Pasteurizer

Ref: PST20Related machines

Interested in this machine?

Used flash pasteurizer FH4000 2000L-h

The Used flash pasteurizer FH4000 2000L-h, produced in 2019 by UDMACHINES, represents an advanced heat treatment system used mainly in the bottling industry.

Main features:

The Used flash pasteurizer FH4000, with an operating capacity of 2000L per hour, has been designed to guarantee optimal performance and reliability over time. The ability to reach temperatures of 95°C in a four-stage system is particularly impressive, especially considering the -1 L/h water consumption reduction feature. The overall weight of 2000 kg is a testament to the robustness and durability of the machine, while the integrated safety features ensure safe and regulatory-compliant use.

Technical details:

1) Pasteurizer 1800-2000 lt/h, equipped with control panel, automatic cleaning, alarm detection for unpasteurized product, electronic data system, suitable for egg production.

The temperatures of the pasteurizer can be managed from the control panel, depending on the temperature you would like to put. So, the temperatures that you have already sent me as below:

egg white, 55 celsius-57 Celsius, 1-3 minutes

egg yolk,58 Celsius -63 Celsius, 2.5-4 minutes

whole egg liquid 58 Celsius- 64.4 Celsius , 2,5-5 minutes

Can be controlled as it is convenient for you.

2) Separator connected with the pasteurizer.

You have the possibility to use them together or separately. It has control panel and all the spare parts.

3) Homogenizer connected with the pasteurizer.

You have the possibility to use them together or separately.

It has control panel and all the spare parts.

4) Degaser connected with the pasteurizer.

It is for cleaning the product from the smells.

It has control panel and all the spare parts

5) Chiller connected to the pasteurizer

You have the possibility to use them together or separately.

It has control panel.

Transport and Positioning:

The transport and positioning of the Used flash pasteurizer FH4000 2000L-h is crucial. Although nylon packaging is the standard solution, the possibility of requesting packaging in a wooden crate offers further protection during the shipping and handling phases. The delicate nature of some components requires care when lifting and positioning. Particular care should be given to the adjustment feet, electrical connections, and piping, to avoid potential damage. The optimal placement of the pasteurizer in a workspace also involves consideration of the brightness of the area, guaranteeing safe and efficient working conditions for operators.

Leveling and Alignment:

Correct installation of the Used flash pasteurizer FH4000 2000L-h requires careful leveling. This not only ensures optimal performance of the device but also prevents irregular wear or potential mechanical problems. By using a spirit level, you can ensure that the machine is perfectly horizontal. The absence of the need for anchoring to the floor makes this process less invasive and more flexible.

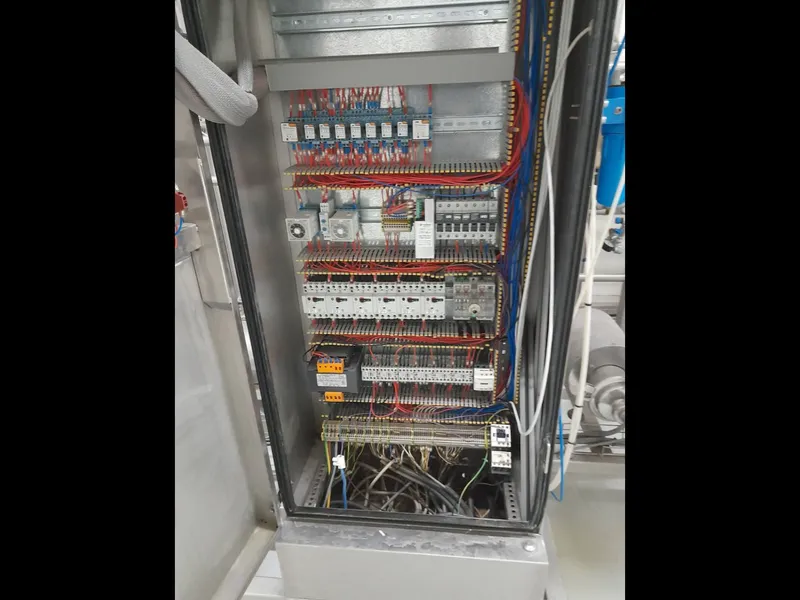

Electric connections:

Safety and efficiency in electrical operations are of primary importance. Before making any connections, it is essential to compare the line voltage with the wiring diagram provided. Every detail, from the choice of power cable to the installation of the thermal-magnetic switch, has direct implications on the performance and safety of the device. The electrical controls, housed in a waterproof panel, are designed to ensure reliable operation over time.

Hydraulic Connections:

The FH4000 pasteurizer has a series of specialized hydraulic connections. These have been designed to handle various operations, from the inlet of hot water and steam to the handling of fluids such as raw and pasteurized milk. Resistance to various pressures and temperatures ensures flexibility and durability.

General information:

Attention to detail is evident in the overall design of the FH4000 pasteurizer. Designed to operate at 380V, with other voltages available on request, this appliance is adaptable to different operational needs. Safety features, including an emergency button and safety switches, have been integrated to ensure operator protection in all circumstances.

Finally, regular maintenance and proper lubrication are essential to maintaining the efficiency and longevity of the device.