Description

Used UHT Milk Preparation Room Tetra Pak 4000 L-h

Operating Capacity and Product Versatility

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers optimized aseptic thermal processing for dairy and beverage applications. Specifically, the unit operates at variable flow rates from 2000 to 4000 liters per hour, making it suitable for plain milk, flavored milk, drinking yoghurt, and condensed milk. Furthermore, with program adjustments, the same line also processes fruit juices, nectars, and soft drinks. As a result, this flexibility makes it ideal for multi-product operations. The plant currently remains in storage, and as such, is ready for relocation and installation in a new production facility.

In-Line Aseptic Homogenization

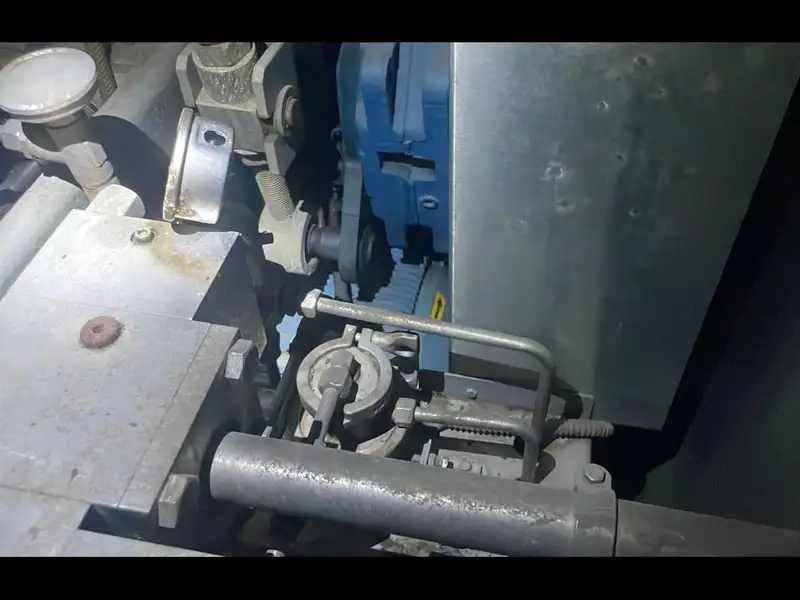

The Used UHT Milk Preparation Room Tetra Pak 4000 L-h includes an aseptic homogenizer manufactured by Tetra Pak, model Tetra Alex, year 2006. In particular, this unit, positioned downstream of preheating, operates in sterile conditions to ensure the breakdown of fat globules and uniform dispersion of solid and liquid phases. Consequently, it helps preserve the emulsion stability of flavored milk and yoghurt drinks. Moreover, the inline aseptic design reduces contamination risk after thermal processing. Therefore, it maintains the product’s physical and chemical consistency throughout downstream stages. In addition, the robust construction simplifies cleaning and routine maintenance.

Clean-in-Place (CIP) System

The line integrates a CIP (Clean-in-Place) system supplied by Gemak in 2009, which consists of four dedicated tanks: nitric acid, caustic soda, hot water, and rinse water. Notably, the system automatically sanitizes all product-contact surfaces under controlled parameters. In doing so, it ensures compliance with hygiene standards across multiple cleaning phases. Additionally, it manages solution recovery and water usage optimization across all cleaning circuits. As such, the CIP system in the Used UHT Milk Preparation Room Tetra Pak 4000 L-h minimizes downtime and supports continuous production. Above all, it protects product integrity between production cycles.

