Description

Used HDPE Extrusion Blow Molding Machine for 10 L – 300 bph – Overview

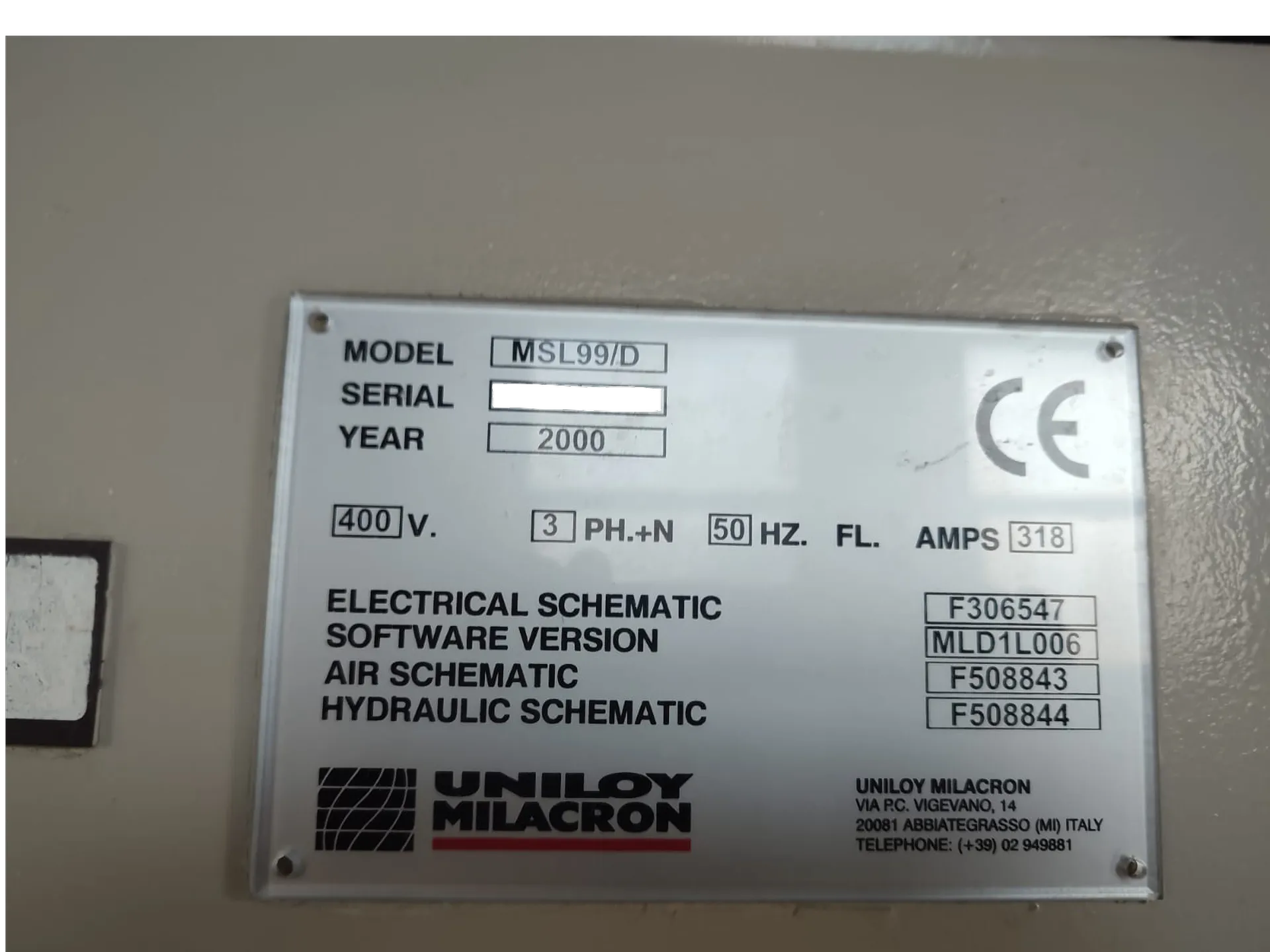

Second-hand Uniloy Milacron HSM10/D extrusion blow molding machine designed for producing up to 10 L HDPE containers. With a single-parison head and robust clamp, this EBM unit is ideal for industrial packaging and beverage production auxiliaries (e.g., water canisters, edible oils) and can be integrated within a used bottling line. Documentation and manuals are available. Reference number: SO126.

