Description

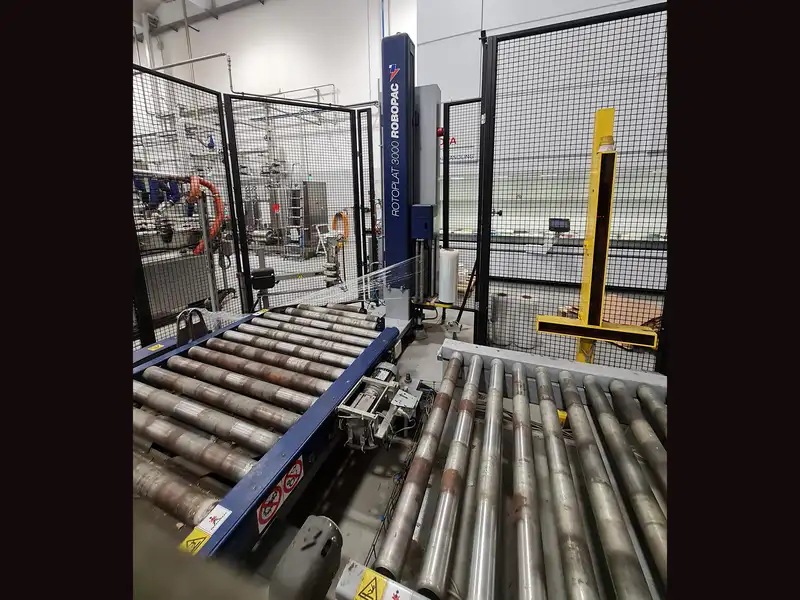

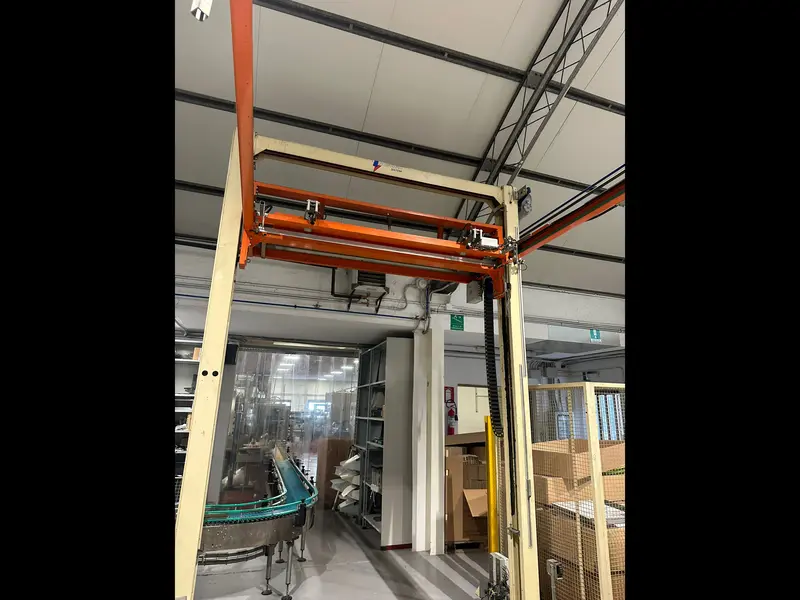

Used Palletizer and Stretch Wrapper KETTNER UM1200 14000 BPH

In excellent condition, the machines are still indoors, so it’s ready for sale immediately.

As requested by your total overhaul of the used equipment is at your disposal the work phases: so with the bottling machines washing operation used palletizer pre-assembly mechanical operation; indeed with check repair with replacement of delicate parts; such as bearings etc.

This used palletizer painting with sandblasting of interesting parts, so it is keeping the same RAL Replacement of all.

PAL Control and compliance of the complete machine-side system Electrical panel with PLC replacement; indeed, it uses SIEMENS OR SIMILAR. Control and standardization of electrical panel with verification and replacement of Demange parts. Complete system disassembly and assistance for packing and loading for transport.

Bottling machines delivered FOB Italy seaport.

How this used equipment work?

This bottling machine foresees an infeed system with a single-lane;

This already implies that the production speed is a medium-low speed due to the single inlet.

As a result, an electronic palletizer must realize all the required recipes and pallet configurations based on the bottle formats used by the buyer.

These bottling machines are very easy equipment; they will just be connected with the rest of the existing line of the buyer.

We also deliver pallet wrappers in conjunction with our palletizers; which rotate on a rotating platform, applied in rotation. Two machines used are connected in sync and are automated in compliance with the existing used bottling line.

In the case of purchase with maintenance, a functional test will be performed in our workshops before delivery.