Filling Machine

Ref: R66Related machines

Interested in this machine?

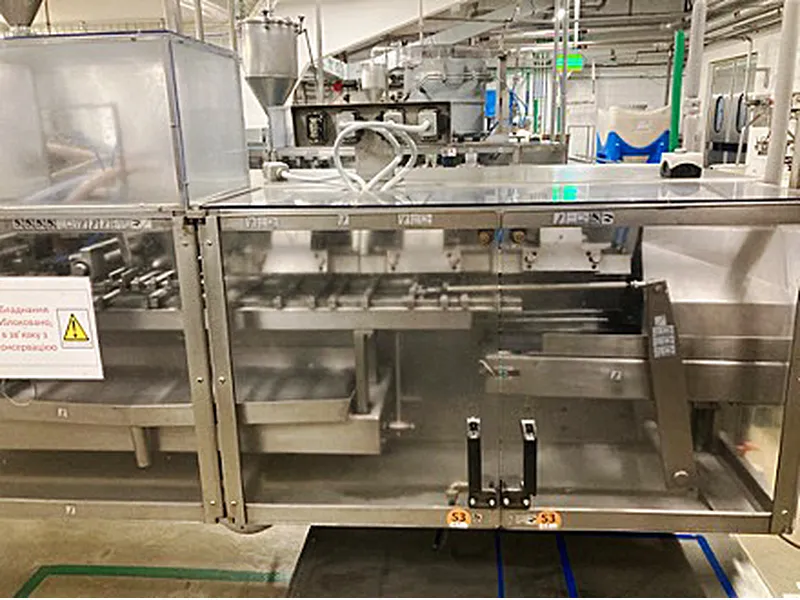

Used doy pack filling machine Bossar B 2500

Introduction and Structural Composition

In the landscape of technical solutions for packaging, the used Bossar B 2500 doy pack filling machine emerges as an advanced piece of equipment, thanks to its construction features and high-level functionality. Starting from its configuration, the Bossar B 2500 is a horizontal machine, specifically the B2500 L/STU-1 model. This designation is not accidental but indicates its ability to operate with a horizontal arrangement, fundamental for certain types of packaging and to maintain consistent production efficiency. This filling line works in various formats, from 200ml to 1l.

A crucial part of its architecture is the choice of stainless steel for the entire base of the automatic machine. This not only provides significant corrosion resistance but also a rigid and robust structure, which is indispensable in an industrial environment where equipment durability and resistance to various mechanical stresses are essential.

Sensing Technology and Power System of Used Doy Pack Filling Machine Bossar B 2500:

The Used doy pack filling machine Bossar B 2500 integrates an advanced sensing system, the photo sensor, which plays a vital role in ensuring precision during the filling process. Its function is to verify the correct position of the packaging material, preventing errors that could lead to waste or production defects. This technology represents a qualitative leap compared to traditional methods, offering greater operational reliability.

In tandem with the sensor, we find the exit conveyor belt. This component is no less important, as it manages the flow of consumables through the machine, ensuring that there are no interruptions or malfunctions that could compromise the entire production cycle. Its presence is further testimony to the technical sophistication of the Bossar B 2500.

Versatile Dosing Systems and Applications

Continuing the examination, we reach the heart of the filling process: the dosing system. This system, in particular the piston dispenser, is calibrated to deliver a precise volume of product in each cycle. This ensures consistency of dosage and integrity of the final product. The dispensing nozzles are specific to liquid products, while the nozzle tips are designed to handle paste products, underlining the machine’s ability to handle a variety of materials.

Film edge correction is another technical feature that distinguishes this equipment. This functionality is essential to maintain the correct tension and alignment of the packaging film throughout the entire process. The reason is to prevent damage and anomalies.

Conclusion and Final Considerations

The Used doy pack filling machine Bossar B 2500 is not just an assembly of mechanical components. It’s the result of years of innovation in the field of doy pack filling machines. It is important to note that Bossar, the original manufacturer of this line, was recently acquired by another company called SIG. However, this does not affect the performance or reliability of the system. This is because the machine maintains its technical specifications and continues to represent excellence in its field.

By choosing the used Bossar B 2500 doy pack filling machine, industry operators ensure an optimized and high-quality production process. This is possible with a machine that symbolizes the pinnacle of bottling and packaging technology.