Technical Specifications & Performance Data

Main data

- Make/Model: Uniloy Milacron HSM10/D

- Year: 2000

- Technology: Extrusion Blow Molding (EBM), single parison

- Material: HDPE

- Number of cavities: 1

- Max container volume: 10 L

- Indicative output: up to about 300 bph on 10 L (application-dependent)

- Manuals: included

- Ref. no.: SO126

Extruder

- Screw diameter: 100 mm; L/D 24

- HDPE screw speed: 0–70 rpm

- Plasticizing capacity (HDPE): approx. 300 kg/h

- Main extruder motor: 89 kW

- Heating zones: 6; barrel heating power: 31.4 kW

- Motor cooling power: 0.58 kW; barrel cooling power: 1 kW

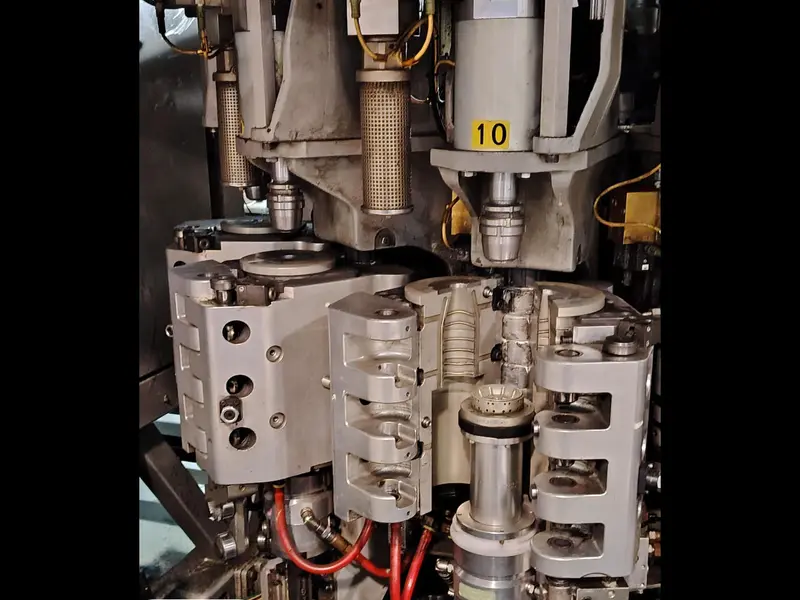

Parison head

- Type: PE 1/200, single parison

- Max die diameter: 200 mm

- Head heating power: 14.2 kW

- Parison thickness control: hydraulic (wall-thickness programming)

