Description

Used Blow Molding Machine KOSME KSB 4L up to 6800 bph

The KSB 4L blow molding machine is built specifically for producing PET bottles. Notably, it offers a robust, compact solution for high-performance production. Its design is both innovative and technically straightforward. As a result, it ensures optimal efficiency and a high quality-to-price ratio. With four cavities, it effectively produces up to 6,800 bottles per hour. In addition, it accommodates formats from 0.1 to 2.5 liters. The solid, well-organized structure of the KSB 4L provides operators with flexibility and reduced maintenance needs. Furthermore, the machine has completed 22,000 hours of operation. It also includes two original molds, one for 0.5 liters and one for 1 liter.

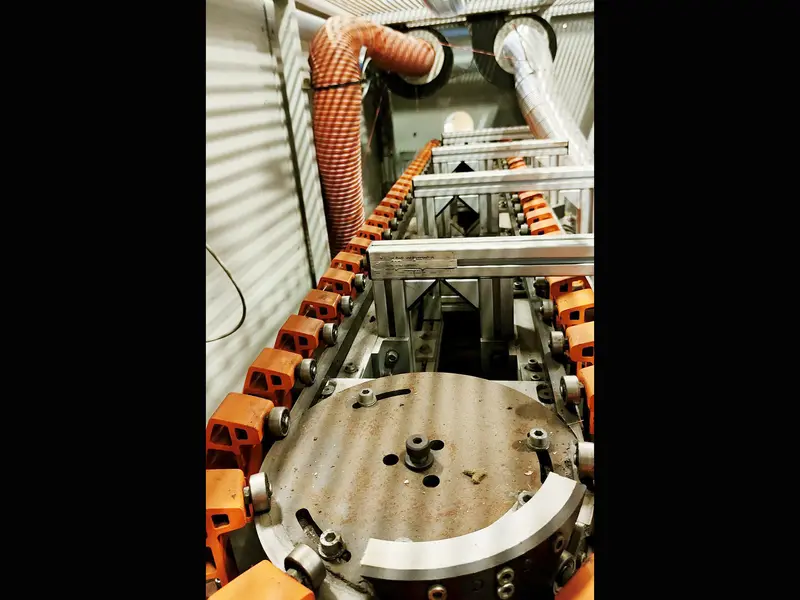

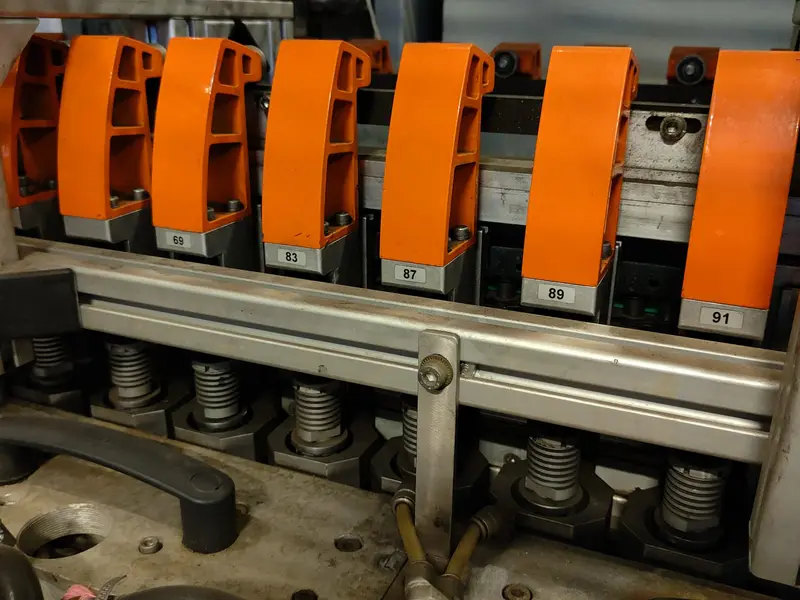

Heating system and preform feed in the Blow Molding Machine KOSME KSB 4L

To achieve its heating capabilities, the KSB 4L’s heating system uses four heating modules and eight heating zones.It provides a heating capacity of 46 kW. Moreover, its patented positioning system places infrared lamps precisely, thereby ensuring optimal external heating of preforms without opening the oven. For efficiency, the conveyor belt system for preform feed orients and positions the preforms. It streamlines the heating process and thus reduces preparation times.

