Description

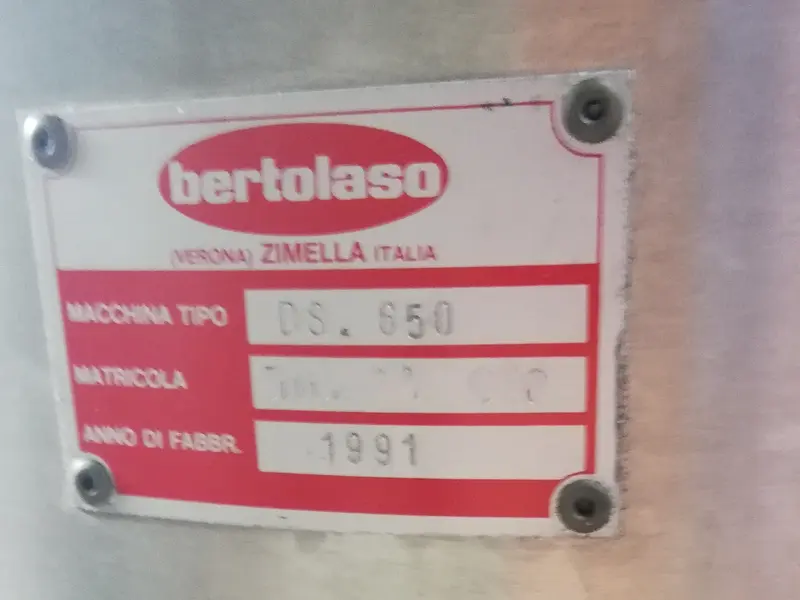

Used Capping Machine BERTOLASO up to 4500 bph

Technical Analysis of the BERTOLASO Capping Machine

The BERTOLASO SIGMA 103 model exemplifies capping technology that significantly enhances high-speed bottling processes. Originally designed in 1983, this machine delivers a production capacity of up to 4500 bottles per hour (bph), thus showcasing its effectiveness in intensive industrial settings. Importantly, its long operational life and minimal maintenance requirements solidify its market value among used capping machines.

Operational Details and Functionality

Equipped with three capping heads, the SIGMA 103 allows for precise application of plastic press-on caps. Furthermore, its clockwise rotation direction facilitates seamless interactions with bottling line components, consequently promoting a continuous and uninterrupted workflow. This specification not only boosts productivity but also critically minimizes the risk of operational errors, which is essential in environments that demand speed and precision.

Electrical Parameters and Maintenance Considerations

Operating at a voltage of 380 V and a frequency of 50 Hz, the machine’s electrical setup matches typical European industrial operations. Currently stored in a warehouse, it must undergo a detailed inspection to verify the integrity of its electrical and mechanical components. Additionally, this step is critical to ensuring the machine can resume production without compromising the quality of the capping process.

Conclusions

In conclusion, the BERTOLASO SIGMA 103 capping machine stands as a high-value technological resource for the bottling industry. With its high production capacity and efficient capping heads, it is ideally suited for integration into a modern bottling line, ensuring high performance and cost-effective operations. Moreover, this analysis emphasizes the necessity of thoroughly assessing the machine’s operational conditions before deployment to maximize efficiency and extend its lifespan.