Description

Used Seaming Machine up to 80,000 Cans/Hour

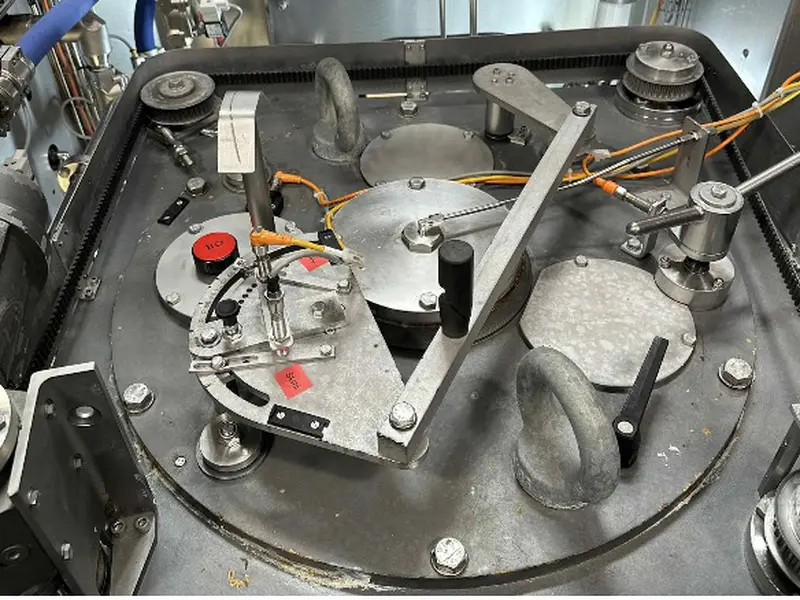

Ferrum, the Swiss manufacturer, built the FERRUM F812-1 seaming machine in 2005. Since then, the owners have dismantled this machinery, which specializes in bottling beverages in cans, and currently offer it for personal inspection in the warehouse. The FERRUM F812-1 not only offers high performance but also integrates easily into existing production lines.

Technical Details of the Ferrum Seamer

To begin with, the FERRUM F812-1 features 12 seaming stations, allowing a production capacity ranging from 70,000 to 80,000 cans per hour. Furthermore, the machine uses can ends and lids type 202, which is standard in the beverage industry. It includes an electric height adjustment system with integrated measurement and display; thus, it facilitates adaptation to different can sizes.

Mechanical Specifications of the Ferrum Seamer

In terms of mechanical specifications, the chain pitch measures 92 mm, and the minimum height of the can conveyor belt level is 1,100 mm. Moreover, weighing a total of 4,800 kg, the FERRUM F812-1 ensures stability and robustness during high-speed operations. Consequently, these technical characteristics make the machine suitable to meet the most stringent production demands.

Condition and Availability

The FERRUM F812-1 remained in production until the end of 2023, ensuring that the machinery is up-to-date and in excellent operating condition. Additionally, because the machine is available for direct inspection, technicians and industry experts can personally assess its efficiency and reliability. This opportunity allows them to verify the machinery’s compatibility with specific production requirements.

Final Considerations about the Used Seaming machine up to 80000 cph

For companies needing to increase production capacity or upgrade their bottling lines, the FERRUM F812-1 represents a high-level technical solution. Therefore, thanks to its performance and advanced features, it can significantly contribute to the efficiency and quality of the production process.