Description

Used Robot Palletizer FANUC 10800 bph

General Description of the Robot

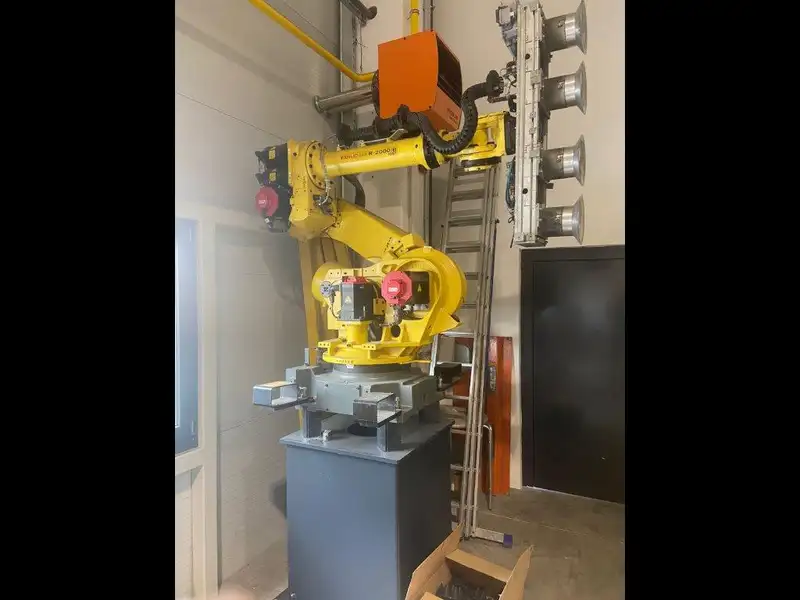

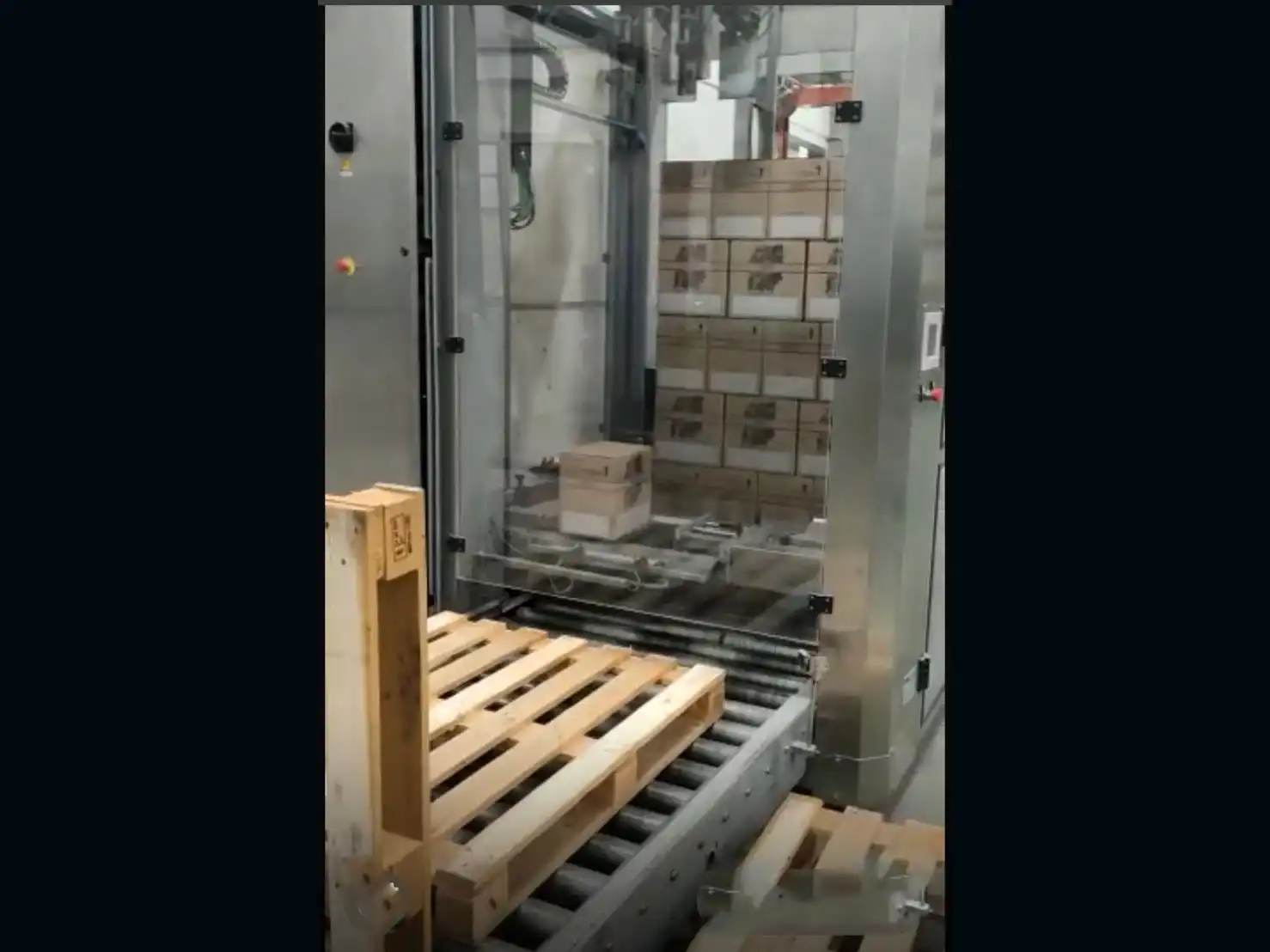

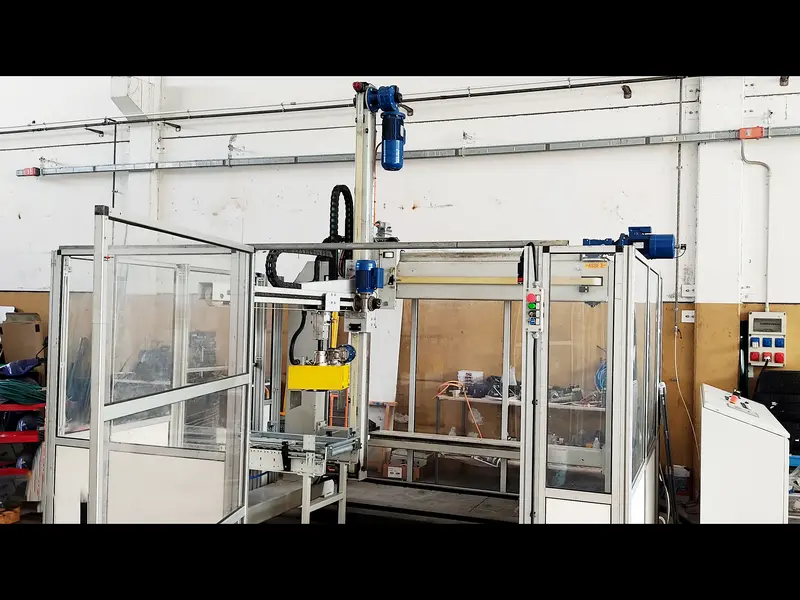

The Used Robot Palletizer FANUC 10800 bph is a high-performance industrial robotic unit specifically designed for automated palletizing operations in bottling plants. The configuration combines the FANUC R-2000iC/165F robot and the R-30iB Plus controller. As a result, the system ensures excellent reliability, mechanical robustness, and positioning accuracy in high-intensity production environments.

