Machine type

Manufacturer

Model

Year

Notes

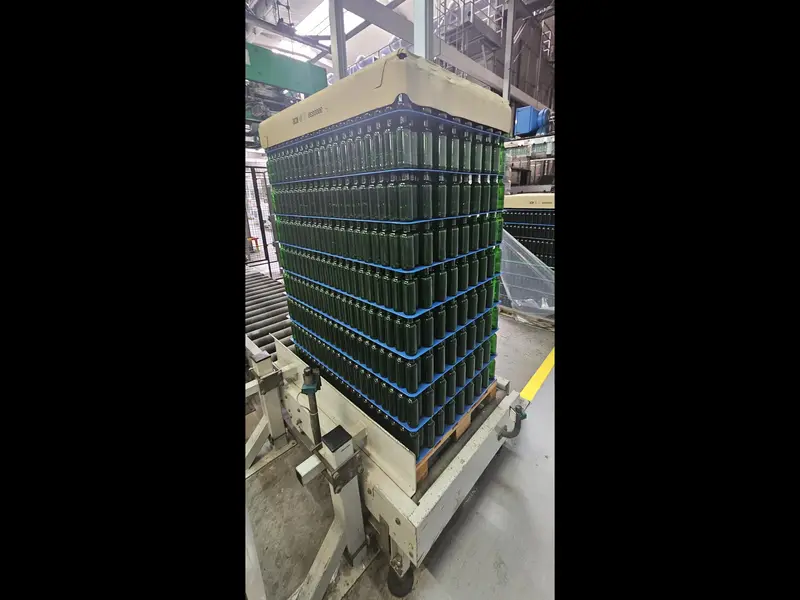

Machine type

Depalletizer

Manufacturer

Transpak

Model

Royal

Year

2001

Machine type

Premix

Manufacturer

Procomac

Model

Starmix-e

Year

2000

Machine type

Rinsing Machine

Manufacturer

Procomac

Model

Gripstar

Year

2001

Machine type

Filling Monoblock

Manufacturer

Procomac

Model

Ecofill

Year

1998

Machine type

Conveyors

Manufacturer

Procomac

Year

1998

Machine type

Labeling Machine

Manufacturer

Krones

Model

Contiroll 600-10

Year

2003

Machine type

Shrink Wrapper

Manufacturer

Dimac

Model

Star P30

Year

2005

Machine type

Wrap Around Packer

Manufacturer

Sotemapack

Year

1993

Machine type

Palletizer

Manufacturer

Transpak

Model

Mag-p

Year

1993

Notes

Overhauled in 2001