Description

Machine Overview

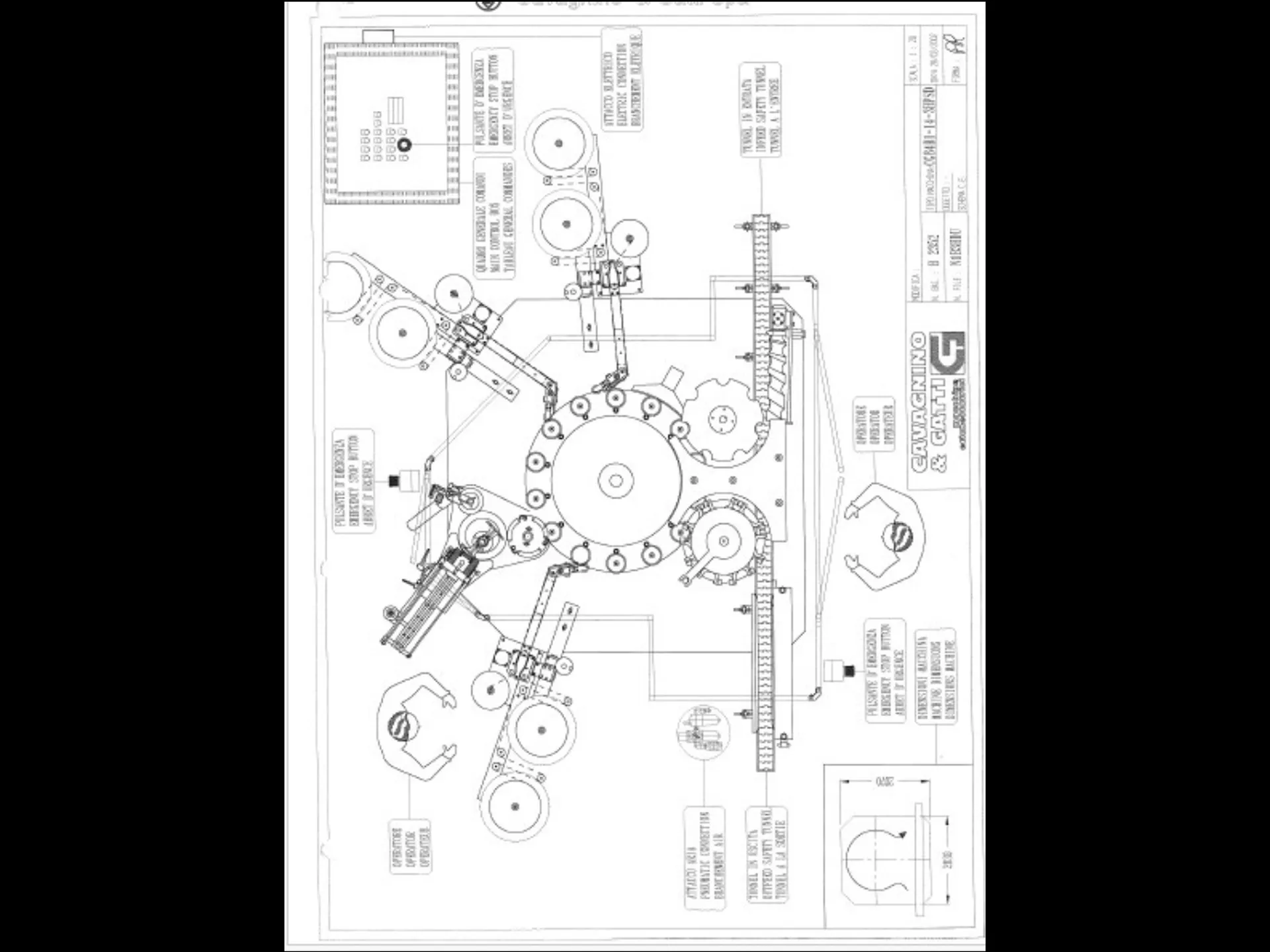

The labeling machine Cavagnino&Gatti is a rotary labelling machine manufactured by CAVAGNINO & GATTI in 2002. It features a 14-plate carousel with counterclockwise rotation and is equipped with a mixed technology configuration: three pressure-sensitive (self-adhesive) labelling stations and one cold-glue station. The machine is designed to apply front and back body labels in a single pass, with an additional station dedicated to a bottom label approximately 2 × 6 cm. This architecture enables flexible set-ups, from adhesive-only operation to hybrid cycles where a cold-glue label (e.g., tax strip or wrap component) is combined with pressure-sensitive labels.

