Description

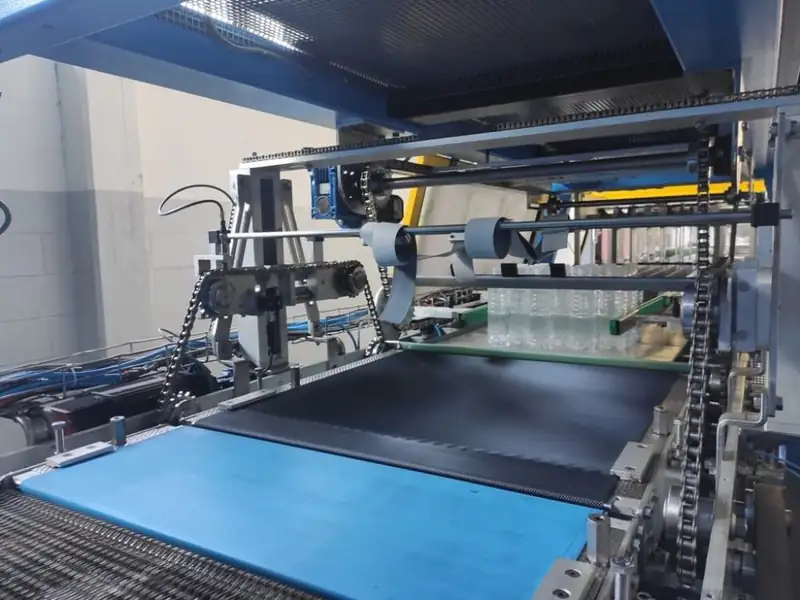

Used Shrink Wrapper GIEMME model VEGA VE 20R91R – year 2016

Vega lines work with centering of the print on the bundle with even higher performance and speed.

These lines include the latest mechanics, new generation PLCs, wide flexibility of use as well as rapid and precise format change. It has the possibility of packaging products of small or medium dimensions on double or triple tracks.

Suitable for a wide variety of product types, whether made from glass, plastic, cardboard or metal.

Some technical specifications:

To meet the various requirements the following have been created for the machine:

Channeling units for rectangular or square shaped products box overlay feeders, bundle overlay clusters, conveyor belts and roller conveyors on the exit of the bundler.

The main purpose of this type of machinery is to make the multipack, this corresponds to packs of 6 bottles closed in a cardboard and then gathered in a bundle of 4 packs.

Multipack format is widely used by companies because it guarantees the consumer the protection of the bottles. The entrance of the machine can be straight or at 90 degrees with respect to the main driving axis of the cartons. This type of input can depend both on the layout of the production line or on the speed of the bundler.