Description

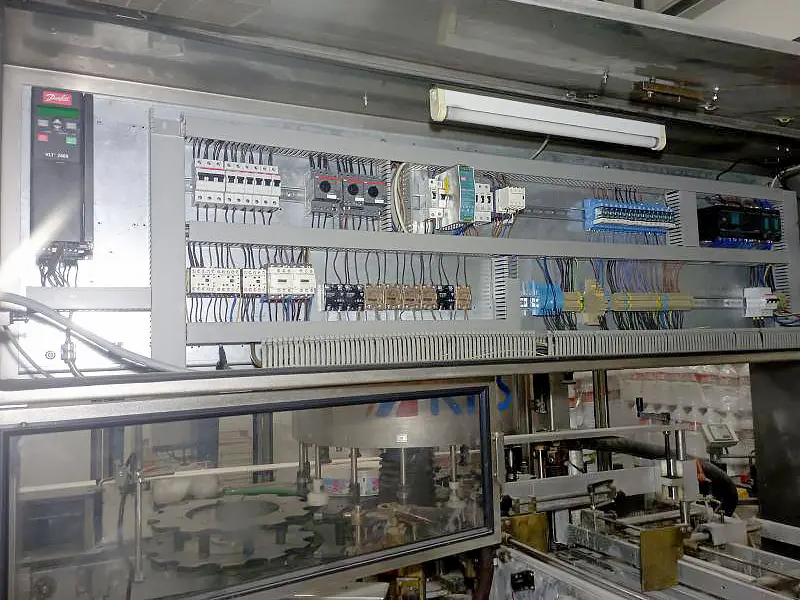

Used Labeling Machine KHS Anker up to 1850 bph

This labeling machine offers an efficient option for bottling production lines. This machine, which KHS manufactured in 2001, delivers high performance with a labeling speed of up to 1850 bottles per hour (bph). Moreover, the machine operates and remains in perfect working condition.

Technical Features of the Used Labeling Machine KHS Anker

Firstly, the used labeling machine KHS Anker up to 1850 bph includes 15 plates and 2 stations, with a counterclockwise rotation direction. Consequently, this design ensures a continuous and smooth workflow, maintaining high production standards. Additionally, the hot glue labeling method provides quick adhesion and a clean finish of the labels.

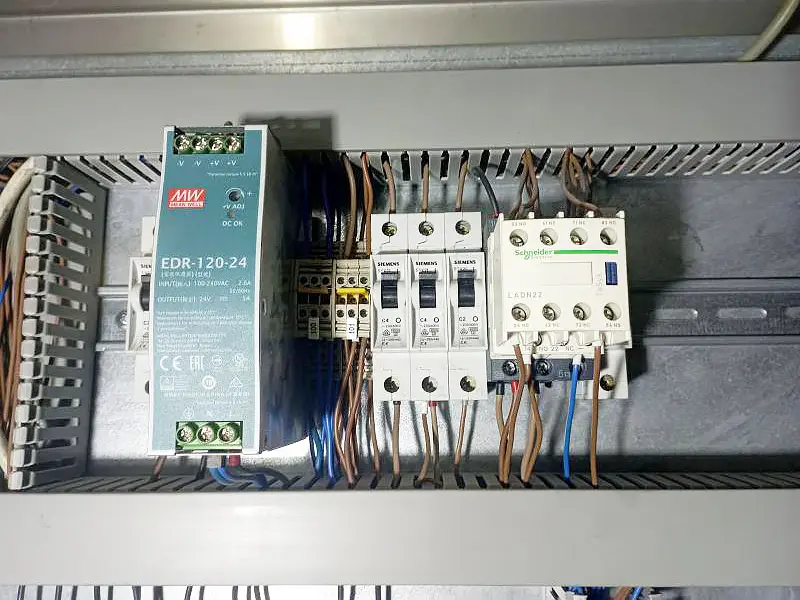

Automatic Adjustments

The KHS Anker up to 1850 bph features automatic glue level adjustment in the rollers. Thus, this system maintains consistent labeling quality, reducing downtime for manual adjustments. Furthermore, the electronically adjustable labeling head ensures superior precision during the process.

Safety and Manuals

The used labeling machine KHS Anker up to 1850 bph includes all necessary safety features, ensuring a safe working environment. Specifically, detailed manuals cover every aspect of operation and maintenance, making it easier for technicians to intervene when needed.

Additional Features

Additionally, the machine provides an additional label smoothing system at the machine exit, ensuring perfect application without air bubbles or wrinkles. The machine measures 3 meters in length, 2.5 meters in height, and 1.8 meters in width, thus requiring adequate installation space in the workspace.

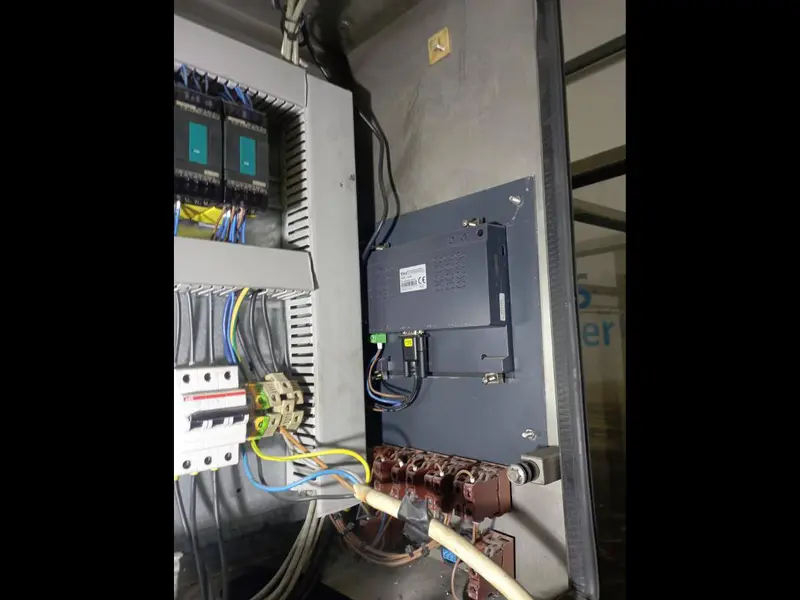

Electrical Specifications

In terms of electrical specifications, the machine includes a voltage of 400V and a frequency of 50Hz. Therefore, this compatibility with standard industrial electrical systems facilitates integration into existing production lines.

Conclusion of the Used Labeling Machine KHS Anker

In conclusion, this machine offers a highly efficient and technologically advanced solution for labeling operations. Its numerous automatic functions, safety features, and available manuals make it an excellent choice for improving productivity and quality in the bottling process.