Description

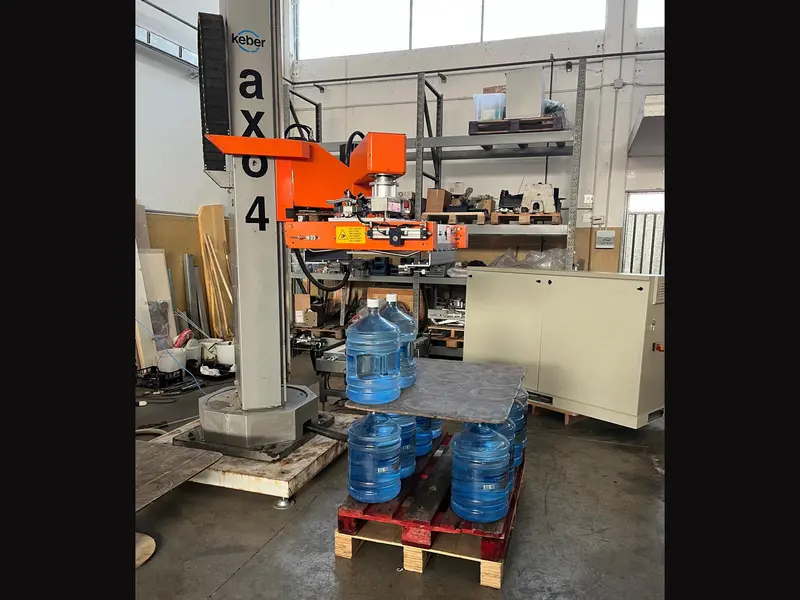

Used palettizer KEBER AXO4 700 bph

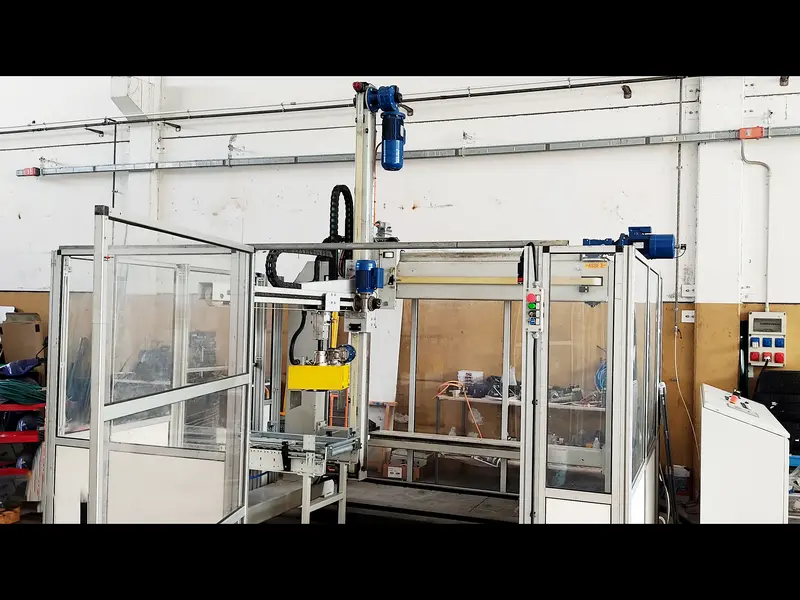

General System Description

The Used palettizer KEBER AXO4 700 bph delivers a robotic palletizing solution for high-volume operations in demanding industrial environments. KEBER built this model in 2003. The unit currently operates under stable and verifiable conditions, with 10,000 recorded hours of use confirming its reliability. Moreover, the machine has shown consistent mechanical performance, which adds value to its operational lifespan.

