Description

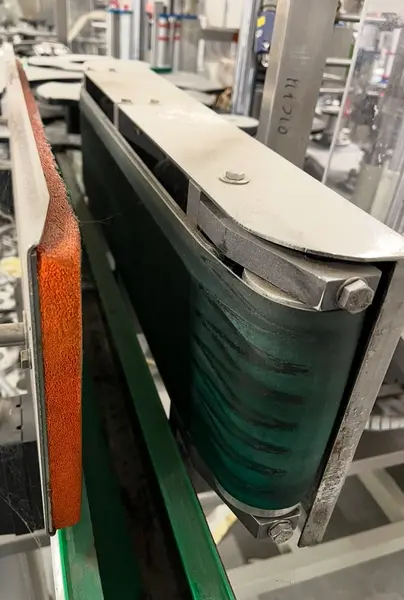

Used Labeling Machine PE LABELERS Universal Master up to 7500 bph

The Machine delivers advanced technology for labeling glass bottles, meeting production demands of up to 7500 bottles per hour. Furthermore, P.E. Labellers manufactured this machine in 2007, ensuring precise operations with its robust design and integrated features.

Technical specifications and performance of the Used PE Labellers Labeling Machine

The labeller includes eight rotating plates and five labeling stations. Specifically, three stations apply adhesive labels, while two use cold glue. The machine rotates clockwise, which streamlines bottle flow management. Additionally, its manual adjustment system for both the head and labels enables quick adaptations to different formats, thereby enhancing flexibility.

Production capacity and configuration

The labeller handles glass bottles with a maximum diameter of 120 cm and a standard 0.75-liter format. Consequently, it operates at a top speed of 7500 bottles per hour, making it ideal for medium-scale production lines. Moreover, the system applies labels to the front, back, and neck of each bottle, ensuring a high-quality, professional finish.

Labeling method and management in the Used PE Labellers Labeling Machine

This machine applies labels using adhesive and cold glue methods. Therefore, this dual approach ensures compatibility with a wide range of label designs and materials. Meanwhile, operators manually adjust the system to maintain precise control during each production batch.

Current state and operational specifications

The machine remains in storage; however, it is ready for immediate deployment. It has recorded 10,000 working hours, yet it still offers substantial operational capacity. Furthermore, its robust build, weighing 2250 kg, ensures stability and durability even under high-speed conditions.

Electrical data and power requirements

The labeller PE LABELERS Universal Master up to 7500 bph runs on 400 V, with an installed power of 5 kW and a frequency of 50 Hz. As a result, its electrical configuration meets industrial standards, ensuring efficient energy usage for extended operations. Additionally, its energy efficiency supports long-term cost savings.

Applications and technical advantages

The Used Labeling Machine PE LABELERS Universal Master up to 7500 bph ensures efficient and accurate label placement. Similarly, its versatile labeling stations handle bottles of various shapes and sizes without compromising output quality. Consequently, this versatility makes it a reliable option for many bottling operations.

Technicians and industry experts rely on this machine for its performance and customizable configurations. Above all, it represents an excellent choice for demanding bottling applications.