The 14 rotating bottle plates provide stable container handling for consistent label placement. Typical applications include glass or PET containers across beverages and specialty foods, as permitted by the installed change parts. The machine’s robust stainless-steel construction and IP54-rated electrical system suit industrial bottling environments.

Key Technical Data

- Manufacturer / Model: CAVAGNINO & GATTI – Rotary Labeller

- Reference: ET225

- Year of manufacture: 2002

- Carousel: 14 plates, counterclockwise rotation

- Labelling technology: 3 × pressure-sensitive (self-adhesive) stations + 1 × cold-glue station

- Label positions: Front and back body labels; additional bottom label (~2 × 6 cm)

Automation & Control

- Rotary motion with variable speed control for synchronized infeed, carousel and outfeed.

- 24 VDC control circuits with instrumentation at 24 VAC/230 VAC per design data.

- Sensors for container presence and label detection typical of pressure-sensitive and cold-glue processes.

- Operator controls for station enable/disable, speed adjustment and format selection (change parts required per format).

Line Integration

- Designed for inline operation with upstream filler/capper and downstream inspection/packaging equipment.

- Standard 24 VDC I/O handshaking signals can be used for start/stop, fault and safety interlocks.

- Mechanical interfaces for infeed and outfeed conveyors and starwheels; alignment and timing performed on the rotary carousel.

- Provision to run pressure-sensitive stations independently or in combination with the cold-glue station, enabling multiple labelling scenarios in a single pass.

Condition & Maintenance

- Pre-owned unit (year 2002). Actual condition and scope of supply to be verified at inspection.

- Recommended preventive service on wear items: label peeler edges, pressure rollers, belts, bearings, cold-glue rollers/pots and scraper elements.

- Cold-glue circuits should be inspected for build-up; adhesive stations should be calibrated for web tension and label positioning.

- Routine checks: sensor alignment and sensitivity, bottle plate leveling, station registration, guarding and safety interlocks.

Performance & Versatility

- Capable of front/back labelling with an additional bottom label in one pass, leveraging mixed adhesive technologies.

- Suitable for paper or film labels (pressure-sensitive) and paper labels (cold glue), subject to material compatibility and station configuration.

- 14-plate carousel supports medium-speed operations; actual output depends on container geometry, label dimensions, adhesives and process settings.

- Format flexibility achievable with appropriate change parts for containers and labels.

Site Requirements

- Electrical supply: 400 V ±5%, 50 Hz, 3P + N + PE (separate neutral and protective earth).

- Control voltages: 24 VDC auxiliaries; 24 VAC / 230 VAC instrumentation circuits.

- Environmental conditions (design data):

- Ambient temperature: 5 °C to 40 °C

- Relative humidity: 30%–80% (non-condensing)

- Maximum altitude: 1000 m a.s.l.

- Hazardous/explosive atmospheres: not permitted

- Flooring: level, load-bearing industrial surface with clearance for guarding and service access.

- Ancillaries: dry compressed air and extraction may be required by auxiliary devices depending on the final configuration (to be verified during line audit).

Safety & Compliance

- IP54 protection on electrical system and motors for industrial environments with routine wash-down (non-high-pressure) and dust exposure.

- Fixed and interlocked guards with emergency stop circuits typical of rotary labellers; safety performance to be confirmed at commissioning.

- Installation, risk assessment and validation must be carried out according to applicable machinery and electrical standards and the end user’s safety procedures.