Description

Used KHS Innofill Canning Line up to 24000 cph

The Used KHS Innofill canning line 24000 cph represents an advanced solution for bottling, operating at a speed of 24,000 cans per hour (BPH). This line is specifically designed for standard 0,33L, 0,44 L and 0,33L Sleek, making it ideal for products like beer and soft drinks. Furthermore, it integrates various high-quality components to ensure seamless operations.

Machinery Description

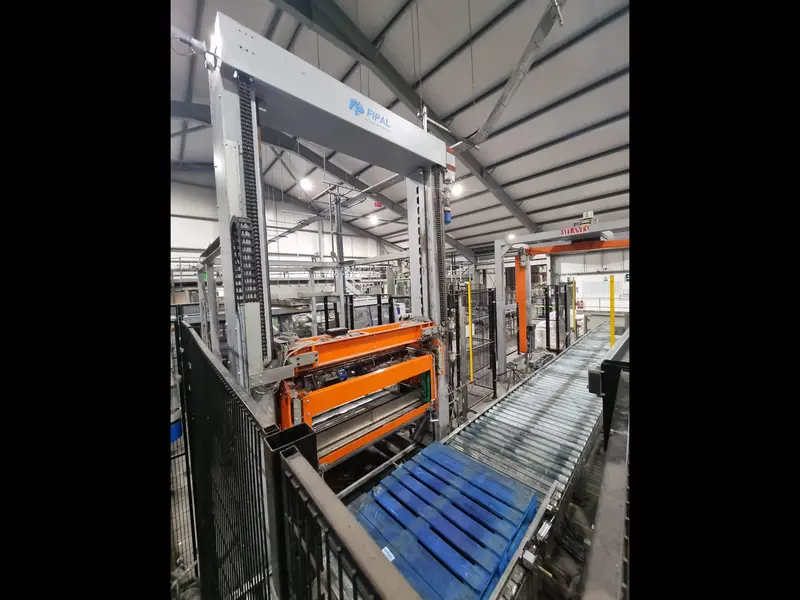

The bottling line includes a wide range of high-quality machinery. First of all, the depalletizer FIPAL MINIDEPAL 20 LA from 2015 ensures a continuous and automated supply of cans. Moreover, the heart of the line is the filling machine KHS Innofill Can DVD 40 from 2015, renowned for its precision and reliability in filling. Additionally, this machine contributes significantly to the overall efficiency of the line.

Sealing and Feeding Systems

The seamer FERRUM F6 from 2014 ensures a hermetic seal of the cans, maintaining product quality. Moreover, the lid feeding system CSW Mini-Multifeeder / 54-MMF0191 from 2015 integrates the sealing process with a continuous flow of lids. Consequently, this integration enhances the overall efficiency and reliability of the bottling line.

Transport and Connection in the KHS Innofill canning line

The Eurosistemi conveyors connect all the components of the line, ensuring a continuous flow of cans through the various stages of the bottling process. In addition, the Eurosistemi can drying unit TF1/TF2, with its two configurations (single and double), prepares the cans for inspection and labeling. Therefore, this preparation step maintains high-quality standards.

Quality Control and Inspection

The Heuft Spectrum TX lid checker with rejection system ensures that only perfect cans move to the next stage. Furthermore, the Teledyne Taptone PROS-136FS inspector adds an additional layer of quality control. Additionally, the FT System inspector from 2017 serves as a checkweigher with a rejection station, ensuring that each can meets weight standards. As a result, these quality control measures significantly reduce the risk of defects.

Labeling and Packaging

The Premier Labeller P250 labeling machine applies precise and uniform labels to each can. For packaging, the line features two wrapping systems: the Robopac Prasmatic TC400 compact wrap around packer from 2022 and the GPI Graphic Packaging International Quikflex 300 wrap around packer from 2018. These systems ensure secure and compact packaging of the cans. The wrap arounds run 24 X 0,33 L at the speed of 34,000 cph. Moreover, these systems work in tandem to streamline the packaging process.

Palletizing and Final Packaging

The FIPAL Pal 80 F palletizer and the Atlanta Revolution LS pallet wrapper from 2015 complete the process, ensuring that packaged cans are ready for shipping. Additionally, the Revolution LS lane dividers and combiners correctly position cans for the palletizer. Consequently, this ensures that the final stages of packaging are both efficient and reliable.

Efficiency and Integration

The Used KHS Innofill canning line 24000 cph offers maximum efficiency and integration among the various components. Each piece of machinery ensures smooth operation and consistent quality of the final product. Furthermore, the Hitachi UX printer provides the ability to print directly on the cans, adding further flexibility to the line. As a result, the overall process becomes more streamlined and adaptable to various production needs.

Conclusion of the KHS Innofill canning line

In conclusion, the Used KHS Innofill canning line up to 24000 cph , thanks to its advanced configuration and high-quality machinery, represents a complete solution for the bottling needs of beer and soft drinks. The speed of 24,000 cans per hour and the reliability of the components guarantee efficient and high-quality production. Therefore, the Used KHS Innofill canning line 24,000 cph is an ideal choice for modern bottling plants, ensuring both performance and reliability.