Operational Capacity and Mechanical Configuration

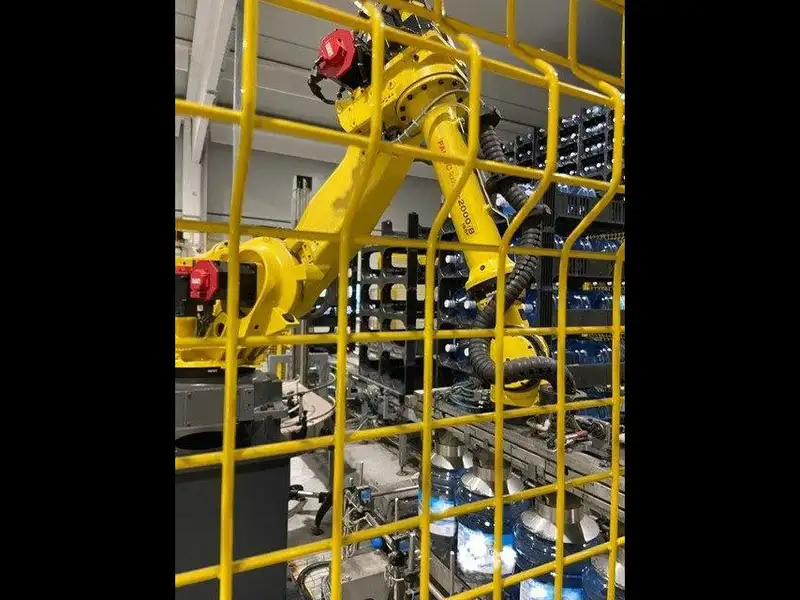

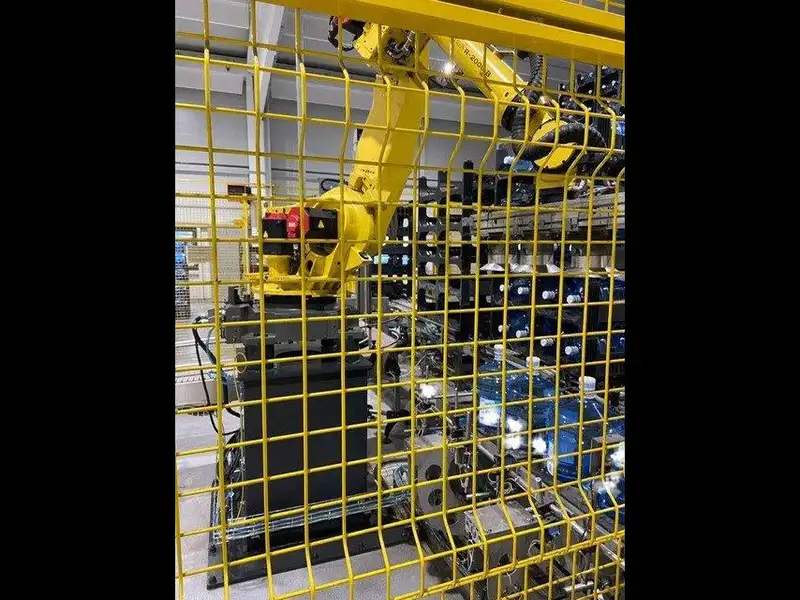

Equipped with a six-axis articulated arm, the Used Robot Palletizer FANUC 10800 bph delivers ±0.05 mm repeatability, in full compliance with ISO 9283 standards. Furthermore, it achieves a maximum reach of 2655 mm and supports payloads of up to 165 kg at the wrist. Thanks to its rotating arm design, the system executes palletizing cycles with high precision. In particular, it grips containers by the neck using pneumatic grippers, thereby minimizing instability and maximizing throughput.

The machine reaches a production speed of 10,800 bottles per hour on the 2×6 format, making it ideal for high-efficiency bottling lines.

Previous Applications and Current Condition

Previously, the Used Robot Palletizer FANUC 10800 bph operated in a water bottling plant, where it consistently palletized 19-liter bottles. Currently, the robot remains in storage, although it is ready for immediate redeployment. Moreover, users can easily reconfigure it for other material handling operations such as transfer, stacking, or sorting. Consequently, it offers high flexibility for integration into diverse industrial settings.

Control System and Integration

The system includes a dedicated FANUC control cabinet, which incorporates all required safety features. Specifically, it offers emergency stops, protective barrier sensors, and remote access interfaces. In addition, the robot features 8 digital inputs and 8 digital outputs mounted on the upper arm, along with 2 integrated pneumatic lines. These components allow for quick connection of peripheral devices, including grippers and detection sensors. Therefore, integration with auxiliary systems is simple and efficient.

Power Supply and Operating Conditions

In terms of power, the Used Robot Palletizer FANUC 10800 bph operates on three-phase 380–575 V at 50/60 Hz. Its average power consumption remains low at 2.5 kW, which contributes to overall energy efficiency. Furthermore, the unit functions reliably in ambient temperatures from 0 to 45 °C, and it maintains a low acoustic noise level of 70.5 dB.

Footprint and Integration Readiness

Thanks to its compact 771 x 610 mm footprint, the system easily fits into both existing and newly designed production layouts. Additionally, it communicates with PLCs and SCADA platforms using standard industrial interfaces. As such, it enables synchronized operation with conveyors, vision systems, or labeling modules. Consequently, the robot supports full automation of end-of-line processes.

Technical Conclusion

In conclusion, the Used Robot Palletizer FANUC 10800 bph offers a robust, adaptable solution for bottling lines demanding high-speed performance and precise handling of large containers. Besides its mechanical capabilities, the system includes full technical documentation and a documented maintenance history. Therefore, end users can deploy it with confidence in both existing and future automation projects.