Description

Used Linear Magnetic Flowmeter Filler – Overview

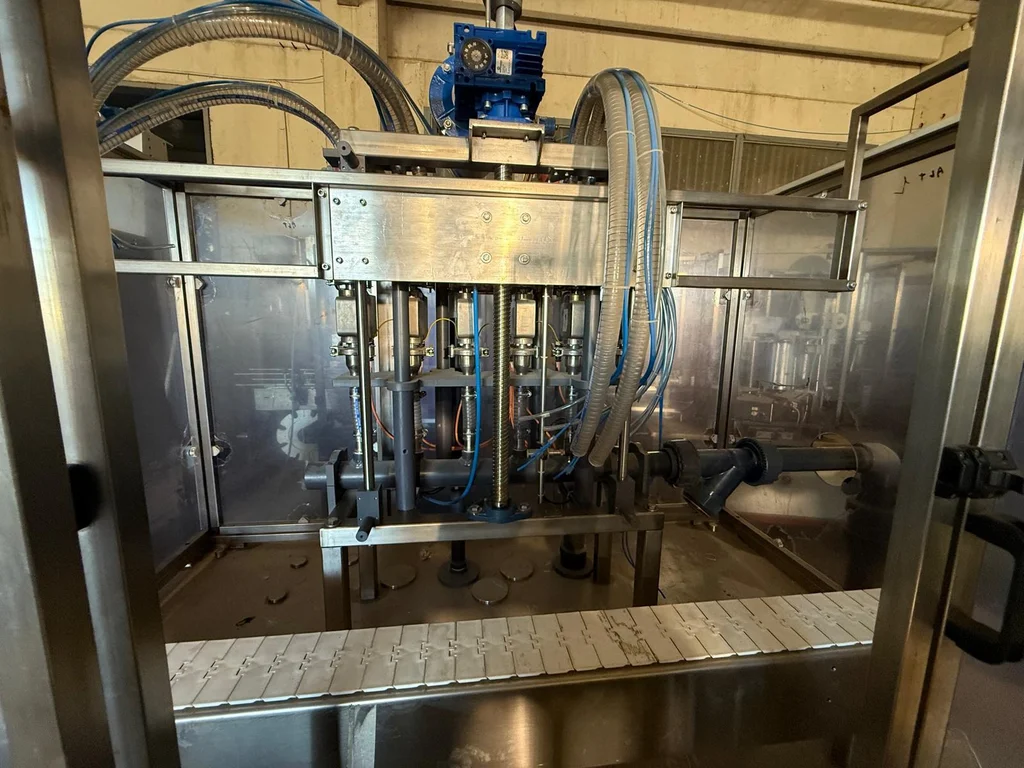

This second hand linear volumetric filling machine is engineered for PET and HDPE containers up to 5 L, ideal for used bottling line upgrades in beverage production and industrial packaging. Equipped with 6 magnetic flowmeter dosing nozzles in 316 stainless steel, a CE-compliant HMI/PLC platform, and a hygienic stainless-steel build, it delivers accurate, repeatable fills for still water, detergents and liquid soap.

Technical Specifications & Performance Data

Core configuration

- Model: Linear 6-nozzle magnetic flowmeter filler up to 5 L

- Filling principle: Volumetric dosing via magnetic flowmeters (non-isobaric)

- Nozzles: 6 x 316 stainless-steel filling nozzles with individual magnetic flowmeters

- Container materials: PET and HDPE

- Container size range: up to 5 liters

- Applications: still water, detergents, liquid soap and similar non-carbonated liquids

Mechanical design

- Electro-welded stainless-steel tubular frame with stainless-steel panels

- Integrated containment tank

- Transparent PVC safety hood with safety locks

- 3000 mm stainless-steel inlet conveyor with adjustable guides and acid-proof roller shutters

- Trolley-mounted feed pump with inverter for PLC-controlled speed variation

Performance

- High-accuracy volumetric dosing with magnetic flowmeters for consistent fill volumes

- Throughput: application-dependent (product viscosity, bottle format, and target volume). Nominal rates available on request.

Advanced Automation & Control Systems

- CE-compliant touch-screen HMI for operation, alarms, and diagnostics

- Industrial PLC for recipe management, synchronized conveyor control and dosing logic

- PLC-controlled lift for precise nozzle/bottle elevation during filling

- Inverter-driven feed pump for stable product supply and flow control

- Remote assistance capability for commissioning and troubleshooting

Production Line Integration Capabilities

Designed to integrate seamlessly within a used bottling line or mixed-brand packaging environment:

- Standard I/O for start/stop, emergency circuits and interlocks with upstream bottle handling and downstream capper/labeller

- 3000 mm stainless infeed conveyor with adjustable guides supports quick changeovers

- Suitable for integration with conveyors, cappers, labellers and end-of-line equipment in beverage production and home-care industrial packaging

Machine Condition & Maintenance History

- Condition: In storage, ready for inspection

- Documentation included: use and maintenance manual (Italian), wiring diagram

- CE marking supplied

- Remote assistance available to support start-up and training

Operational Performance & Versatility

- Accurate volumetric filling for a wide range of low-to-medium viscosity liquids

- Supplied with 1 bottle format and 1 cap format

- Quick format changeovers via adjustable guides and PLC recipes

- Hygienic stainless-steel product path for cleanability and durability

- Not isobaric: optimized for non-carbonated products

Installation Requirements & Site Preparation

- Electrical: CE-compliant electrical cabinet; industrial three-phase supply (specifications as per wiring diagram)

- Utilities: compressed air and product feed required (exact values per manual)

- Layout: filler footprint plus 3000 mm infeed conveyor; provide clearances for operation and maintenance

- Commissioning: remote assistance available; on-site integration with existing used bottling line controls recommended

Safety Standards & Compliance Certification

- CE-compliant machine with documented safety circuits

- Transparent PVC safety hood with safety interlocks for guarded access

- E-stop pushbuttons and safety locks integrated with PLC logic

- Components and electrical panel compliant with CE standards