Description

Used Injection Molding Machine AOKI year 2014

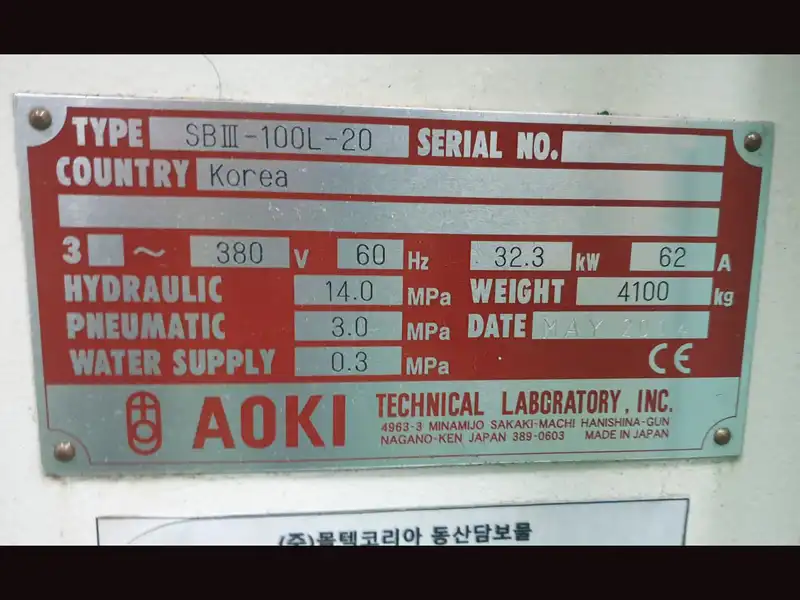

The Used Injection Molding Machine AOKI year 2014 represents a highly efficient and precise solution in the field of packaging, specifically designed for the production of preforms for plastic bottles through the injection and molding process. Manufactured by Aoki Technical Laboratory, Inc., a recognized leader in molding technology for packaging, this machine offers reliable performance with a proven track record. The model SBIII-100L-20, produced in May 2014, is a used machine in excellent condition, providing exceptional value to companies looking to integrate it into their existing production lines. Moreover, the machine’s advanced features and high output make it suitable for large-scale production environments.

Injection and Molding Technology

The Used Injection Molding Machine AOKI year 2014 utilizes the highly advanced injection process, which is ideal for producing high-quality containers. These containers include preforms for beverages, detergents, and cosmetics, all requiring specific standards for shape, weight, and strength. The injection system ensures that the plastic is injected into the mold with precision, creating a uniform preform that can then be expanded using the molding process. This process enables manufacturers to produce high-quality, consistent bottles with minimal defects.

This combination of features makes the machine highly effective for industries where high volumes of bottles are required, such as beverage production and packaging. Furthermore, the SBIII-100L-20 model can produce preforms with a capacity of about 2500 CC per cycle, making it capable of handling both small and large bottle sizes. The machine is equipped with features that allow it to work efficiently with various bottle dimensions, such as 80 mm for the mouth diameter, 105 mm for the body diameter, and a height of 335 mm.

Electrical and Hydraulic Specifications of this Used Injection Molding Machine AOKI

One of the key advantages of the Used Injection Molding Machine AOKI year 2014 is its robust electrical and hydraulic design. The machine operates at 380V voltage and a frequency of 60Hz, providing the necessary power for consistent and reliable performance. It consumes a total power of 32.3 kW and requires a current of 62A, making it energy-efficient for its high output. The hydraulic system works at a pressure of 14.0 MPa, which ensures optimal performance when injecting and shaping the preforms. The pneumatic system operates at 3.0 MPa, providing additional support for the molding process. Additionally, the machine needs a water supply pressure of 0.3 MPa, allowing it to run smoothly in various industrial setups.

This high level of specification makes the machine adaptable to a wide range of production requirements and ensures that it can handle various materials and production rates effectively. The inclusion of both hydraulic and pneumatic systems provides precision in every cycle, while the robust electrical components contribute to energy efficiency and reduced operational costs.

Machine Dimensions and Production Capacity

In terms of physical dimensions, the Used Injection Molding Machine AOKI year 2014 is designed to fit in standard industrial spaces while still offering a high production output. The machine measures 3.51 m in length, 1.27 m in width, and 3.15 m in height, with a total weight of 4100 kg. These dimensions allow it to fit in most production facilities without taking up excessive space, making it ideal for both small and large-scale operations. Furthermore, the relatively compact design does not compromise its capacity or efficiency, making it a great option for companies looking to optimize their existing production lines.

Production and Preform Capacity

The machine is specifically designed to produce preforms with an 80 mm mouth diameter, 105 mm body diameter, and 335 mm height. This makes the Used Injection Molding Machine AOKI year 2014 highly versatile, capable of producing a wide range of containers. These features allow manufacturers to customize the machine for specific production needs, adjusting the parameters as required for different types of products. Additionally, the 2500 CC per cycle capacity ensures that high volumes of preforms can be produced in a relatively short time, allowing businesses to meet the demands of large-scale production runs.

Energy Efficiency and Durability

The machine is built with energy efficiency in mind, incorporating advanced hydraulic and electrical components that minimize energy consumption while maintaining high output levels. The hydraulic system, in particular, is designed for high-speed operations, ensuring that production cycles are fast and efficient. The machine also features durable components, including a sturdy frame and long-lasting parts that help reduce maintenance costs and extend the machine’s operational life. This makes the Used Injection Molding Machine AOKI year 2014 a reliable investment for businesses seeking consistent, long-term performance.

Conclusion of this Used Injection Molding Machine AOKI

In conclusion, the Used Injection Molding Machine AOKI year 2014 provides a technical and advanced solution for the production of preforms. It is particularly suitable for businesses looking to integrate a high-quality used machine with high production capacity into their existing manufacturing processes. The machine’s robust design, advanced features, and efficient technology ensure that it meets the demands of modern production lines, making it an ideal choice for optimizing plastic container production. With its impressive specifications, high energy efficiency, and long-term reliability, this machine offers an excellent balance of cost-effectiveness and performance.