Categories

Used Bottling Machinery Types

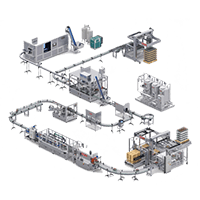

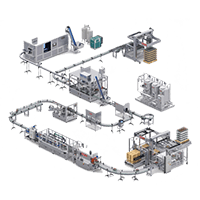

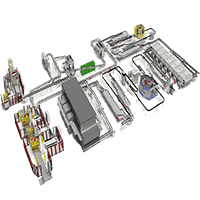

Used Complete Bottling Lines

Complete PET Line

A complete PET line includes all the machinery for the production with PET containers for filling products such as water, juices, carbonated drinks, detergents, vinegar and more. From the blow molding machine to the palletizer.

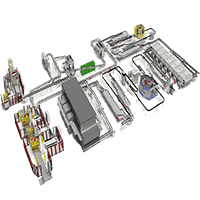

Complete Glass Line

A complete glass line includes all the machinery for the production with glass containers for filling products such as wine, beer, oil, carbonated drinks, spirits and more. From the depalletizer to the palletizer.

Complete Cans Line

A complete cans line includes all the machinery for the production with cans containers for filling products such as beer, carbonated drinks, tea and more. From the depalletizer, syrup room, seamer to the palletizer.

Complete Brik Line

A complete brik line includes all the machinery for the production with carton containers for filling products such as milk, juice, dairy products, yogurt, wine and more. Usually aseptic. From the filling machine to the palletizer.

Used Main Filling / Processing Equipment

Blow Molding Machine

The first step is the blow molder, which heats up the preforms and, with the help of special molds, proceeds to blow them up utilizing high pressure air to form a plastic bottle. At the end of the process the bottles are ready to be filled.

Cap Unscrewer

The cap unscrewer takes care of removing the caps still present on the glass bottles that have returned to the factory after being used. It is generally used before the bottle washer.

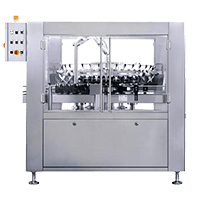

Capping Machine

The capper is usually placed after the filler, it is used to close bottles, cartons, etc. after the filling phase. The caps can be made of different materials such as metal, plastic, cork or synthetics.

Capsuling Monoblock

The capsuling monoblock places a PVC or polylaminated heat-shrinkable aluminum capsule on the glass bottle after it has been capped.

Filling Machine

The filler is considered the heart of a filling line. It puts the product inside the container. It can also be isobaric (characterized by constant or equal pressure), depending on whether the product must be still or carbonated.

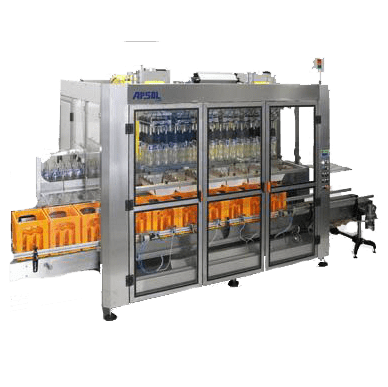

Filling Monoblock

The filling monoblock combines the filler as well as additional machines in a single block, e.g. a rinsing machine or a capper but frequently also a blowing machine and a labeler.

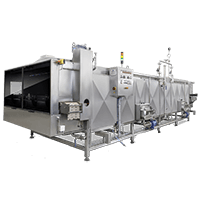

Heating / Cooling Tunnel

The heating / cooling tunnel brings the bottled product to room temperature, after it has been filled hot or cold.

Inspector

The inspector is an indispensable part of a bottling line. It inspects everything that would be impossible to see with the naked eye at high speeds, like the bottle itself, the level of product inside, the cap, or any anomaly.

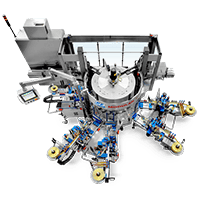

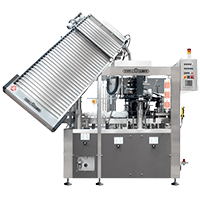

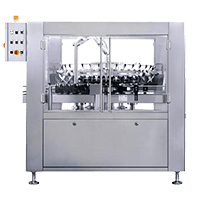

Labeling Machine

The labeler enables you to create brand recognition to your containers, in a way, your business card. It applies the labels to the bottles and if necessary it also affixes the state seal.

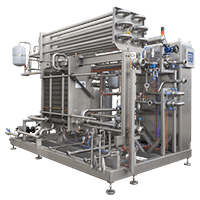

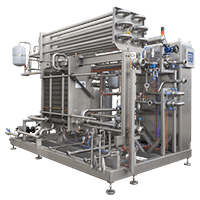

Pasteurizer

The pasteurizer is used to sanitize and extend the shelf life of beverages such as milk and dairy products, juices and often wine and beer. It eliminates the pathogens present in the product without altering the taste.

PET Preforms Injection

The preform injection system allows you to create PET preforms. It uses polymers, which after being dried, are processed and transformed into preforms using molding to then be transported much more efficiently than a whole bottle.

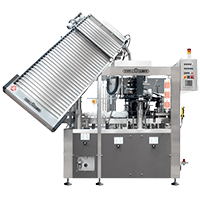

Rinsing Machine

The rinsing machine washes the bottle internally to remove any residues which ended up accidentally inside. The machine can do multiple treatments based on sterilization needs.

