Description

Used Tetra Pak complete bottling line up to 9000 bph

General characteristics

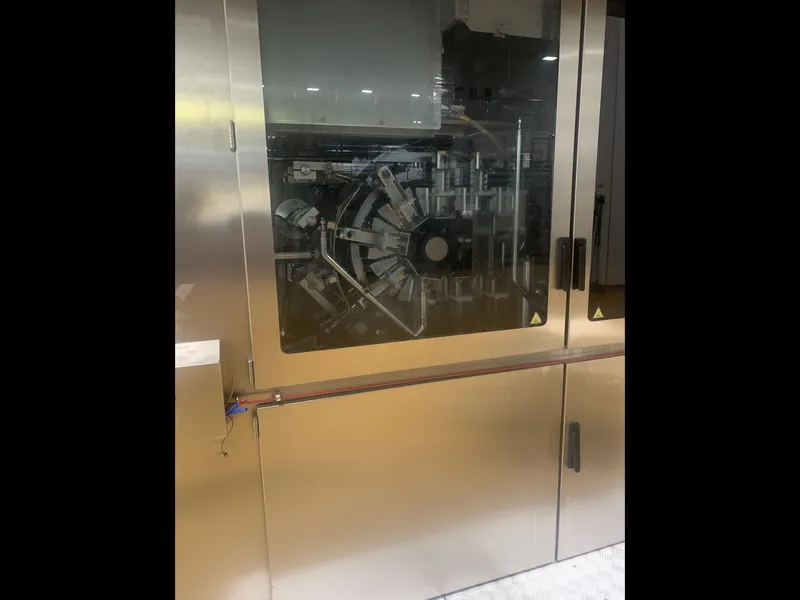

The used Tetra Pak bottling line, with a capacity of 9000 bottles per hour, has a configuration that responds to different production needs. Founded in 2004, this line has accumulated 18,220 hours of work, a testament to its durability and reliability. The backbone of the system is the TT3 180v XH OSO filling machine, capable of handling TETRA TOP formats, thus providing versatility without compromising operational efficiency.

Packaging

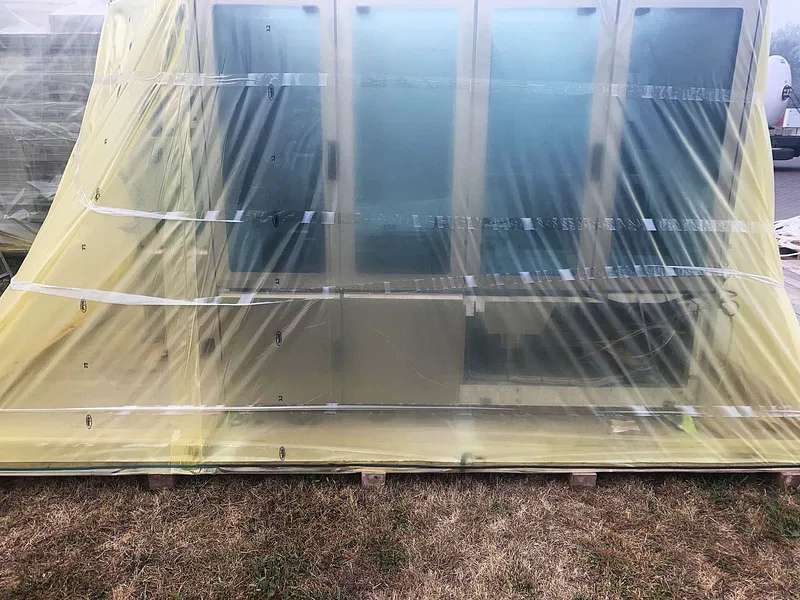

The TCBP70 cardboard packaging machines, both 110v with 8516 working hours and 100v with 12770 working hours, support different packaging configurations, in 2×4 and 3×6 formats respectively, adopting the Wrap Around technique for maximum protection during distribution.

Additional components of the Used Tetra Pak line

The inclusion of a granulate container (GS) and a conveyor lubrication unit (CLU-20) indicates a design attentive to maintenance and operational efficiency. These components are essential to maintain optimal performance and extend the life of the line.

Capacities and Configurations

The used line can handle a range of formats ranging from the smallest 250ml bottles up to 1000ml ones, thus offering great adaptability to market needs. The configuration of the line can be modulated according to production needs, TETRA TOP batches.

Final Considerations

This detailed analysis of the used Tetra Pak bottling line with a capacity of 9000 bph offers a complete picture of the capabilities and technical considerations for industry experts, providing all the information necessary for a possible integration or improvement of their production lines.

This equipment produces simultaneously both formats 250ml and 1000ml, as shown in the video