Description

Combiblock Sidel universal type Isobaric system 2 model 14-100-15 year 2010, excellent opportunity

Bottle formats size available:

- 0.5lt round bottle

- 1.0lt round bottle

- 1.5 lt round bottle

- 1.5lt square bottle

- 2.0lt square bottle

Builder: Sidel pet blowing machine

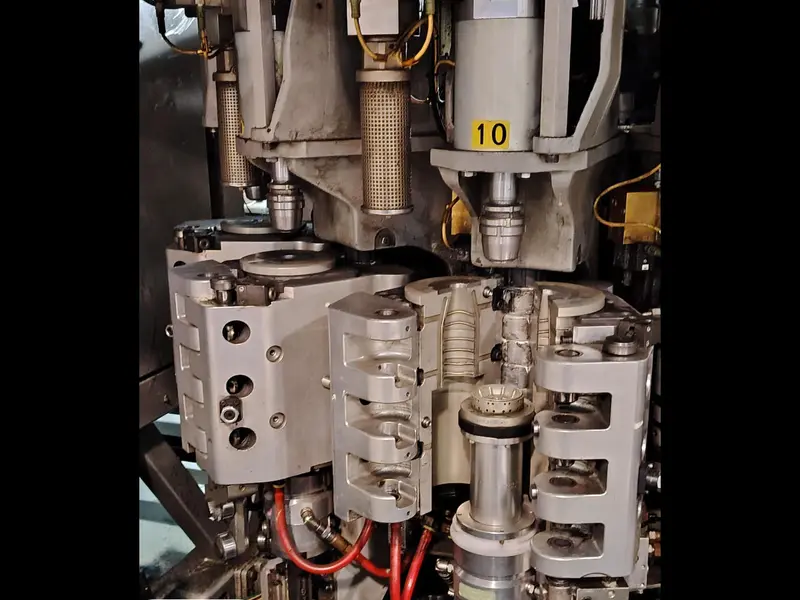

Used Blow molding machine model Universal 2 SBO 14

These used Filling machine model Eurotronica FM – C with capper manufacturer Arol

Year of construction: 2010

Used Sidel Universal Combi Model: 14 – 100 – 15

Bottleneck type: Alaska / Corvaglia

Nominal production Sidel pet blowing machine: 28,000 BPH

Hours of work: 40,000

Machine complete with:

- Octabin tipper

- Preform orientator

- Caps elevator

- Level and cap bottle inspector

- Blow molding machine

- In production until October 2021 with a very good status of maintenance.

Speed and technical specification:

The machine combi block Sidel Universal has excellent condition and still produces about 25000 b/h on a 1,50L. That is based on still water and sparkling water on 1.50L and it is possible to create dedicated equipment, but it is not only for Combiblok Sidel Universal but for all the blower equipment for PET.

That’s on request both to change the preform neck; for example, from a neck 28 for natural water like Alaska to a PCO 1881 neck for drinks.

It is possible to create equipment for different bottle diameters and construction of new molds also providing all the advice. That’s to optimize the design requested by the customer.

Spare part of Combiblock Sidel universal:

It is also possible to supply spare parts of Combiblok Sidel Universal. This is both for the preform blower part and for the filler and capper part. However, some maintenance is recommended before putting the Used Combi Sidel Universal back into operation.

In order to be able to produce without added time after disassembly, certain maintenance is recommended. That maintenance of Sidel pet blowing machine is quantified after one inspection of our technicians.

How it’s the time to supply the required spare parts for the Combiblock Sidel Universal? It is variable from 1 to 3 months so we use our workshops to build the most part of these.

After that, the components and design will be tested in the intervention on the machinery.