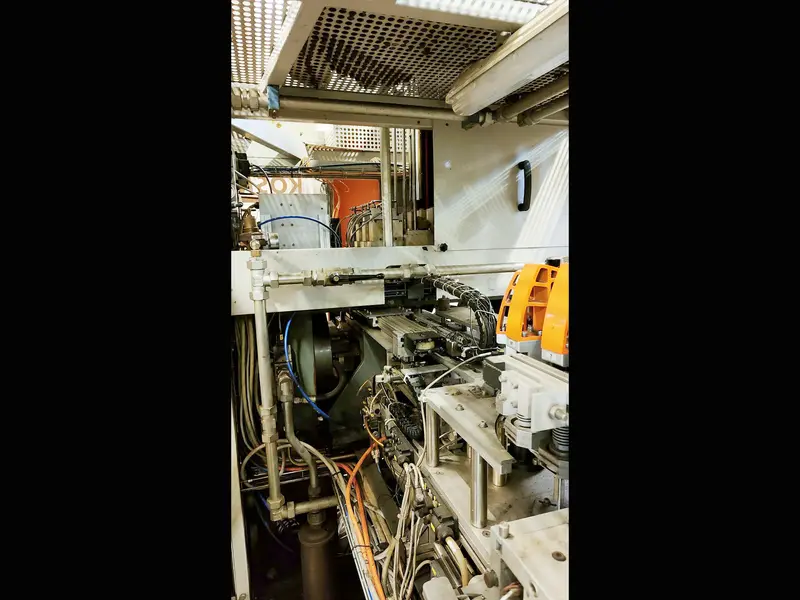

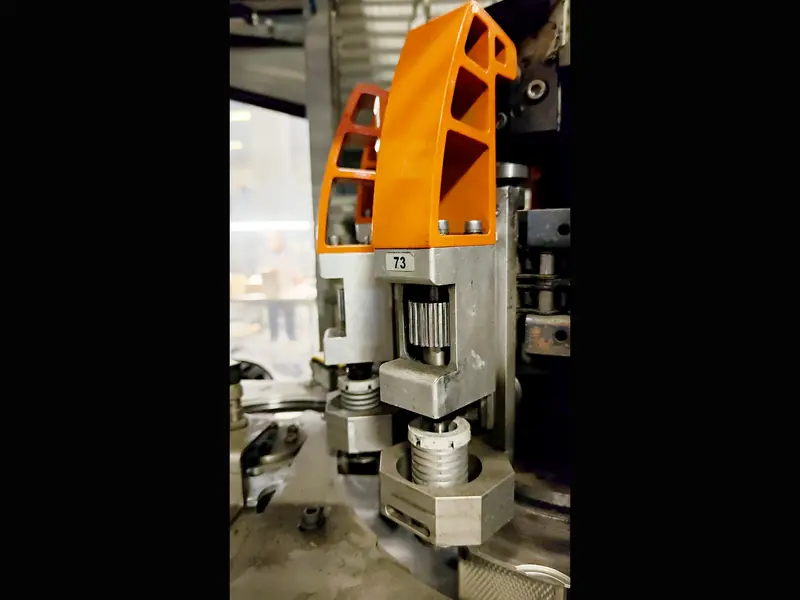

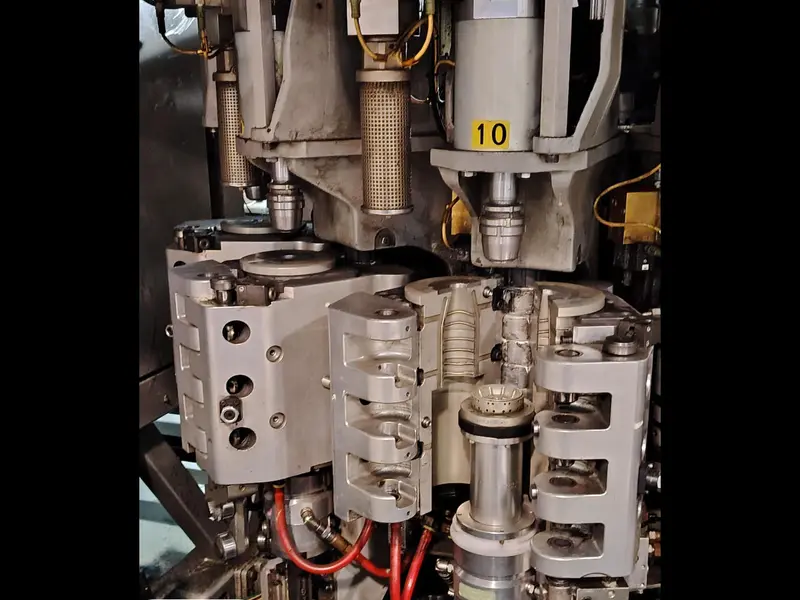

Blowing process and production efficiency

Furthermore, the Blow Molding Machine KOSME KSB 4L’s pneumatic preform separation system adjusts the preforms’ distance from 40 mm in the oven to 120 mm in the mold. Then, the blowing process operates in a fully replaceable station, which adapts to different bottle diameters as needed. Afterward, the transfer unit moves heated preforms into the mold cavities, where they undergo sealing, stretching, and blowing. Each cavity consequently produces up to 1,700 bottles per hour, thereby achieving high precision and stability in production.

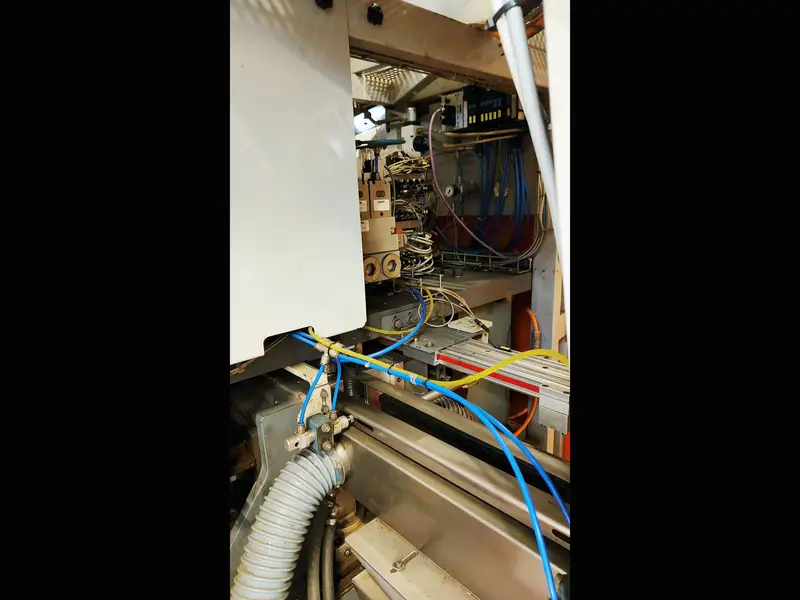

Consumption and energy requirements

In terms of energy, the KSB 4L operates on a voltage of 3 x 230/400 V, with a frequency of 50 or 60 Hz, an installed power of 56 kW, and an average consumption of 36 kW. Additionally, the compressed air system maintains a working pressure of 10 bar and a blowing pressure up to 40 bar, consuming 470 Nm³/h of air. In addition, the cooling system requires a water flow of 6.6 m³/h at an inlet temperature of 5 to 7 °C, achieving a cooling capacity of 20.8 kW.

Operator advantages and maintenance

Notably, the design allows easy access to all internal components, thereby enabling quick format changes and simplifying mold replacement, which takes an average of only 30 minutes. Furthermore, its linear movement arrangement and durable construction materials minimize maintenance needs. Additionally, the touch-screen interface lets operators input parameters for different types of preforms and bottles, and the system offers password protection to enhance operational security.

Conclusion of the Blow Molding Machine KOSME KSB 4L

In conclusion, the KSB 4L serves as an ideal solution for those seeking a reliable and high-performance used machine that produces PET bottles with precise specifications and optimized consumption. With a capacity of 6,800 bottles per hour, the machine consistently meets high standards of productivity and quality, catering to the bottling industry’s needs with both efficiency and flexibility. Finally, the package includes two original molds, one for 0.5 liters and one for 1 liter, adding versatility to production capabilities.