Description

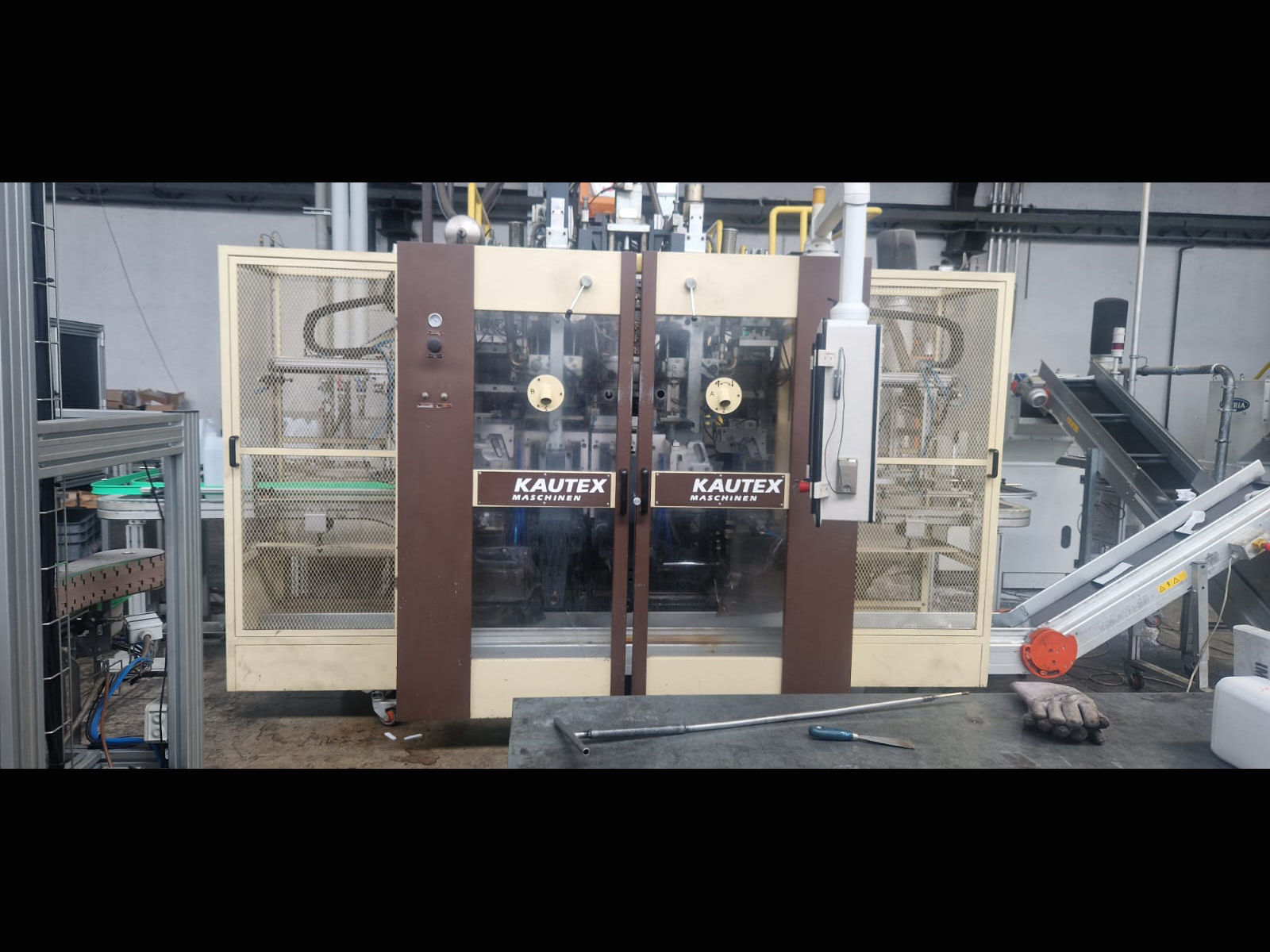

Used Blow Molding Machine HDPE Kautex KCC5D year 2012

Introduction to the HDPE Blow Molding Machine Kautex

The HDPE Kautex KCC5D blow molding machine debuted in 2012, enabling the automatic production of hollow articles from thermoplastic materials, with a nominal speed of 600 bph. Furthermore, this double-station model integrates a solid structure that combines a machine frame, extruder frame, and rear control cabinet. The mold carriage moves horizontally on linear roller guides, allowing the mold to open and close in parallel, generating clamping force rapidly, and varying mold thickness. Consequently, the system supports continuous high-speed extrusion. It is designed to process formats ranging from 5L to 2L.

