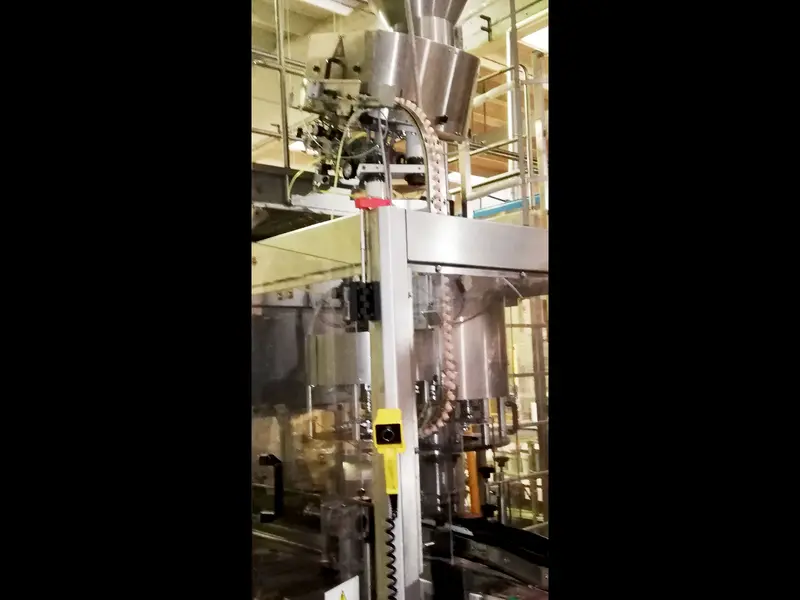

Capping Machine

Ref: TP91Related machines

Interested in this machine?

Advanced Functionality for Optimal Performance

Significantly, this specific capper is marked by advanced features. Its adjustable-height capping head, a key element, allows adaptation to different bottle sizes and shapes. Consequently, this flexibility maintains consistent capping quality across production lines. Moreover, the cap distribution system, using an innovative cellular centrifugal distributor, guarantees a steady cap supply. This aspect is essential for maintaining the impressive 7000 BPH output, ensuring uninterrupted production.

Safety Features and Robust Design

In terms of safety, the AROL KAMMA is exceptionally well-equipped. It includes comprehensive safety measures to prevent accidents and protect operators. Additionally, its construction with high-grade stainless steel isn’t just durable; it also eases cleaning and maintenance. This robust design is vital for continuous operation at high speeds, especially crucial given the substantial 7000 BPH output.

Operational Flexibility and Efficiency

Regarding operational flexibility, the AROL KAMMA excels. Its speed can be precisely adjusted using an inverter, allowing pace customization for specific production needs. This adaptability ensures seamless integration into various bottling lines with differing speeds and configurations. Also, the bottle entry, designed for left-hand (clockwise) flow, fits a wide range of production setups.

Conclusion

To conclude, the 1999 KAMMA capping machine, capable of handling 7000 BPH, is a superior choice for demanding bottling needs. It combines speed, precision, adaptability, and safety, making it essential for businesses aiming to boost bottling efficiency and reliability. Lastly, the machine’s lasting design and advanced technology make it a wise investment for companies.