- Home

- >

- Machines

- >

- Palletizer

Palletizer

Ref: PAL42Used Linear Robot Palletizer Langhammer LR03 720box/h

SoldDetails

kw: 7kw

hz: 50hz

Palletizer

Ref: PAL42Used Linear Robot Palletizer Langhammer LR03 720box/h

SoldRelated machines

-

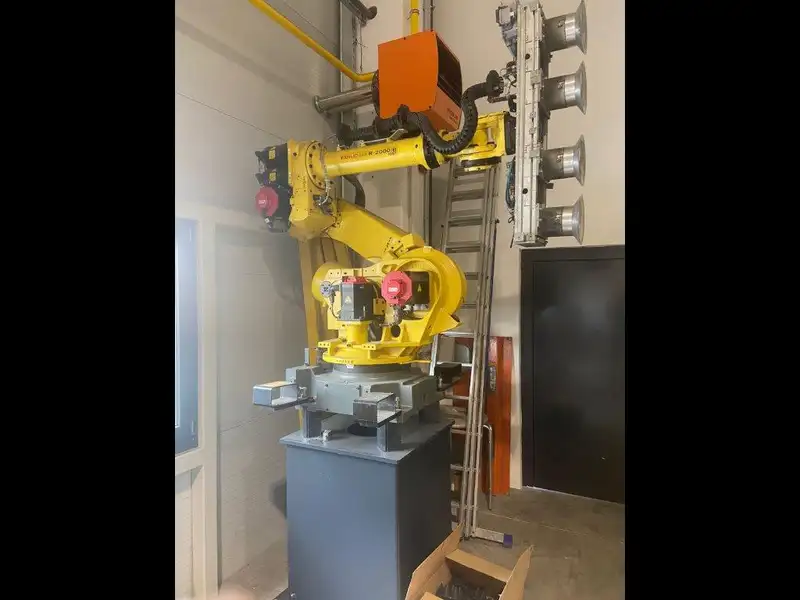

Used Robot Palletizer FANUC 10800 bph

Used Robot Palletizer FANUC 10800 bph -

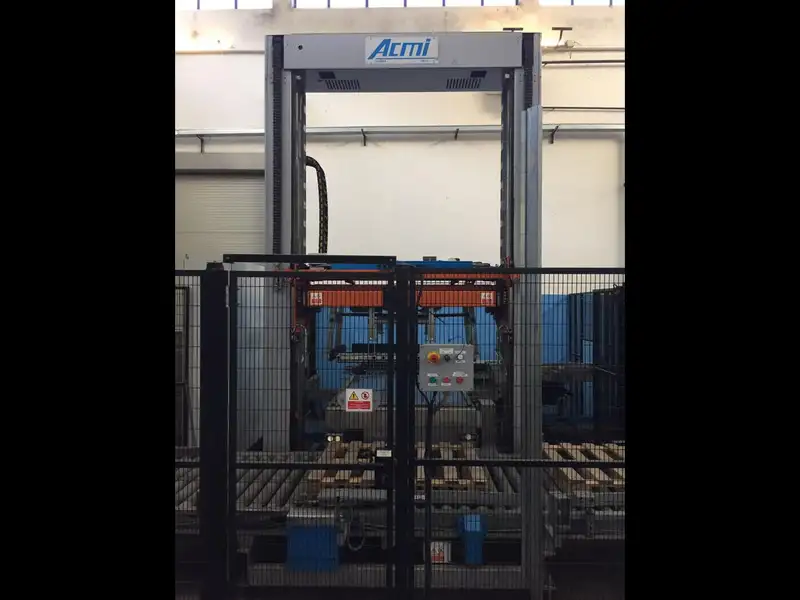

Used Palletizer ACMI RASAR P180 1600 plastic crates – hour

Used Palletizer ACMI RASAR P180 1600 plastic crates – hour -

Used Palletizer APSOL CP-G ROBOT 800 boxes/hour

Used Palletizer APSOL CP-G ROBOT 800 boxes/hour -

Used palettizer MONDO SCAGLIONE P0 up to 1000 box/hour

Used palettizer MONDO SCAGLIONE P0 up to 1000 box/hour -

Used Palletizer KETTNER Robogrip up to 2200 box/hour

Used Palletizer KETTNER Robogrip up to 2200 box/hour -

Used Palletizer TIEMME PT42 up to 3000 bph

Used Palletizer TIEMME PT42 up to 3000 bph -

Used Robot Palletizer Fanuc 2003

Used Robot Palletizer Fanuc 2003 -

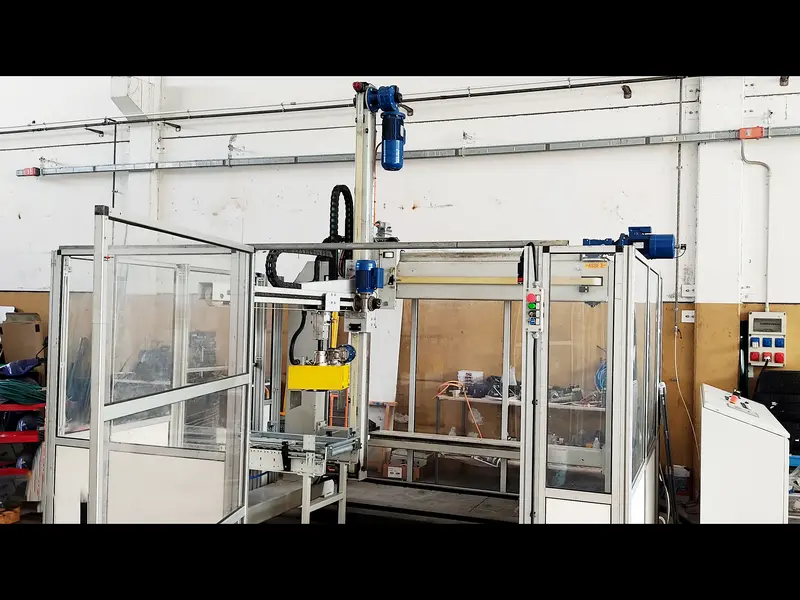

New Palletizer ROBOT-ARM PALLETIZER

New Palletizer ROBOT-ARM PALLETIZER -

Used Palletizer ABM 765BA

Used Palletizer ABM 765BA

Description

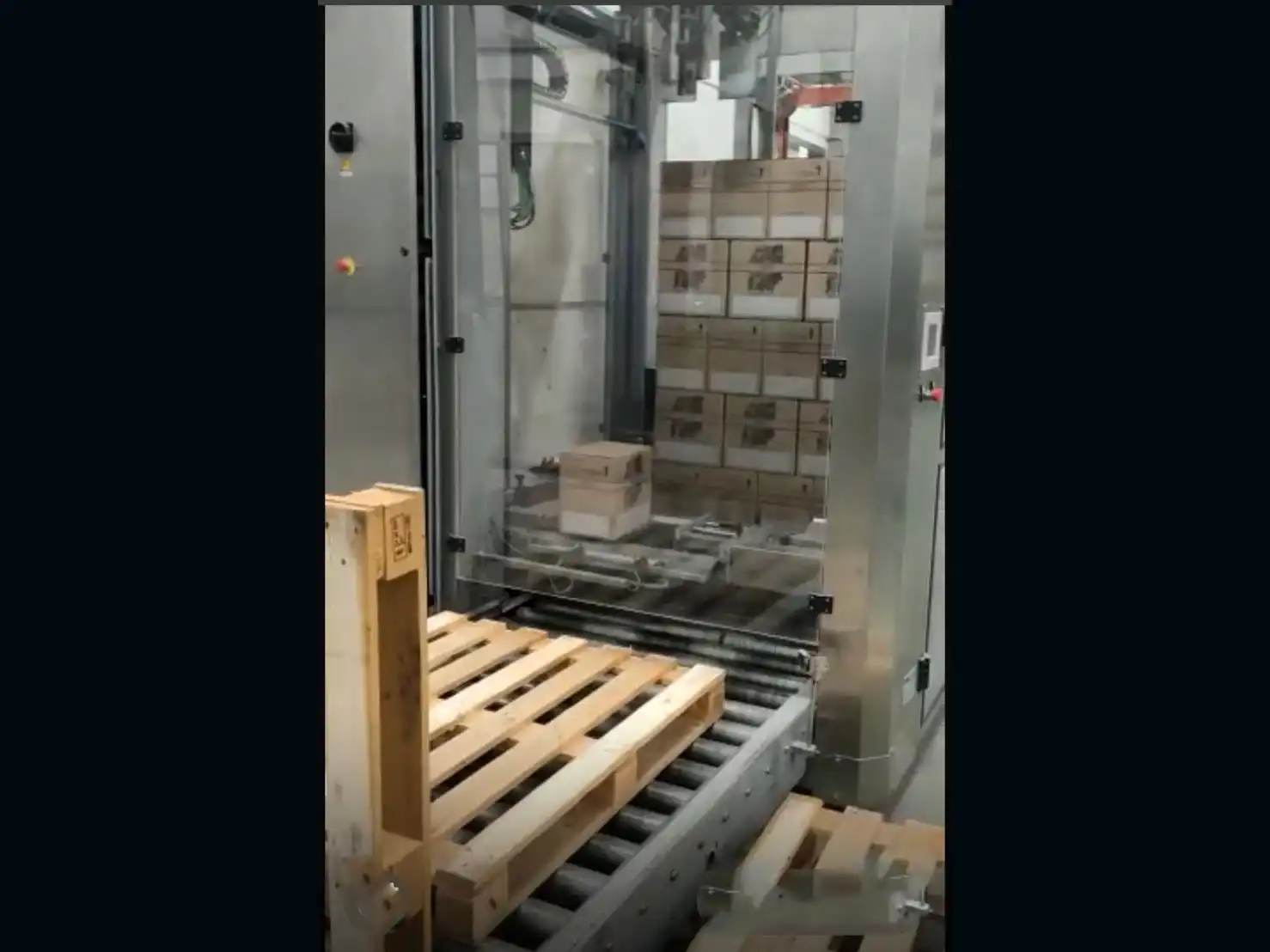

