Description

Used Labeling Machine BRB GLOBUS 2800 bph

The Used Labeling Machine BRB GLOBUS 2800 bph, model MEGA ADE 411 CW, reliably applies self-adhesive labels to glass and PET bottles. BRB GLOBUS manufactured this machine in 2016, ensuring it remains fully operational. Moreover, it operates with a clockwise rotation system, achieving a production capacity of 2800 bph.

Structural and Functional Features of the Used Labeling Machine BRB GLOBUS

The Used Labeling Machine BRB GLOBUS 2800 bph measures 2500 x 1400 x 2050 mm and weighs 1500 kg, making it compact and stable for seamless integration into existing bottling lines. Furthermore, its mechanical structure maximizes operational efficiency and includes a self-adhesive full wrap-around labeling station, which fully covers each container.

Additionally, the machine’s movement system relies on mechanical cams, which precisely position containers on the rotating plates. By eliminating electronic motorization for plate movement, the design minimizes maintenance requirements and ensures long-term reliable operation. Consequently, this system enhances durability and efficiency.

Supported Bottle Types and Formats

The BRB GLOBUS 2800 bph labeling machine handles glass and PET bottles, including those subjected to empty bottle pressurization for PET and cans. Due to its adaptability, this versatility allows it to process various bottle formats efficiently. Supported formats include:

- Glass bottles: 200ml, 250ml, 330ml, 500ml, 750ml

- PET bottles: 500ml

According to the technical manual, detailed formats include:

- Transparent PET: Diameter 64 mm, height 214 mm, capacity 0.5 L

- Transparent glass:

- Diameter 61 mm, height 213.5 mm, capacity 0.33 L

- Diameter 78.5 mm, height 286 mm, capacity 0.75 L

Given these specifications, the machine supports a wide range of applications, ensuring compatibility with various production requirements. In addition, it enhances operational flexibility, making it ideal for manufacturers with multiple bottle formats.

Labeling System

The Used Labeling Machine BRB GLOBUS 2800 bph utilizes a self-adhesive labeling method and applies full wrap-around labels to containers. Thus, this system ensures consistent and high-quality labeling results.

Operators manually adjust both the labeling system and the head position, allowing flexibility for different container sizes. At the end of the labeling process, an additional label smoothing system guarantees perfect adhesion, preventing wrinkles or imperfections that could impact the final product’s appearance. Furthermore, this smoothing mechanism enhances the visual appeal and durability of the labels.

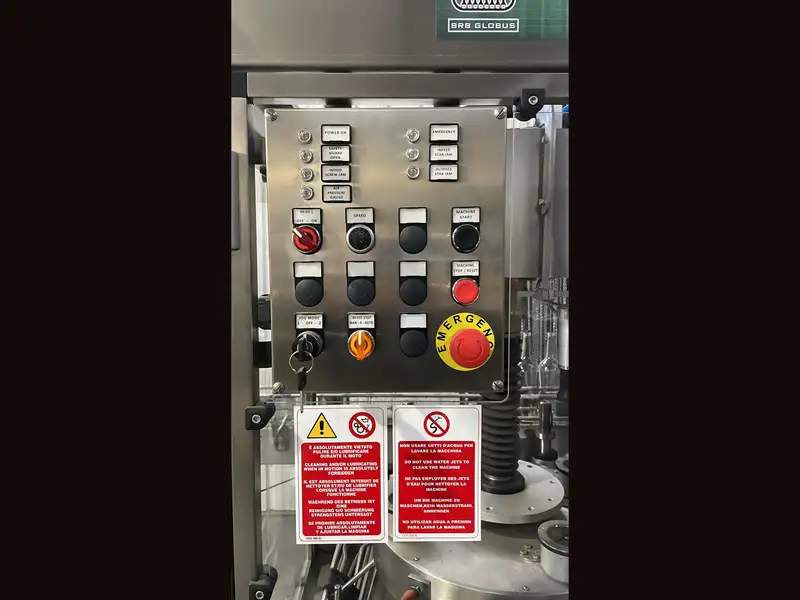

Safety and Technical Documentation

The machine includes safety devices that comply with current regulations. Additionally, it comes with technical manuals and maintenance documentation, equipping operators with all necessary information for installation, operation, and routine servicing. As a result, users can operate the machine with confidence, knowing they have access to comprehensive support materials.

Technical Specifications

- Number of stations: 1 (self-adhesive full wrap around)

- Plate movement: Mechanical cams

- Label adjustment: Manual

- Head adjustment: Manual

- Availability of spare parts: Yes

Conclusion of the Used Labeling Machine BRB GLOBUS

This used labeling machine efficiently labels glass and PET bottles. Its self-adhesive labeling station and mechanical cam movement system deliver precision and long-term reliability. In addition, this machine optimizes production processes by minimizing downtime and maintenance needs. Designed for medium-scale production, it ensures ease of use and seamless integration into existing bottling lines. Consequently, manufacturers can achieve consistent, high-quality labeling with minimal effort..