Description

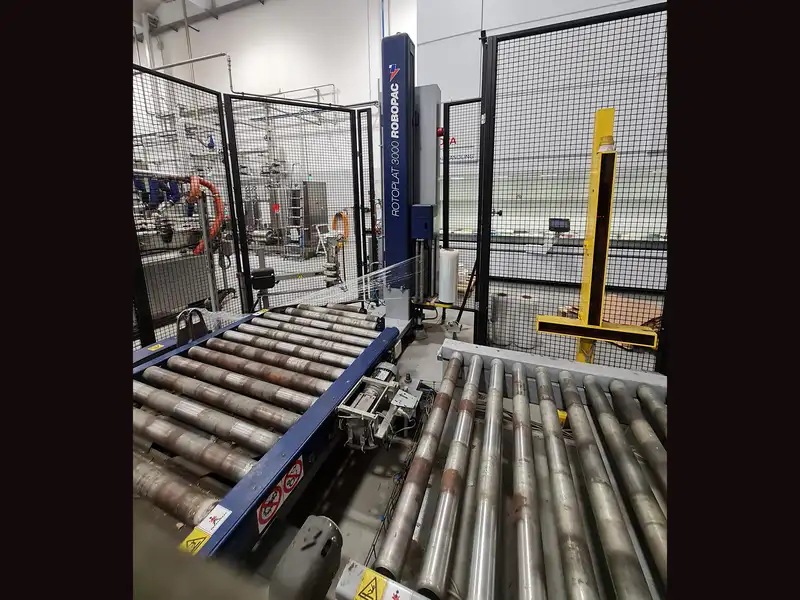

Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS 12000 bph

The Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS 12000 bph offers a professional solution for automatic pallet wrapping in high-output industrial environments. The Italian manufacturer Robopac designed and built this machine in 2014 to stabilize pallet loads using stretch film. As a result, the unit remains in ready-to-run condition and supports immediate installation and commissioning.

Operating Specifications and Mechanical Structure

This system uses a rotating table to wrap pallets while keeping them stationary. Consequently, this configuration minimizes mechanical stress on the load and enhances unit stability. The Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS delivers a nominal capacity of 12,000 bottles per hour, which makes it suitable for high-speed automated production lines.

Moreover, the machine processes standard pallet sizes, including European pallets (1200×800 mm) and American pallets (1219×1016 mm). It also handles loads up to a maximum height of 2000 mm, allowing operators to adapt the unit to multiple logistics configurations and industrial applications. In other words, it offers flexibility across various sectors.

Furthermore, the rotating-table configuration enables precise film application without compromising load stability. In addition, the rugged mechanical design ensures consistent operation over extended production cycles.

Electronic Control and Operator Interface

Robopac equipped the machine with a Siemens Simatic HMI PLC, which ensures reliable operation and straightforward integration into existing automation systems. As a result, the machine offers seamless control and quick adaptability. The control system allows operators to manage parameters, monitor wrapping cycles, and perform remote diagnostics.

Not only does the Siemens interface support custom programming, but it also enables compatibility with modern SCADA systems. Therefore, technicians can configure the Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS 12000 bph for various line requirements with minimal effort.

Additionally, the HMI interface simplifies operator training and speeds up troubleshooting. As such, the machine reduces downtime and boosts overall efficiency.

Power Consumption and Mass of the Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS

The machine runs on 400 Volts, at a frequency of 50 Hz, and draws a maximum of 4.5 kW. These electrical specifications comply with standard European industrial infrastructure. Consequently, installers can integrate the unit into existing systems without requiring electrical reconfiguration.

The unit weighs 1190 kg, and plant engineers must consider this mass during layout design, particularly for flooring and material handling systems. Above all, the weight reflects the robust build quality required for intensive use.

Safety, Documentation, and Operational Status

Robopac included all required safety systems on the machine to comply with applicable regulations. These features include emergency stops and physical guards that protect operators during operation and maintenance. Additionally, the safety systems contribute to reduced risk and regulatory compliance.

The unit comes with complete technical manuals, and Robopac can provide inspection reports upon request. Hence, maintenance teams can access full documentation for servicing and commissioning. The Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS currently operates correctly and does not require any major servicing.

The machine will be available starting from January/February 2026.

Importantly, the documented maintenance history further validates its readiness for immediate deployment.

Technical Summary of the Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS

Industrial operators who need a high-speed, heavy-duty pallet wrapping solution can rely on the Used Pallet Wrapper Robopac ROTOPLAT 3000 PGS. Thanks to its rotating table design, support for major pallet formats, and programmable Siemens control system, the machine ensures consistent performance and integration flexibility.

In conclusion, technicians can deploy this unit quickly and maintain high levels of wrapping efficiency over time. Ultimately, the machine offers a dependable and scalable solution for industrial packaging lines.