Description

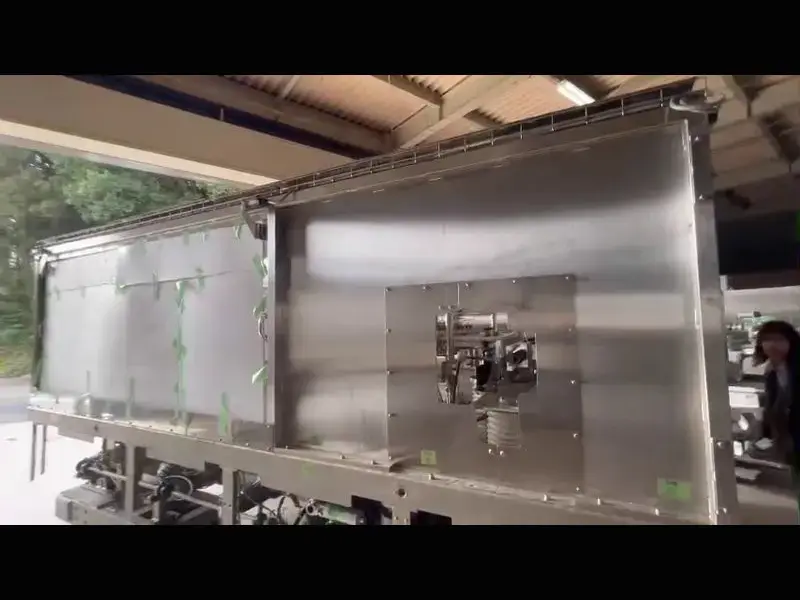

Blowing and Sterilization station MCF Trade Model 2

Never used.

This machine allows the washing of glass containers of various sizes, by means of a jet of air and steam.

Automatic blowing and sanitizing station fast model with sterile air for the elimination of any foreign bodies inside the containers, also prepared for steam injection to sanitize and heat the containers.

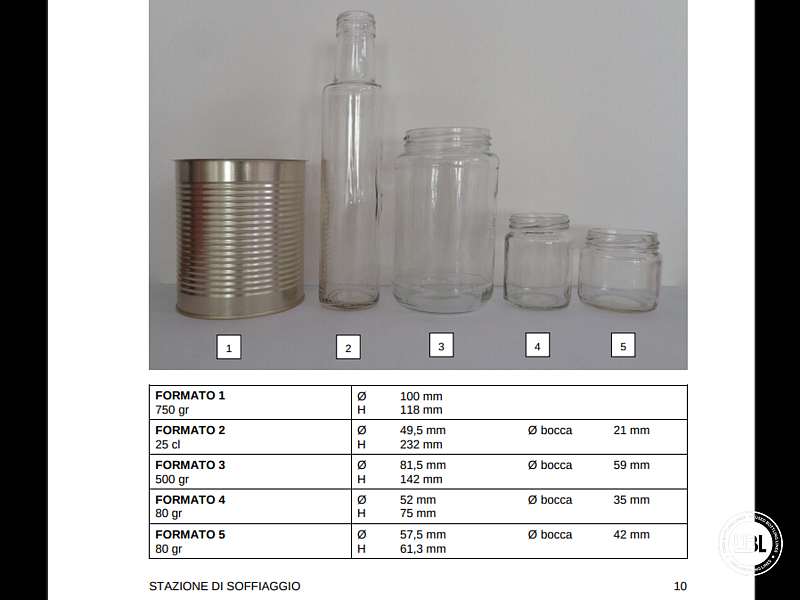

The blowing station is a machine designed for washing glass containers of various sizes (see photo).

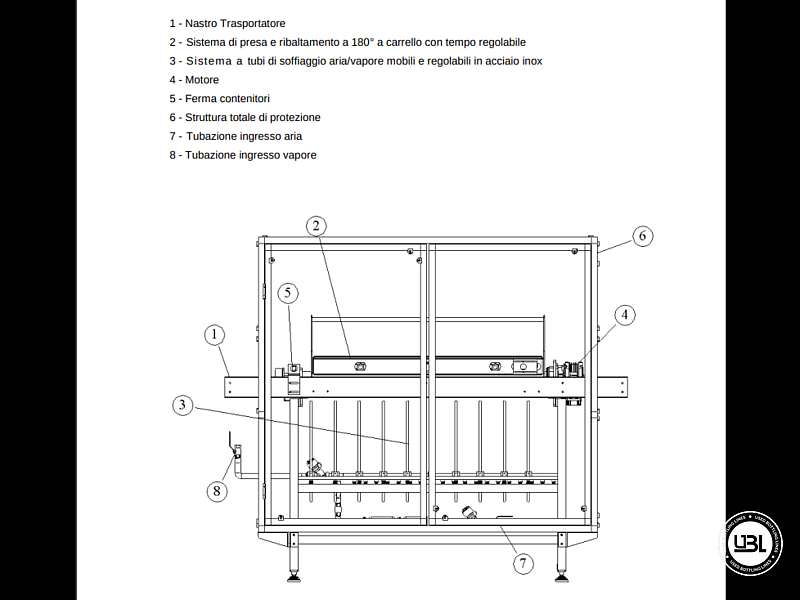

The machine essentially consists of a linear conveyor belt that places the containers on a single row.

These pass through a tilting group formed by a clamping system that can be adjusted according to the format to be processed.

Once the containers are overturned; they descend onto nozzles with adjustable distance and height in order to better center and clean the containers.

At the end of the operation, the containers return to their position on the belt to continue the processing path.

The 180 ° tilting gripping system is designed for containers of various sizes and allows the format change of the containers; to be treated by adjusting the gripping guides only and without changing equipment.

The station, consisting of a structure entirely in stainless steel, is placed on a system of fixed supports with feet to be adjusted once correctly positioned.

The equipment described complies, in all its parts, with the following regulations:

– Council of the European Communities – Directive 89/392 / EEC of 14.06.1989 concerning “THE APPROXIMATION OF THE LEGISLATIONS OF THE MEMBER STATES RELATING TO MACHINES AND SUBSEQUENT AMENDMENTS AND INTEGRATIONS”.- DIRECTIVE 2004/108 / EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15.

December 2004 concerning the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336 / EEC.

– DIRECTIVE 2006/95 / EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 12 December 2006 concerning the approximation of the laws of the Member States relating to electrical equipment intended for use within certain voltage limits.

– LEGISLATIVE DECREE 9 April 2008, n. 81 Implementation of article 1 of the law of 3 August 2007, n. 123, concerning the protection of health and safety in the workplace.

– UNI standards.

– CEI standards.