Used Linear Robot Palletizer Langhammer LR03 720box/h

Introduction to the Langhammer LR03

The Used palettizer Langhammer LR03 720box/h linear robot palettizer from 2014 offers advanced automation for palettization. Specifically, Langhammer, a reputable German brand, designed this model to enhance bottling and palettization in high-efficiency production environments.

Palletization Capacity

The Langhammer LR03 employs a robotic palettization system with a rotating arm. Consequently, it handles up to 12 boxes per minute, which equals 720 boxes per hour. Therefore, this high throughput makes it ideal for production lines with large volumes of boxes.

Box and Pallet Specifications

Moreover, the machine manages boxes weighing up to 12 kg.It also accommodates pallets with dimensions of 1200 x 800 x 2100 mm and a maximum weight of 1000 kg. These specifications, in turn, provide flexibility in handling various box and pallet sizes and weights.

Lifting Mechanism of the palletizer Langhammer

In addition, the Langhammer LR03 uses vacuum caps to lift both boxes and bundles. This lifting mechanism enhances the efficiency of the palettization process by securely gripping and moving items. Consequently, this feature ensures reliable and precise handling during operation.

Speed and Performance

The Langhammer LR03 achieves a palettization speed of 20 pallets per hour. This speed ensures smooth and continuous operation, thus optimizing production times. Furthermore, the design maintains high performance during extended operations.

Control and Power Supply

To control the machine, a Siemens PLC is used, known for its reliability and precision. The machine, therefore, operates at 3*400V with a power consumption of 7 kW. Consequently, these specifications support efficient and sustainable operation for the Langhammer LR03.

Integration and Adaptability

Furthermore, the Used Linear Robot Palettizer Langhammer LR03 720box/h integrates seamlessly with existing production systems. Its robust structure, along with its technical specifications, thus suits palettization processes that demand high speed and precision.

Conclusion of the Palletizer Langhammer

In summary, the Langhammer LR03 delivers an advanced solution for bottling and palettization. It processes up to 720 boxes per hour and handles pallets up to 1000 kg. Therefore, with its efficient vacuum cap lifting mechanism and overall performance, it supports high-intensity production environments effectively.