Production Capacity and Format Flexibility

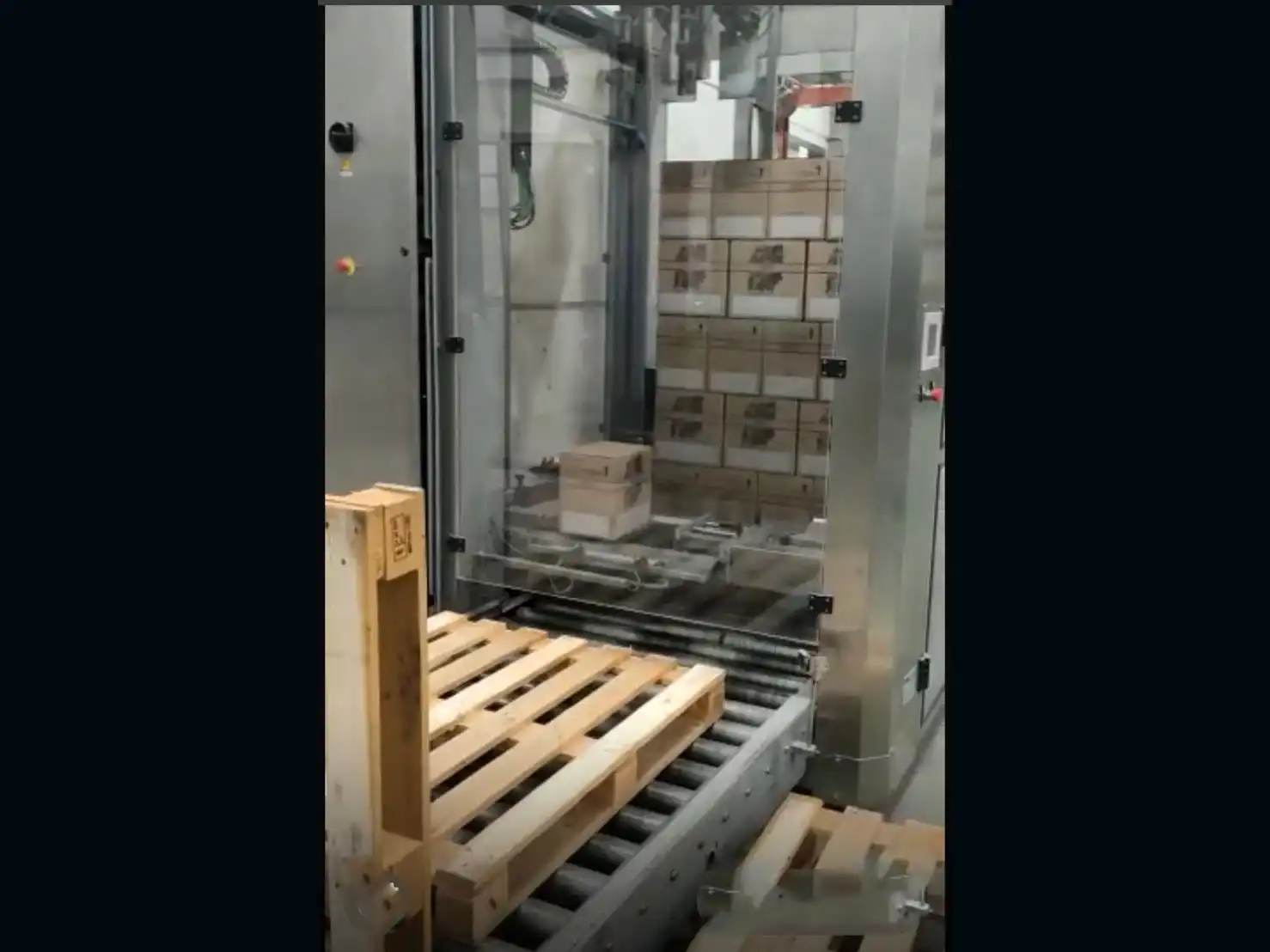

The Used palettizer KEBER AXO4 700 bph handles 4 to 6 cycles per minute, achieving an output of approximately 700 bottles per hour. As a result, it fits medium- to high-capacity bottling lines. The machine processes up to 20 container formats, allowing operators to switch between different product types with minimal reconfiguration. Consequently, production teams can meet varying packaging requirements without costly downtime.

