Description

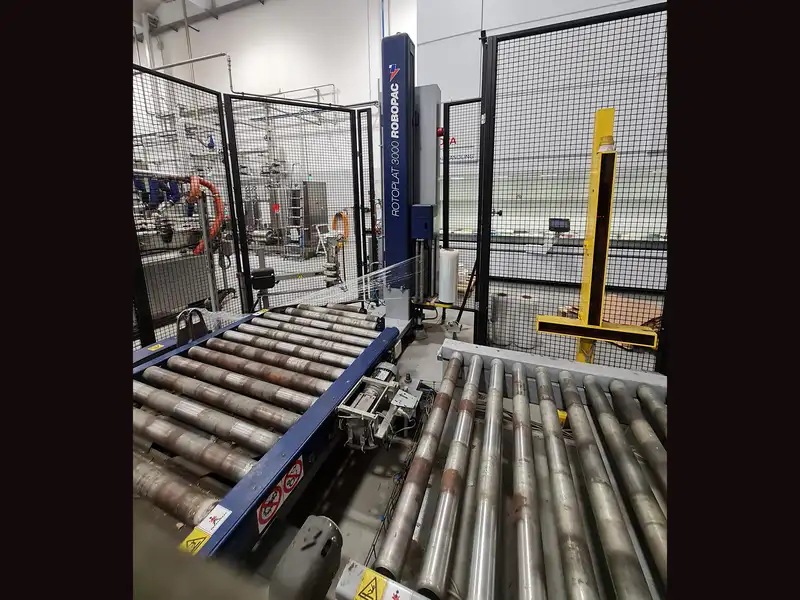

Used pallet wrapper Robopac 2008 – 40000 BPH

Construction Details and Operational Parameters

The Robopac 2008 pallet packer represents an engineering solution for industrial automation. It’s with particular attention to the handling and stabilization of palletized loads. With a rotary ring system, this unit handles winding operations at a quantifiable speed of 40,000 BPH. The machine accepts Europallet formats, integrating itself into existing processing lines and adhering to size and capacity standards. This interoperability demonstrates its adaptability within already operational logistics systems.

Security and Maintenance Protocols in the used pallet wrapper Robopac 2008 – 40000 BPH

Compliance with industrial safety directives is highlighted by the presence of accident prevention protections. This is essential to prevent accidents during the operation of the machinery. At the same time, the availability of overhauls indicates a systematic approach to maintenance, essential to mitigate operational wear and prevent functional failures. Aspects that could compromise production continuity and workplace safety.

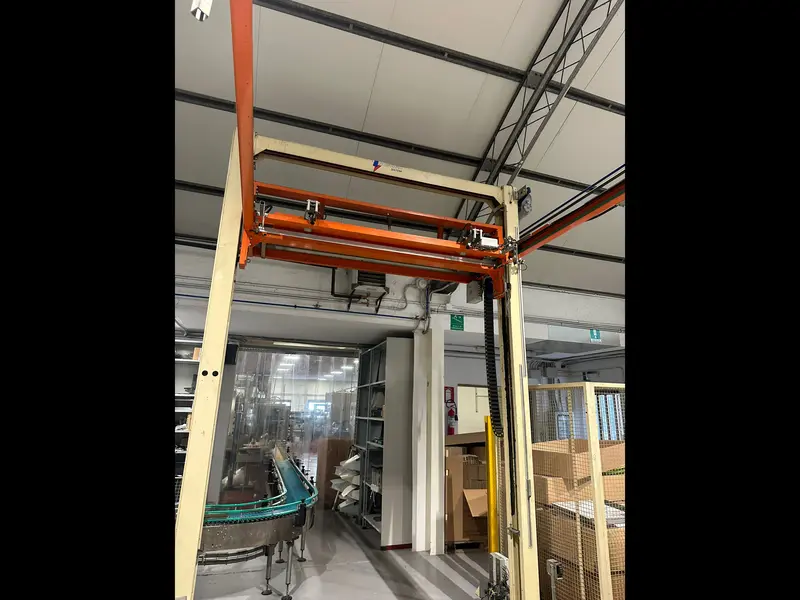

Logistics and Operational Preparation

The unit, located in Italy, is stored disassembled, and adequately packaged to prevent structural damage. A detail that attests to the methodology used to safeguard mechanical integrity during the inactivity phase. This storage practice aims to minimize any degradation due to environmental or transport variables. Ensuring efficient installation and reducing the time required for commissioning.

Movement Mechanisms and Operational Reliability

The distinctive feature of the wrapper Robopac is the rotating arm mechanism. It’s designed to maintain constant film tension and ensure uniformity of wrapping. This precision is crucial for stabilizing loads, and reducing the risk of movement or damage during transport. The performance of the Robopac system, combined with the ability to manage different loads, confirms the operational efficiency of the machinery in a dynamic industrial scenario.

Overall Technical Evaluation of the used pallet Wrapper Robopac 2008 – 40000 BPH

In summary, the 2008 Robopac pallet packer features a set of technical specifications and construction features that reflect advanced engineering in the packaging automation industry. Every component, from mechanical design to safety features, aims to optimize production and ensure operational safety. This extends the useful life of the machinery. The technical analysis highlights the importance of considering not only immediate capabilities but also long-term logistical and sustainment implications in the context of continuous industrial operations.