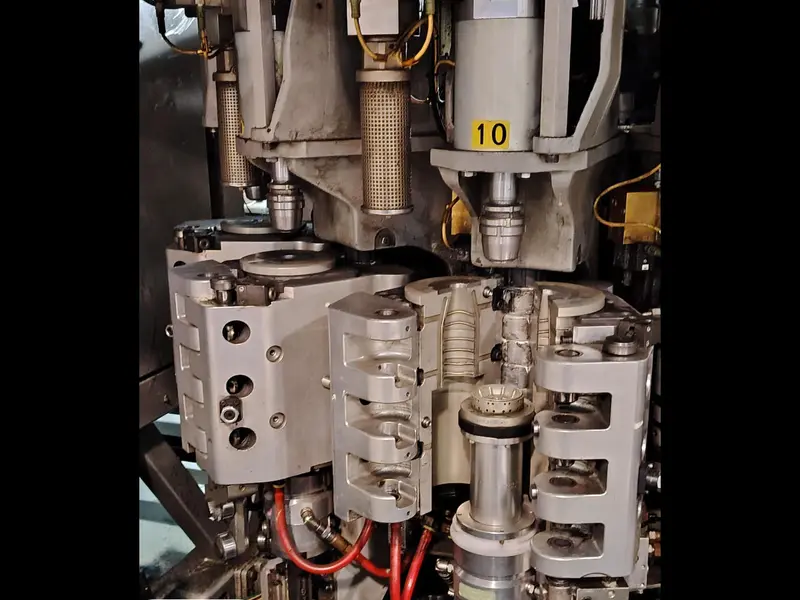

Clamping Unit Specifications

The clamping unit handles a force of 60 kN and accommodates molds with dimensions of up to 310 mm in width and 400 mm in length. Moreover, operators can adjust the plate distance from 200 mm to 460 mm. Additionally, the carriage completes a 320 mm stroke and supports molds weighing up to 2×100 kg. An integrated hydraulic system ensures precise and rapid carriage movement. As a result, the unit maintains high efficiency.

Hydraulic System

The hydraulic unit delivers energy-efficient performance with its dual-circuit system and accumulators. Moreover, internal gear pumps operate quietly. A heat exchanger cools the oil, while electronic monitoring systems track oil levels and filter contamination. Therefore, the hydraulic system ensures reliability and longevity.

Extruder Platform

Operators access the extruder platform via side stairs, using the electric height adjustment system to simplify maintenance and adjustments. Furthermore, safety barriers meet European and American standards, creating a secure working environment. Thus, operators benefit from enhanced safety measures.

BlowCommand 4 Control System

The BlowCommand 4 control system employs a PC with real-time Soft PLC and a 15-inch color touchscreen display. This system streamlines function management, including axial wall thickness adjustment through 100 control points. Additionally, advanced capabilities include managing night heating, storing data on Compact Flash, and performing remote diagnostics via modem. Consequently, these features optimize machine operations.

Included Equipment

The machine incorporates two sets of calibration devices with proportional hydraulic control, a cold cutting and welding system for parisons with electropneumatic control, and punching devices for neck, shoulder, and handle cooling with pneumatic assistance. Moreover, it also includes bottom punching devices featuring pneumatic spring support and vertical adjustment. Furthermore, two sets of post-cooling devices manage internal air flow, making the system suitable for single or multiple productions. Therefore, this comprehensive equipment ensures versatility.

Documentation and Operator Panel

The standard documentation details the machine’s operational specifications comprehensively. Additionally, a swivel-mounted operator panel enables full control over essential functions, including screw speed, cycle time, and operating hour count. As a result, operators can efficiently monitor and adjust operations.

Conclusion of the HDPE Blow Molding Machine Kautex

This 2012 model empowers operators with advanced capabilities for producing hollow thermoplastic articles, with a speed of 600 bph. Moreover, it combines innovative features with operational safety, offering a reliable and efficient system. Consequently, the machine proves ideal for various industrial applications.