Thermal Treatment and Holding Time Control

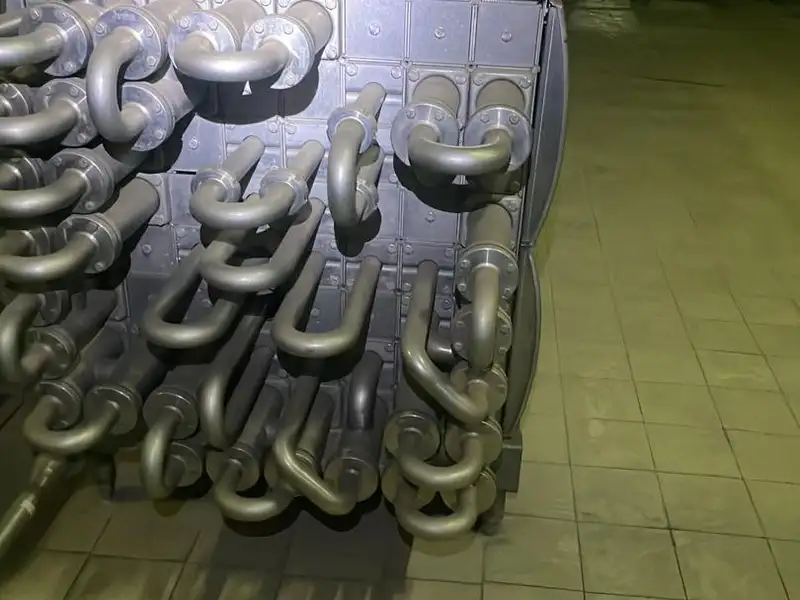

The sterilization process relies on a holding coil supplied by Tetra Pak in 2006, designed to maintain the product at the target temperature for the required time. When paired with a tubular UHT heat exchanger, this coil enables indirect and uniform thermal processing. Thus, the system ensures accurate residence times and optimal microbial reduction. Likewise, the unit maintains organoleptic properties through consistent thermal transfer. Therefore, the Used UHT Milk Preparation Room Tetra Pak 4000 L-h delivers reliable processing for both dairy and plant-based applications.

Deaeration and Sterile Storage

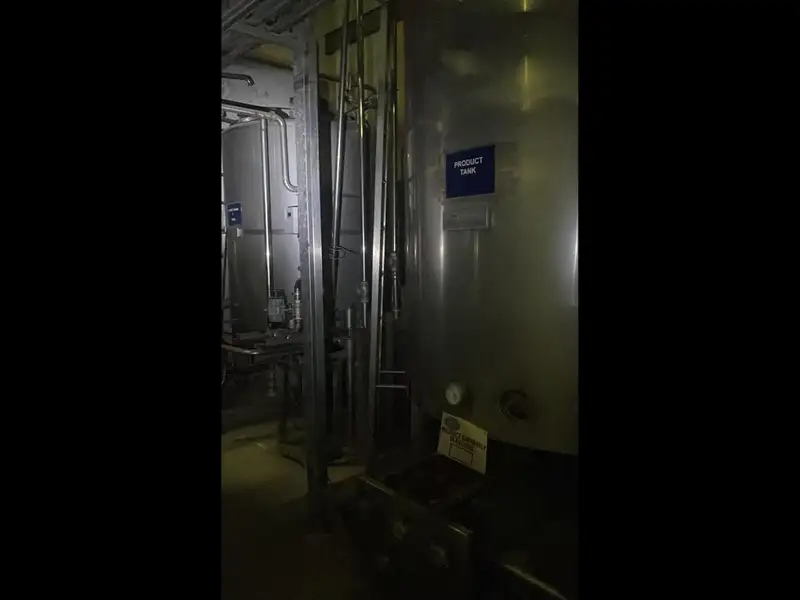

The system includes a Tetra Pak deaerator from 2006, which removes dissolved oxygen and unwanted gases before the UHT process. Accordingly, it improves product shelf-life and minimizes oxidative degradation. Furthermore, the deaerator connects directly to a 3500-liter sterile tank, model Alsafe, also by Tetra Pak (2006). Because of this connection, the product transfers in a closed, sterile environment. In turn, this configuration preserves product sterility after treatment and maintains aseptic conditions up to the filling stage.

Technical Conclusion

In summary, the Used UHT Milk Preparation Room Tetra Pak 4000 L-h offers a comprehensive solution for aseptic preparation of dairy and beverage products. Thanks to its modular layout and integration of top-tier components, the line supports high-efficiency operations. Whether the application involves milk, yoghurt, or juice, this system ensures safe and reproducible results. Finally, with all critical systems in storage and ready to ship, the line is available for rapid commissioning in modern processing environments.