Description

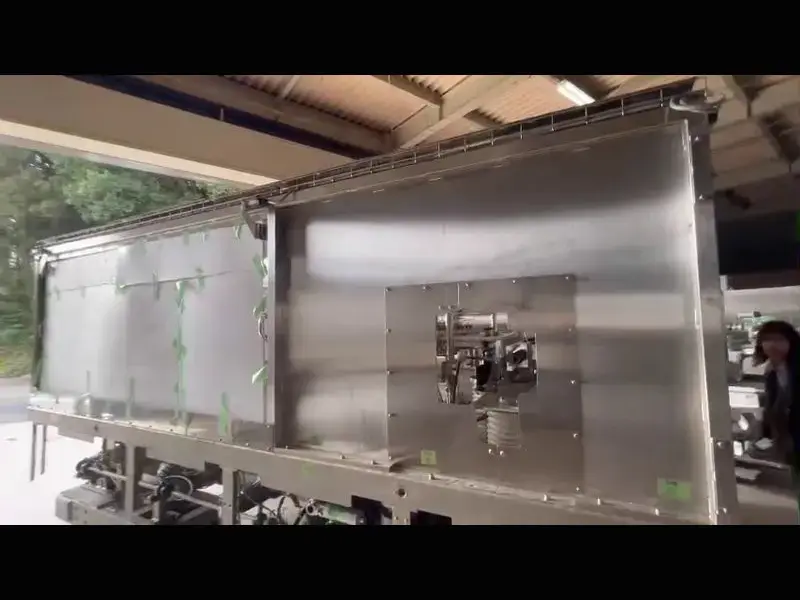

Used Rinsing Machine Enostar SC24 up to 6000 bph

Introduction to the Enostar SC24 Rinsing Machine

The Enostar SC24 rinsing machine delivers a robust and efficient solution for the bottling industry. Furthermore, it operates with a maximum productivity of 6000 bottles per hour. Excelling in managing high production volumes while maintaining high quality standards. Since its introduction in 2003, it has been completely overhauled and never used since then.

Technical Features of the Used Rinsing Machine Enostar SC24

The Enostar SC24 features 24 grips that ensure uniform and precise treatment of each bottle. Additionally, it weighs a total of 2000 kg, providing stability even during intense operations. The use of durable materials and a maintenance-oriented design not only minimizes downtime but also enhances operational efficiency.

Configuration and Performance

The Enostar SC24 measures 1800 mm in width, 1600 mm in depth, and 2000 mm in height, allowing for easy integration into various production layouts. Consequently, it requires a 380V, 60Hz power supply, aligning with widely used industrial standards. Its clockwise rotation optimizes integration with existing production lines, thereby simplifying system implementation without the need for complex structural changes.

Innovation in Bottle Treatment

The Enostar SC24’s mobile nozzle adapts exceptionally to different bottle sizes, ranging from a minimum of 215 mm to a maximum of 365 mm. This adaptability lets it treat a wide range of containers without needing component replacements or adjustments. Similarly, the single water treatment effectively removes residues and contaminants, optimally preparing bottles for the next stages of filling and sealing.

Conclusions of the Used Rinsing Machine Enostar SC24

The Enostar SC24 rinsing machine serves as an excellent solution for those requiring a reliable machine capable of adapting to various production environments. Its productivity up to 6000 bph, combined with a design focused on maximum efficiency and ease of use, makes the Enostar SC24 a wise investment for optimizing bottling processes. Indeed, with these capabilities, the machine continues to stand as an essential tool in the modern bottling industry.