Robotic Handling System

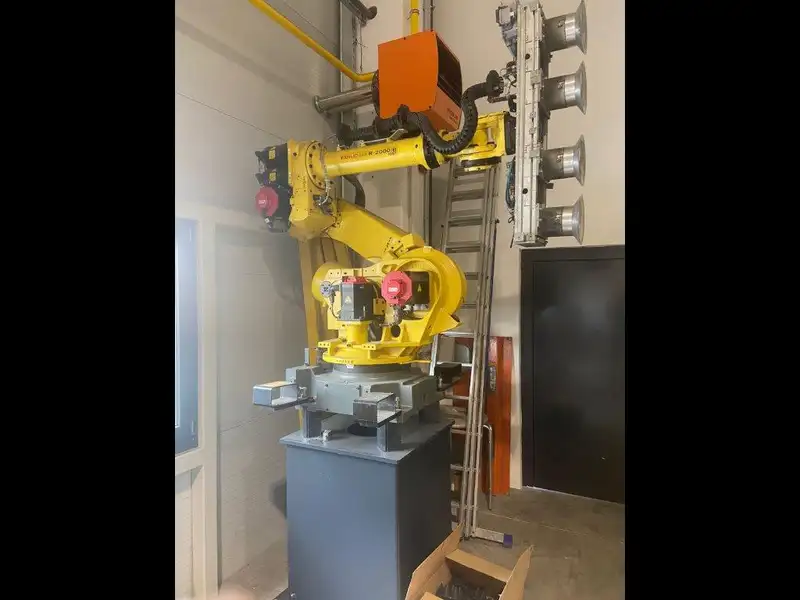

The palletizer uses a neck-gripping clamp system to transfer containers with precision and care. Unlike conventional palletizers, this robotic design eliminates mechanical limitations, improving adaptability across various layout configurations and container types. In addition, its gripping system maintains stability throughout the transfer cycle, reducing potential damage. Therefore, the unit ensures safe and accurate palletizing, even under continuous operation.

Safety Features and Technical Documentation

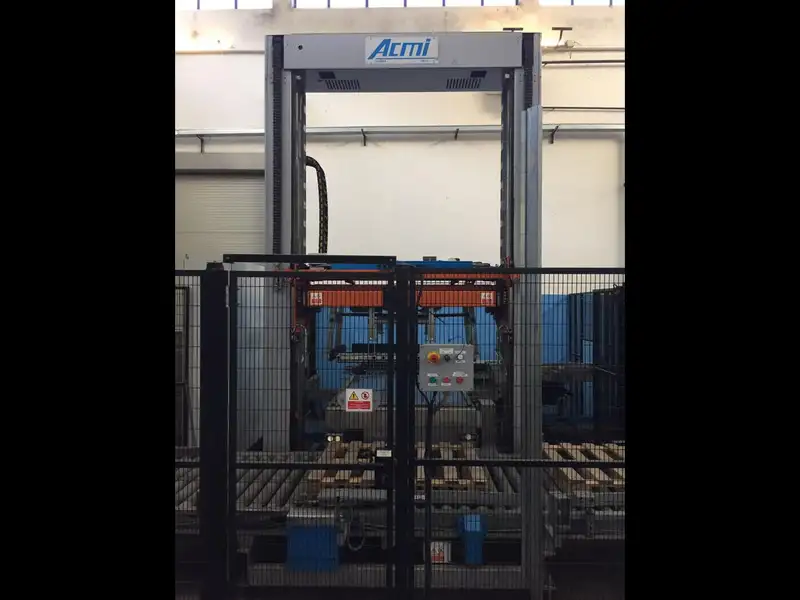

KEBER equipped the Used palettizer KEBER AXO4 700 bph with compliant safety protections, ensuring operator safety and adherence to current industrial standards. Importantly, the machine meets the safety requirements for CE-certified environments. The manufacturer also provides a complete set of technical manuals, enabling technicians to install, configure, and maintain the system effectively. Furthermore, these documents facilitate preventive maintenance scheduling and error diagnostics.

Production Line Integration

The palletizer incorporates a floor-level slip-sheet dispenser and a pallet magazine, both integrated into the frame. Thanks to this configuration, the system requires no elevated structure or platform. The unit supports 1200×800 mm and 1200×1000 mm pallet sizes, allowing users to align it with common European and international logistics platforms. As such, integration into existing layouts becomes straightforward.

Automation and Process Control

The automation system relies on a Siemens S7-300 PLC, which offers seamless integration into SCADA and HMI environments. Consequently, engineers can control, monitor, and adjust operations from central control systems. The unit operates on 400V / 50Hz and draws 15 kW of electrical power, ensuring compatibility with standard industrial infrastructures. Moreover, the power configuration supports energy-efficient operation.

Footprint and Technical Support

The Used palettizer KEBER AXO4 700 bph occupies a footprint of 6500 mm in length, 4000 mm in width, and 3200 mm in height. Before installation, technicians should verify spatial compatibility with existing plant infrastructure. The availability of spare parts enables maintenance teams to perform repairs quickly and minimize downtime. Notably, this contributes to higher uptime rates and lower maintenance costs.

Technical Conclusion

The Used palettizer KEBER AXO4 700 bph offers a high-performance robotic solution for bottling lines that require precise, reliable, and repeatable palletizing operations. Even though the unit is pre-owned, it maintains technical integrity and robust performance. Ultimately, it suits facilities that prioritize uptime, automation, and modular integration. In conclusion, the unit represents a strategic investment for production sites needing flexibility, safety, and long-term reliability.