Description

Used capping machine Clean Pack up to 2500 bph

Machine Specifications

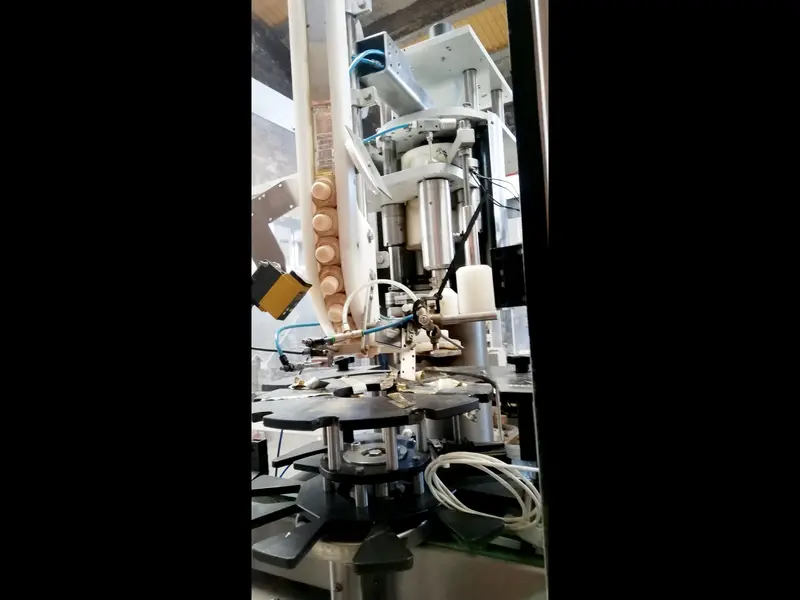

Firstly, the CLEAN PACK brand capper features a single-head configuration, specifically designed for applying T-caps. Importantly, this technical choice allows for precise cap placement, which is essential for ensuring the integrity of the bottled product. Moreover, the cap distribution system operates through vibration mechanisms, an effective method for sorting and feeding caps to the capping device without interruptions.

Speed Adjustment of the Used capping machine Clean Pack up to 2500 bph

Secondly, the production speed of the capper is adjustable via an inverter. This allows fine control of the capping rate, tailored to the desired production rhythm. Consequently, this adjustment capability proves particularly useful in dynamic production environments, where requirements can quickly change.

Configuration and Safety

Additionally, the bottle entry flow is thoughtfully designed to come from the left, a configuration that adapts to different line arrangements. Furthermore, integrated safety protections in the machine’s design are a crucial aspect, aiming to minimize operational risks for the bottling line operators.

Materials and Maintenance of the Used capping machine Clean Pack up to 2500 bph

Similarly, the capper is constructed with a painted frame and stainless steel cladding. This choice not only provides robustness to the machine but also facilitates its cleaning and maintenance. Notably, stainless steel is known for its corrosion resistance, ensuring a long operational life of the machinery in humid environments.

Production Capacity and Bottle Format

Equally important, suitable for rectangular-shaped bottles, the capper achieves a production capacity of about 2,500 bottles per hour. This data highlights the system’s efficiency in handling high production volumes, maintaining precision standards in capping. Additionally, the machine is supplied with an existing bottle format, facilitating integration into pre-existing production lines.

Operational Conditions and Year of Production

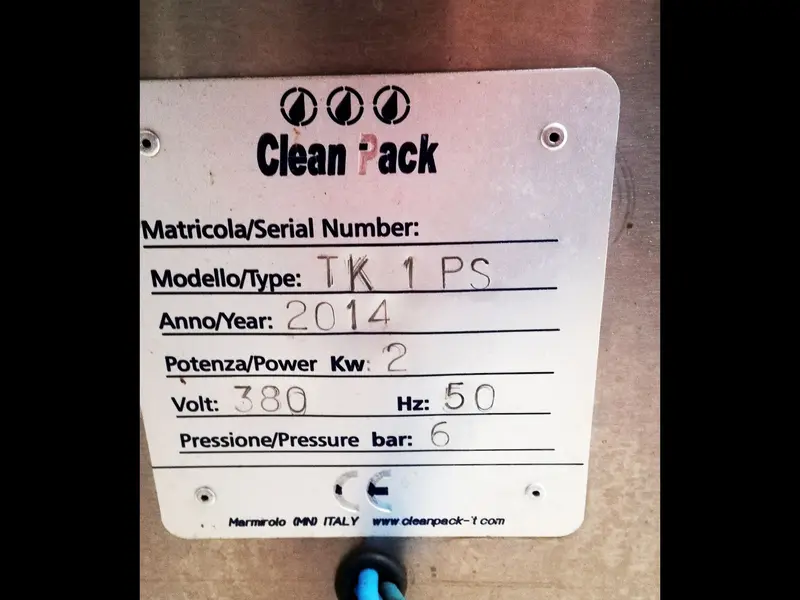

Finally, produced in 2014, this machine has seen limited use, a condition that preserves its original efficiency and reliability features. The infrequent use of this capper ensures that the machinery maintains optimal performance, representing a valuable resource for bottling processes that require high precision and reliability.

In summary, after careful consideration, the technical analysis of the used CLEAN PACK capper up to 2500 bph reveals an advanced equipment. It is characterized by engineering solutions aimed at productive efficiency, operational safety, and ease of maintenance. Its ability to adapt to different production rhythms and bottle formats makes it a versatile choice for the bottling industry.