Used Ackey SEA 6 Filter up to 12000 lt/h

Introduction to Filtration Technology of the Ackey Filter SEA 6

In the industrial bottling sector, firstly, choosing the right filtration system is crucial. It ensures the final product’s quality and purity. The Used Ackey SEA 6 Filter it’s a high-level microfiltration option, capable of processing up to 12000 liters per hour. Consequently, this makes it an efficient and effective solution for filtration needs.

Technical Specifications and Capacity

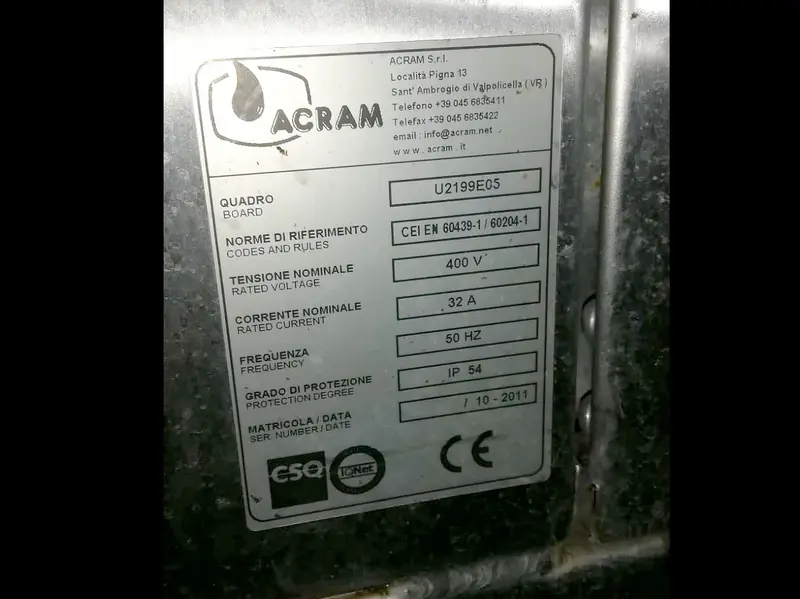

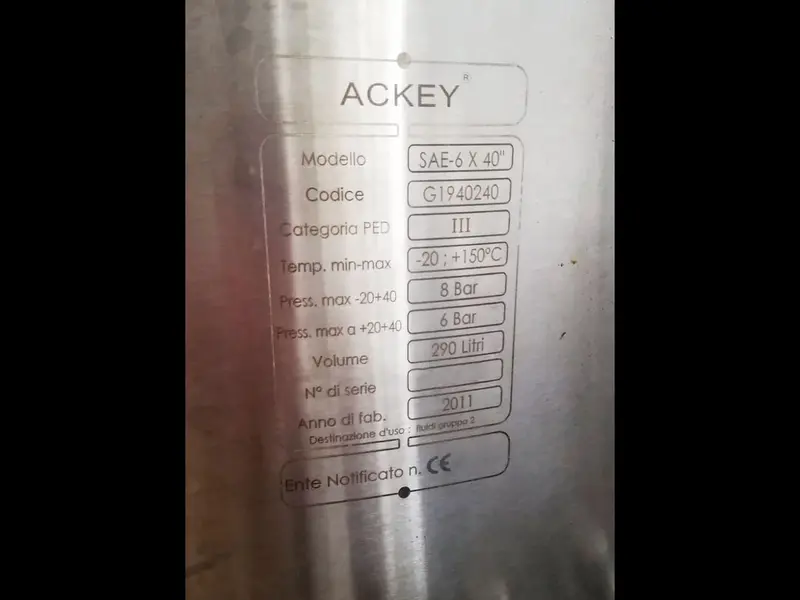

Currently in storage, the Ackey SEA 6 was produced in 2011 by the renowned manufacturer Ackey. Specifically, this model, SAE 6 X 40, is notable for its filtration speed, reaching 12000 L/h. Hence, it proves to be an excellent choice for facilities requiring high processing volumes without compromising quality.

Advanced Filtration Technology

Regarding technical details, the system reveals that the filter type used is a housing for microfiltering. This technology is especially suited for deep cleaning of liquids, for instance, for wine or water filtration applications. Its current condition is listed as in storage, indicating the system is ready for immediate installation and use without the need for preliminary interventions.

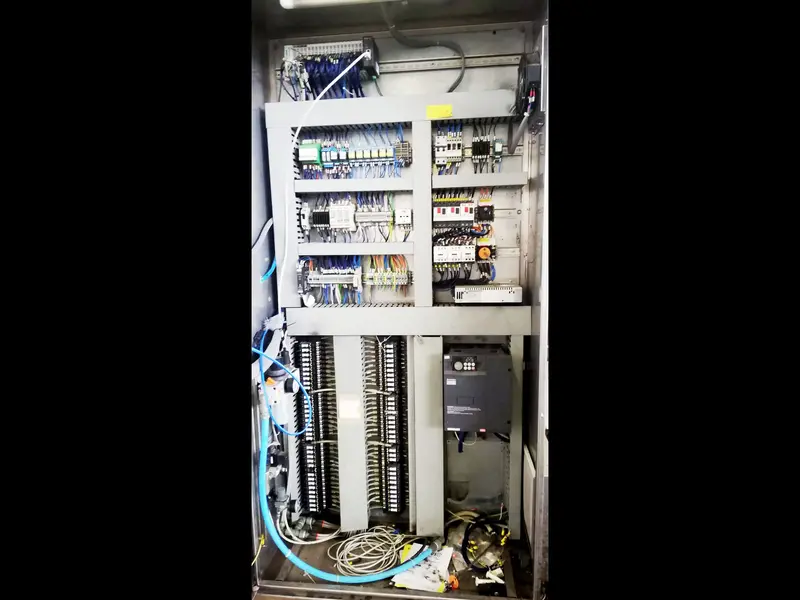

Configuration and Automation

Digging deeper, importantly, the SAE microfiltration plant is fully automatic, a feature that enhances operational efficiency and reduces the need for manual interventions. The setup includes, notably, two bells for wine microfiltration, each equipped with 18 candles of 30 inches, and two water microfiltration bells, each with 6 candles of 40 inches. This arrangement allows for remarkable versatility, making the Ackey SEA 6 filter suitable for various types of liquids.

Maintenance and Installation of the Ackey Filter SEA 6

A crucial aspect of the system, moreover, is the stainless steel tank for storing water used in washing cycles. This ensures that the system maintains high filtration quality over time. Additionally, valve management for product and washing operations is automated through a PLC, further simplifying the plant’s operation and ensuring efficient maintenance.

Conclusion: Efficiency and Productivity

Finally, the entire system is installed on a stainless steel platform. This not only provides a solid and durable base but also facilitates the plant’s integration into various production environments. The hourly capacity of about 12000 lt further highlights its high productivity, in line with the needs of large-scale facilities.