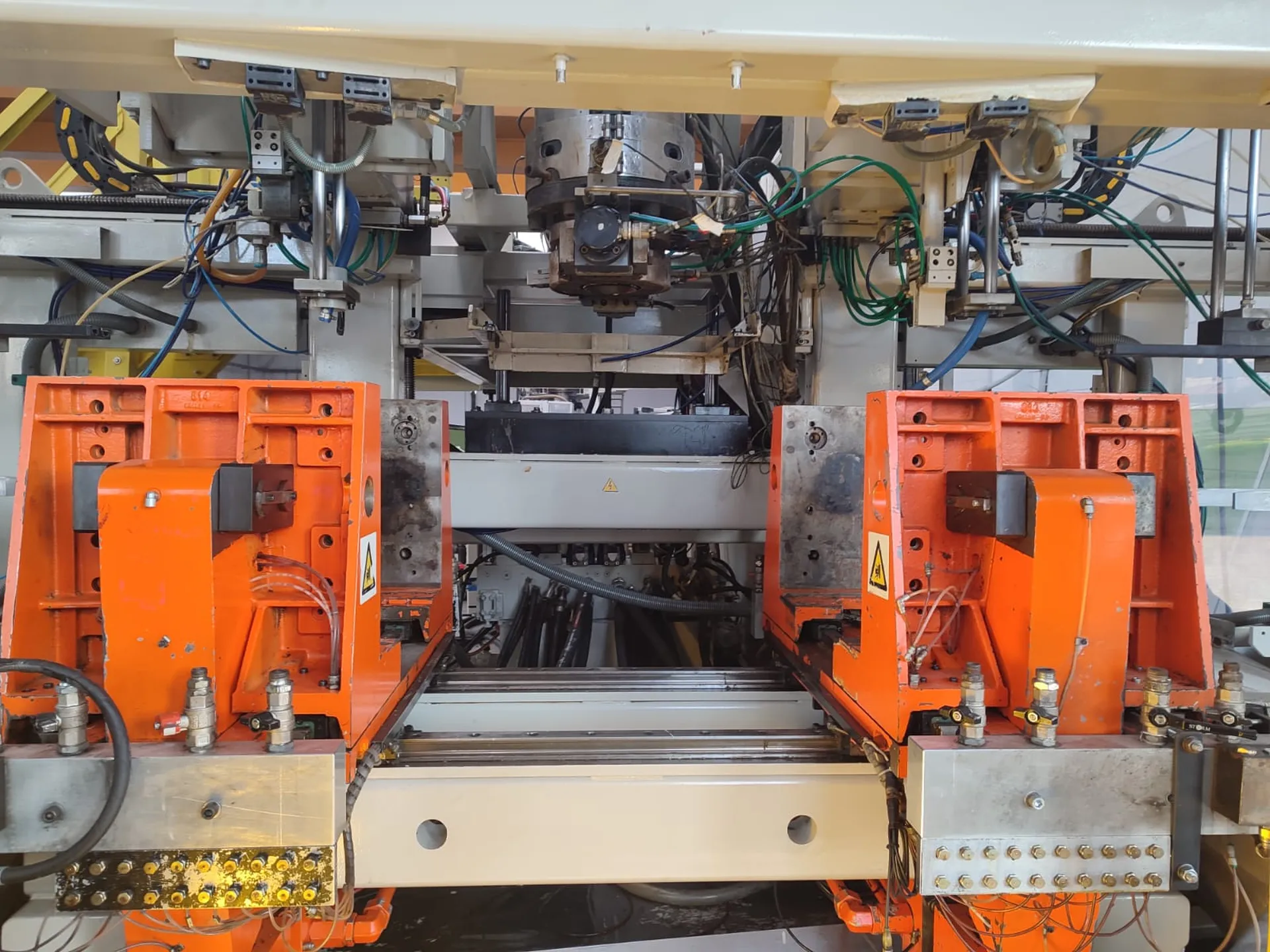

Clamp & blow unit

- Clamp force: 200 kN

- Max mould size: 650 × 500 mm (H)

- Mould thickness: 2 × 150 mm

- Mould opening stroke: 300 mm

- Horizontal carriage stroke: 660 mm

- Blow pin stroke: 240 ± 5 mm

- Blow pin thrust at 50 bar: 320 kg

Electrical

- Installed power: 156 kW (average consumption ~104 kW)

- Supply: 400 V, 50 Hz, 318 A, 3 + N

Hydraulic system

- Reservoir capacity: 400 l

- Pump flow (1470 rpm): 123 l/min

- Max pressure (main circuit): 190 bar

- Main hydraulic motor: 37 kW; oil cooling motor: 1.5 kW

Pneumatics

- Operating pressure (general): 6–8 bar; air use: 2000–2500 Nl/min

- Post-cooling pressure: 6–8 bar; air use: 1000–1500 Nl/min

Cooling water

- Mould circuit: 8–12 °C; flow 15 m³/h

- Extruder & hydraulic oil: 10–24 °C; flow 4 m³/h

Dimensions & weights

- Approx. machine size (L × W × H): 7600 × 7700 × 3900 mm

- Blow unit weight: 7600 kg; Extrusion group weight: 6400 kg

- Noise level at operator: < 85 dB(A)

Advanced Automation & Control Systems

- Hydraulic wall-thickness programming for precise parison control, improving weight distribution and top-load performance on 10 L containers.

- Dedicated Uniloy command and control software (version code available in manuals) with operator interface for setpoint management and diagnostics.

- Integrated temperature control across six extruder zones and heated head for stable processing at up to 300 °C transformation temperature.

- Interlocked guarding and emergency stops for safe operation.

Production Line Integration Capabilities

This second-hand extrusion blow molder is integration-ready for downstream equipment typical of a used bottling line and industrial packaging systems:

- Conveyors, deflashing/trimming, leak testers, vision/weight control, and palletizing cells.

- Standard utilities: 400 V / 50 Hz electrical, 6–8 bar compressed air, closed-loop cooling water at specified flows.

- Suitable for beverage production auxiliaries such as water and edible-oil jerrycans, as well as chemicals and household products.

Machine Condition & Maintenance History

- Status: second-hand unit with original documentation; manuals are available for commissioning and maintenance.

- Chiller: not supplied (water circuits required as per specs). Air compressor: not included unless otherwise stated.

- Inspection and test under your product and tooling are recommended to validate cycle time and wall-thickness distribution.

Operational Performance & Versatility

- Single-parison design supports consistent production of 5–10 L containers with changeable dies up to Ø200 mm.

- HDPE processing at high plasticizing capacity (~300 kg/h) enables competitive cycle times around 300 bph on 10 L, subject to mould design, cooling, and part geometry.

- Stable temperature control and hydraulic parison programming deliver repeatable quality for demanding industrial packaging requirements.

Installation Requirements & Site Preparation

- Footprint and access: allocate at least 7.6 × 7.7 m plus service clearance; height 3.9 m minimum.

- Electrical: 400 V, 50 Hz, 3+N, 318 A; installed power 156 kW (typical average ~104 kW).

- Compressed air: 6–8 bar; 2000–2500 Nl/min for process plus 1000–1500 Nl/min for post-cooling.

- Cooling water: mould circuit 8–12 °C at 15 m³/h; extruder/oil circuit 10–24 °C at 4 m³/h. Provide adequate filtration and water treatment.

- Floor loading: allow for approx. 14 t total machine mass across extrusion and blow groups.

Safety Standards & Compliance Certification

- Safety features include interlocked guards, emergency stop circuits, and acoustic emissions below 85 dB(A) at the operator position.

- Built to European safety practices of its manufacturing period. Compliance with current local regulations should be verified during installation.

- Comprehensive manuals support risk assessment, CE validation updates, and operator training.