Description

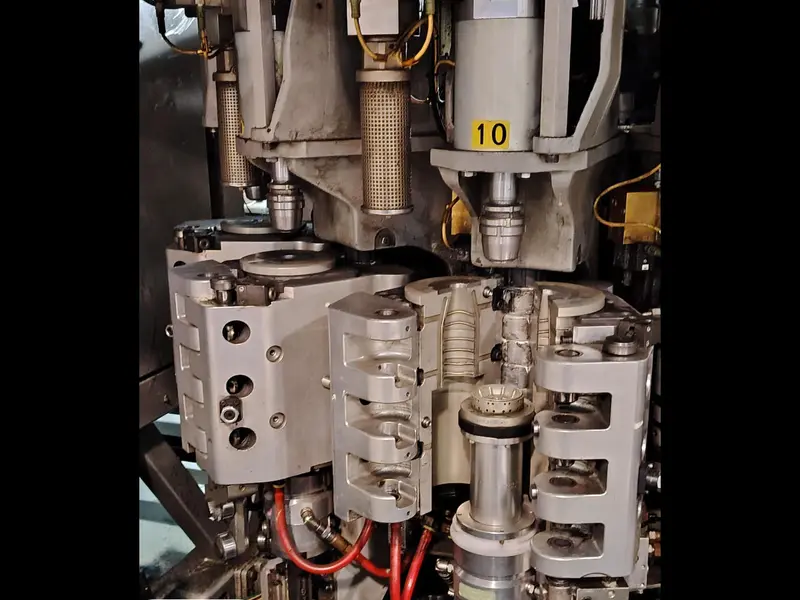

HDPE Used blow molding machine Uniloy MSCK/S/70

In the field of bottling technology, fully understanding the technical specifications of a machine is essential to ensure optimal production. Analyzing the HDPE Used blow molding machine Uniloy MSCK/S/70 model, it is essential to note the rarity of this machinery, designated for the production of HDPE bottles. This material is used specifically to optimize the shelf life of perishable products.

Structural features

With a single track, this HDPE blow molding machine is designed for a concentrated process. The capacity of the blown piece reaches a maximum volume of 5 liters, indicating that it can handle different container sizes. The extruder is the central element for the transformation of material with a diameter of 70 mm and an L/D ratio of 24. Its maximum operating speed stands at 100 rpm. The thermal power of the extruder is 18.1 KW. This power guarantees the correct plasticization of the material before the blowing phase.

Head type and HDPE blow molding machine consumption

The HDPE blow molding machine integrates a single cavity Muller PE 1/120T head. This type of head uses a consumption of 9.67 kW, to optimize and guarantee uniform distribution of the polymer.

The closing system of the applied force is 14,000 kg, therefore this measurement indicates the presenHDPE blow molding machine ce of a very high pressure, exerted to hold the molds in place during blowing. This system is essential to ensure the integrity and uniformity of the container produced. Adequate strength is essential to avoid imperfections or deformations. The machinery has an air consumption that varies between 700 and 1000 Nl/min; allowing a certain operational flexibility. The preform adopted has a standard neck of 30 mm, suitable for processing HDPE.

The HDPE (High-Density Polyethylene) is the primary material used, chosen for its strength and flexibility qualities.

The oil tank has a capacity of 400 liters, a detail that indicates the autonomy of the machinery and its efficiency in terms of lubrication. Considering these specifications, the Uniloy MSCK/S/70 model emerges as an advanced device, designed to meet the technical needs of operators in the sector.