Description

Neck: Max.45/55 mm.

Production: 5000 bph

Max volume: 8.000 ml.

Mold pitch 200 mm

Machine. operating 24 hours – well maintained

Automatic cycle time: 32978 h – Blown bottles: 49.893.049

The machine is in good general condition in terms of maintenance and use.

In general, it does not require, at least visually, thorough maintenance, from verification made on our archives, the customer purchased in 2009/2010 and 2014 some components of the manipulator, rack-pinion and transport motorization, also in this case autonomously provides maintenance . The machine needs a general cleaning in the zones of greasing movement bottoms, toggle and ironing from what has been seen, following some general considerations on the status of some fundamental groups:

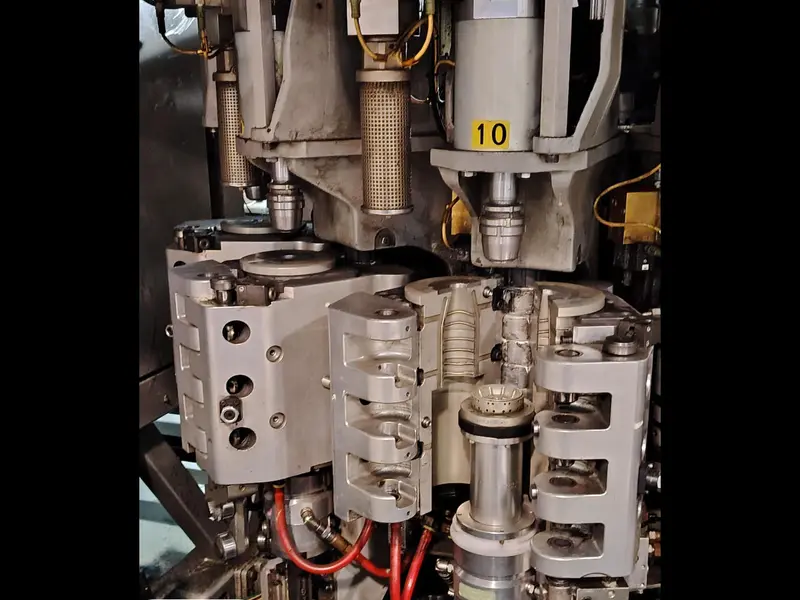

• Transport – heating in good general conditions, we recommend replacing the spindle insertion cam, installing the spindle insertion safety device.

• Spindles in good general condition.

• Load group does not require maintenance. The belt is soaked in oil but does not show obvious wear

• press and toggle are in good general condition, on the compensation plate there is a sign in correspondence of the air supply hole that is not understood if it is a crack, it would seem not.

• planned progress does not highlight particular critical issues, in 2014 they replaced the rack

• ironing in good condition, recommended replacement of gaskets, the rack – pinion to be replaced shows a cracked tooth on the pinion

• blowing system we recommend the replacement of blowing valves and pressure reducer maintenance.

• oven requires cleaning, to be evaluated if necessary replacement lamps (they are expensive as Adphos with NIR technology).

• Bottom movement does not seem to be critical, to check the idling pins with respect to the cams, if the cams are reversed.

• manipulator fluid movements, there are no problems on the pneumatic movements of unpacking and insertion, there are signs on the belt and pulleys without containment, they must be replaced

• pantograph in good condition.

• in-line unloading has been eliminated and replaced by a conveyor belt, to be kept in mind that the exhaust system, presently present in the machine, does not guarantee that the containers remain standing on the belt.