Description

Used shrink wrapper SMI SK 450F up to 28000 bph

Technical Introduction

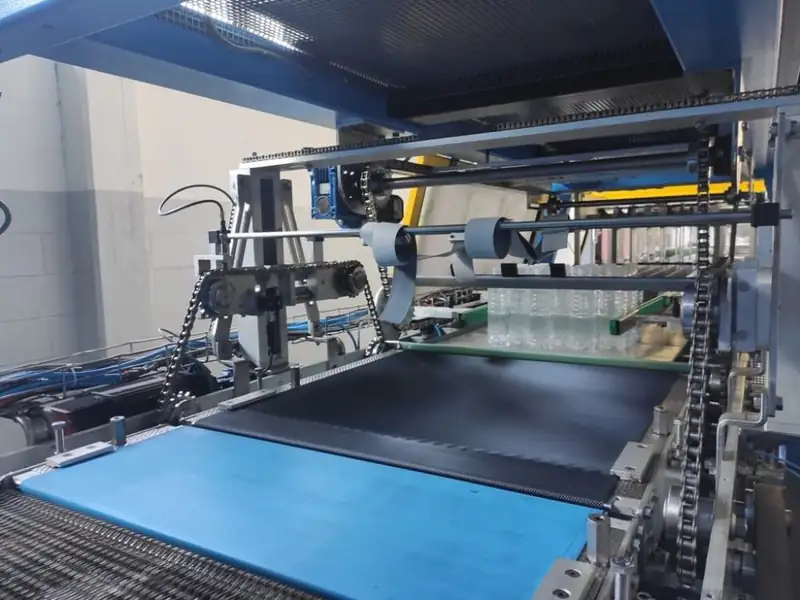

The bottling sector is requiering precise machinery. In fact, the Used shrink wrapper SMI SK 450F up to 28000 BPH presents itself indeed as a leading tool in this category. Made in 2009. The SMI SK 450F represents undoubtedly a synthesis of innovation, efficiency and versatility.

Technical features

The Used shrinkwrapper SMI SK 450F up to 28000 BPH is designed specifically for shrinkwrapping. Without a doubt, it exemplifies a balance between rugged design and advanced functionality. Equipped with durable components, it guarantees a long operating life, minimizing the need for frequent maintenance interventions.

Capacities and Formats of SMI SK 450F

With an impressive operating capacity of 28000 BPH, the Used shrink wrapper SMI SK 450F up to 28000 BPH is ideal for large-scale operations. But it’s not just the ability that sets it apart. The SMI SK 450F is configured to handle a wide range of formats: 4×3 0.33 lt, 3×2 0.33 lt, 4×3 0.50 lt,3×2 1.5 lt, 2×2 1.5 lt, 3×2 1.5lt, 3×2 2lt, and 2×2 2lt. This flexibility makes it suitable for different production lines. This allowes companies to diversify their product range without the need for further investments in new machinery.

Security and Documentation of SMI SK 450F

Safety is certainly a priority in the design of any industrial machinery. The Used shrink wrapper integrates various accident prevention protections. This ensures that operations are conducted in a safe environment. But transparency and ease of maintenance are equally crucial. For this, the machine is supplied with complete technical manuals and a detailed record of the revisions carried out. This not only ensures that the machinery can be kept in the best possible condition but also provides clear traceability of maintenance and overhaul operations.

Operational Status and Materials

The machinery is currently in a state described as “Disassembled and ready for operation”. This indicates that, although it has been used, it has been maintained in such a condition that it can be quickly put back into operation. Another technical aspect to underline is the type of film used. The machine uses a neutral film for heat-shrinking operations, ensuring a high-quality finish and effective protection of the bottled products.

Type of Entry and Operational Flow

The “straight” entry typology is a further example of the engineering precision behind the design of the SK 450F. This configuration optimizes the workflow, minimizing traffic jams and ensuring that the wrapping process occurs without interruptions.

Conclusion

The SMI SK 450F used shrink wrapper model proves to be a high-end technical solution for heat shrink wrapping needs in the bottling industry. With a combination of high capacity, format flexibility, and rigorous security standards, it represents a worthwhile investment for those seeking efficiency and precision.