Saturator / Carbonator

The saturator is a machine used for the preparation of carbonated drinks through the introductionof carbon dioxide.

Syrup room

The syrup room is a set of machines that mix, pasteurize, sterilize particular types of flat, carbonated or tea drinks. Usually sweetened beverage. Inside there are premixes, pasteurizers, mixers, preparers, CIP. According to the variants.

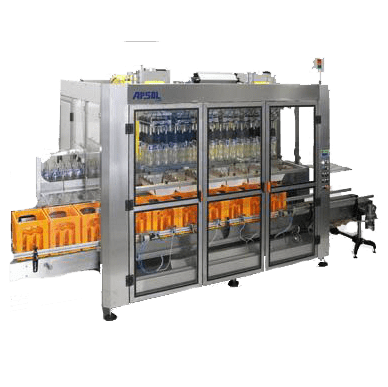

Bottle Washing Machine

The bottle washer can sterilize the bottles through various chemical baths that remove foreign bodies, residues, labels, etc.

Bottle Washer Dryer

The washer dryer for bottles allows the washing and the complete drying of the outside of the filled bottle, to enable perfect labeling and packing without residual humidity.

Wirehooder

The wirehooder places a wirehood on the bottle immediately after capping, exclusively on mushroom cork caps for spumante.

Packing / End of Line

Case Erector

The case erector forms a cardboard box from a flat box. It takes the box from the storage, folds it and seals the lower part with adhesive tape.

Case Packer

The case packer inserts the container, for example the bottle, filled, capped and labeled inside the carton box.

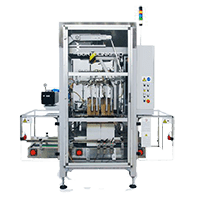

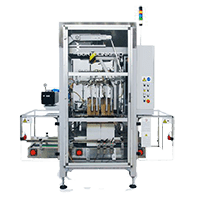

Case Sealer

The case sealer closes the cardboard box with the bottles inside, placing adhesive tape on the top of the box. Ready to be stored.

Crater

The crater is used to place the bottles in crates. Its operation is similar to the case packer.

Depalletizer

The depalletizer has the function of removing the bottles from the pallet layer by layer and place them on the line to be worked.

Partition Inserter

The partition inserter places vertical sheets of cardboard inside the box to create the hives that protect the glass bottles inside the box, dividing them one from the other.

Handle Applicator

The handle applicator attaches a plastic handle to the bundles through welding, to facilitate the manual transport from the shop for the end user.

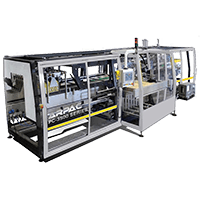

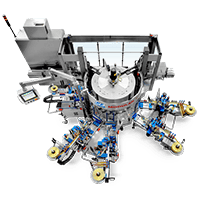

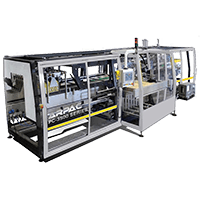

Packing Monoblock

The packing monoblock, like the filling monoblock, combines several machines, and performs the whole packing process, including the erection of the cardboard box, the insertion of the containers inside the boxes and the closure.

Pallet Stretch Wrapper

The pallet stretch wrapper is one of the last machines of a complete bottling line. Through various systems it wraps the entire pallet. From here the pallet can be stored or loaded directly onto the truck

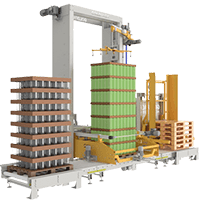

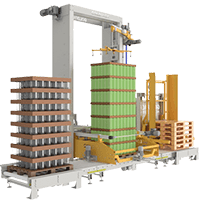

Palletizer

The palletizer is a machine that arranges and stacks boxes or bundles precisely, in layers on a pallet. There are various types, by push, with robotic arm. Afterwards from the palletizer, the boxes pass to the pallet wrapper.

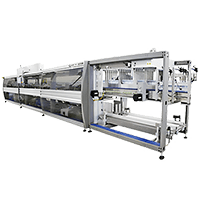

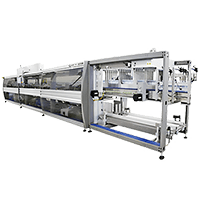

Shrink Wrapper

The shrink wrapper groups cans and bottles in various formats, closing them with a shrink-wrapping film.

Wrap Around Packer

The wrap around similar to the packing monoblock encloses the bottles inside a box. But instead of putting them in a box already made, it builds the box around the bottles.

Other Bottling Equipment

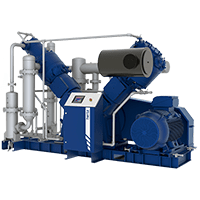

Compressors

The compressor allows the operation of almost all the machines in a bottling line. There are generally two types, high and low pressure depending on the type of machinery connected to it.

Osmotizer

Osmosis systems include all systems which purify, demineralize and decalcify water.

Printer / Coder / Marker

Printers can be of different types and can have different functions. They can print on bottles, pallets, boxes, labels. Based on the needs of the production line.

Tanks

Tanks are used in the storage of beverages such as wine, fruit juices, milk etc. They help conserve products before being bottled, sometimes even refrigerating them for better preservation.

Go to All Machines