Description

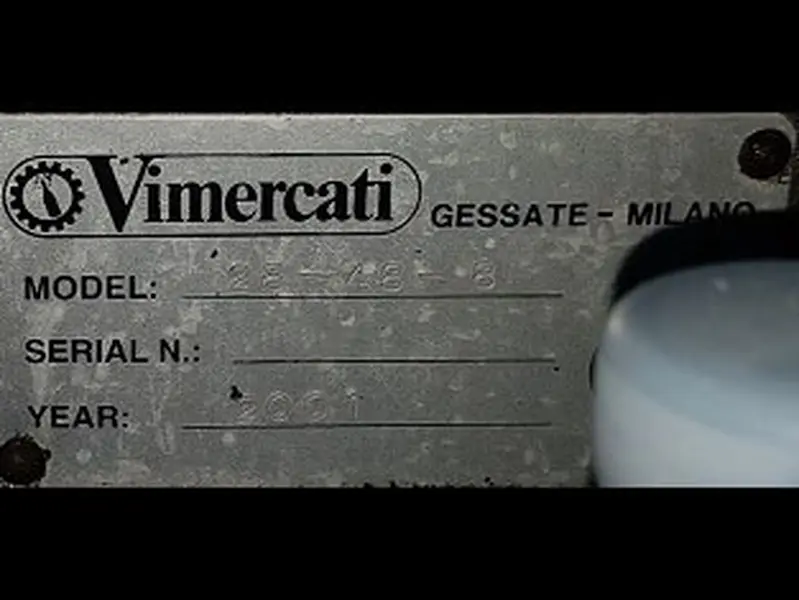

Used Isobaric Filling Triblock VIMERCATI 28-48-8 Year 2001

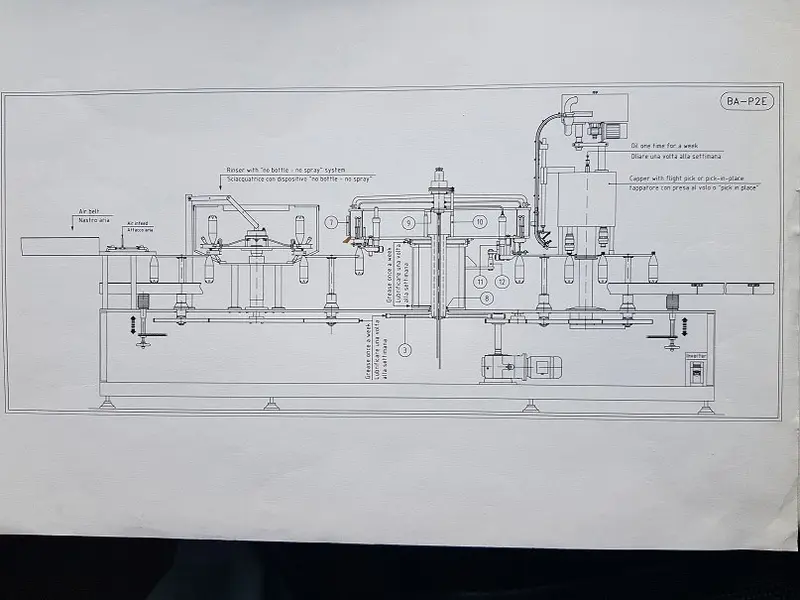

Firstly, the VIMERCATI 28-48-8 bottling system, created in 2001, is notably advanced for the bottling industry, especially for isobaric filling. This document meticulously offers a comprehensive analysis, focusing on its detailed specifications and also covering its application in beverage filling.

Production Capacity and Versatility

Moreover, the triblock boasts a capability of processing 8000 bottles per hour (BPH). It’s exceptionally efficient for a variety of PET container formats: 0.50 L, 1.0 L, 1.5 L, and 2 L. Such unparalleled flexibility meets diverse production needs and adapts to changing market demands seamlessly. The filling monoblock has the following speed for each formats:

- 1,5 L – 7500 bph (If filling sparkling water)

- 1,5L – 6500 bph (if filling CSD)

- 0,5 L – 8000 bph

Rinsing Component of the Filling Triblock Vimercati 28 – 48 – 8

Additionally, it features 28 grippers for thorough container treatment. This essential stage ensures containers are impeccably clean before the filling process. It adeptly removes any residues and contaminants, ensuring the utmost hygiene.

Isobaric Filling

Furthermore, forty-eight valves are meticulously equipped for the filling process, employing the isobaric method. This innovative technique maintains a constant internal pressure, which is critical for preserving quality in carbonated beverages such as sodas and sparkling water. Fixed-type nozzles ensure precise and uniform liquid distribution, significantly minimizing the risk of oxidation and CO2 loss.

Capping of the Filling Triblock Vimercati 28 – 48 – 8

Similarly, eight heads are utilized to apply plastic screw caps, specifically the type 1881. This step guarantees that containers are sealed airtight, thereby preserving the integrity of the product efficiently.

Current Conditions and Logistics

Currently, in storage, the triblock measures 3250 mm by 3500 mm by 2900 mm and weighs 6000 kg. Its clockwise rotation facilitates effortless integration into existing production lines, which promotes significant workflow optimization.

In conclusion, the used isobaric filling triblock VIMERCATI 28-48-8 from 2001 combines efficiency, versatility, and technical precision in a remarkable manner. It is suitable for various container formats and incorporates advanced isobaric filling technology, making it a valuable asset for bottling companies striving for the highest quality and hygiene standards. This thorough analysis underscores the critical role of such machinery in enhancing beverage production processes effectively.