic double diaphragm filler, with specialized intake and discharge valves, ensures hermetic sealing from external environments.

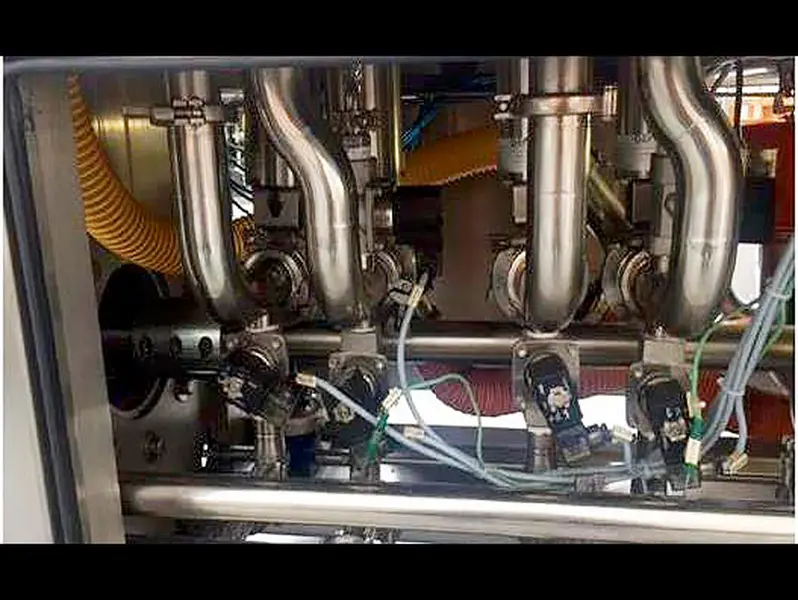

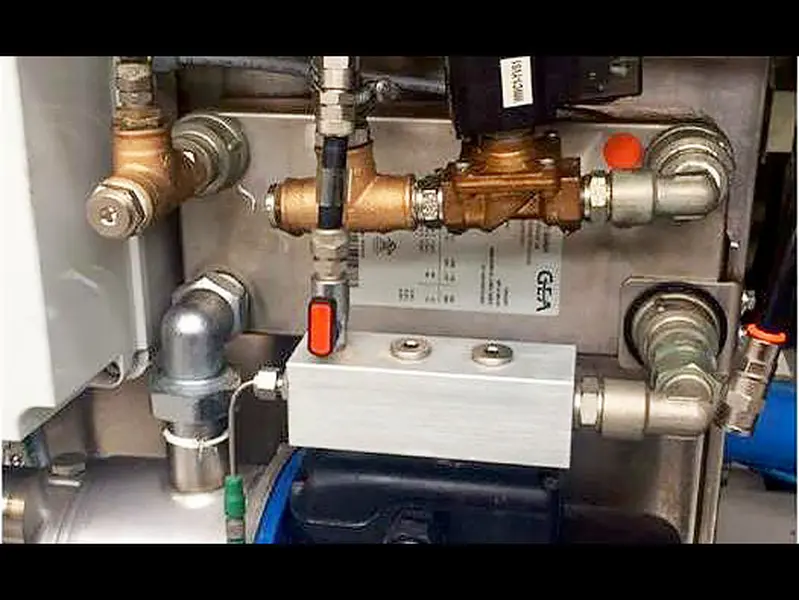

Innovative Filling Solutions of the Filling monoblock Galdi

Furthermore, the machine employs a bottom-up filling system, designed to reduce splash and foam. This approach is critical for maintaining product integrity and appearance. A special closed filling box for the aseptic filling room and automatic CIP-SIP system further enhance sanitary conditions. Pressurized by sterile air steam, the system maintains a sterile environment throughout the filling process.

Universal Compatibility and Energy Considerations

Lastly, the universal transport chain accommodates all carton configurations, emphasizing the machine’s adaptability. With an operational consumption of 400 V, 69 Kw, 50 Hz, the Galdi RG260A also highlights energy efficiency. This efficiency is vital for reducing operational costs and supporting sustainable production practices.

Concluding Remarks on Bottling Innovation

In summary, the used Galdi RG260A filling monoblock represents a significant advancement in bottling technology. By combining high-speed operation with flexible product handling and stringent safety standards, it offers a comprehensive solution for modern bottling needs. Its recent overhaul ensures that this machine will continue to serve the industry’s evolving demands, making it an invaluable asset for any operation aiming to enhance efficiency and maintain high-quality standards in their bottling processes.