Filling Monoblock

Ref: M173

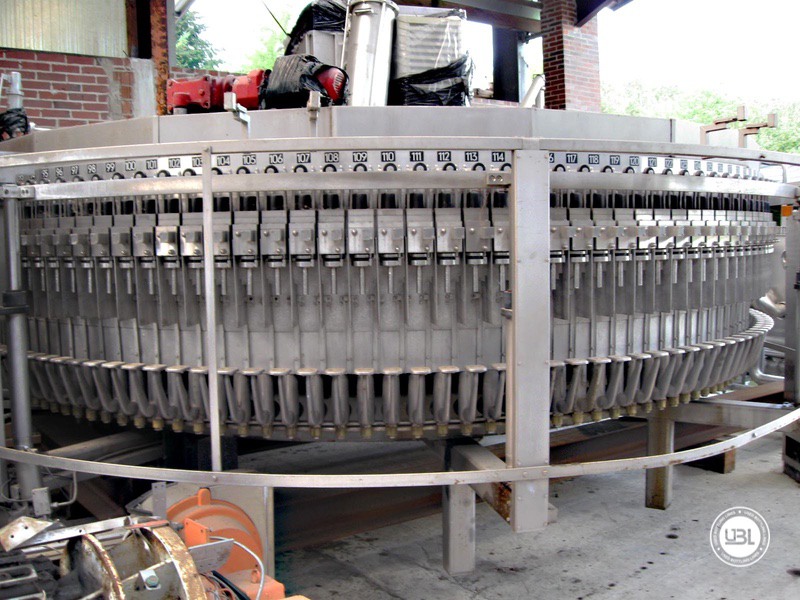

Used Isobaric Filling Monoblock KHS Glass Bottles 45.000 bph

In storage

Manufacturer:

KHS

Model:

Innofill-ER VF 143/20

Year:

1994

Speed:

45000 BPH

Products:

Soft Drinks, Water (Sparkling), Water (Still)

Containers:

Glass

Formats:

0.70 L, 0.75 L

Details

Electrical data:

hz: 50hz

Safety features:

Yes

Manuals:

Yes

Rotation:

Counterclockwise

Filler:

No. of valves: 143

Fill type: Isobaric

Type of nozzle: Fixed

Isobaric valve: Traditional

Capper:

Cap type: Aluminum screw

No. of heads: 20

Cap size: 20 Alcoa

Isobaric:

Yes

Filling Monoblock

Ref: M173

Used Isobaric Filling Monoblock KHS Glass Bottles 45.000 bph

In storage

Manufacturer:

KHS

Model:

Innofill-ER VF 143/20

Year:

1994

Speed:

45000 BPH

Products:

Soft Drinks, Water (Sparkling), Water (Still)

Containers:

Glass

Formats:

0.70 L, 0.75 L

Request information

Further information, photos and layouts are available for each machine. Click on Request information in case you need more data.

DISCLAIMER: The operational status of each machine is monitored on a monthly basis. Therefore we will promptly update the current status of the machine only at the time of your request.

Description

Used Isobaric Filling Monoblock

In as is condition, without guaranty.

For filling of soft drinks into glass bottles.

System: KHS Innofill-ER VF 143/20.

Number of filling valves: 143.

Number of screw capping heads: 20 (Alcoa) for aluminum screw caps.

Capacity: 40.000 bph a 0,7l (lemon, cola)

45.000 bph a 0,7l (mineral water, lemonade)

45.000 bph a 0,75l (mineral spring water)

(These beverage were produced by the former machine owner!)

Built: 1994.

Working direction: left-right.

Pitch of filling valves: 105 mm.

With switch cabinet, PLC Siemens S5/115U.

Electrical connection: 230/400 V, 50 Hz.

Control voltage: 24 V, DC.

Incl. documentation and all available auxiliauries