Description

Please note that this single machine are not sold individually but are part of this bottling line: CLICK HERE

Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph Year 2014

General Technical Description

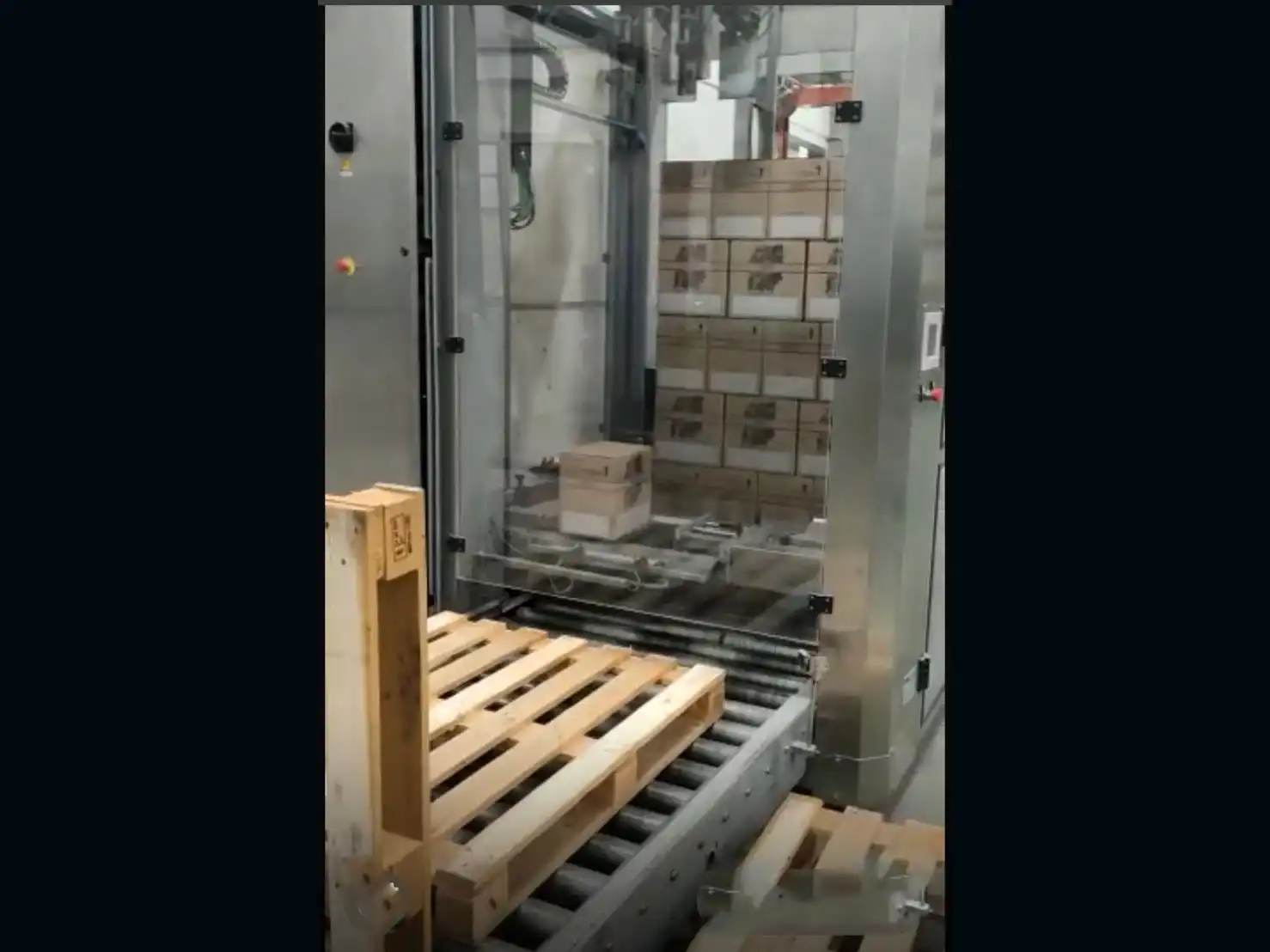

The Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 is an industrial machine designed for high-speed palletizing of bottles. With a capacity of up to 16,000 bottles per hour, it efficiently handles large-scale production demands. The machine is engineered to accommodate various bottle types and sizes, offering versatility across different industrial applications.

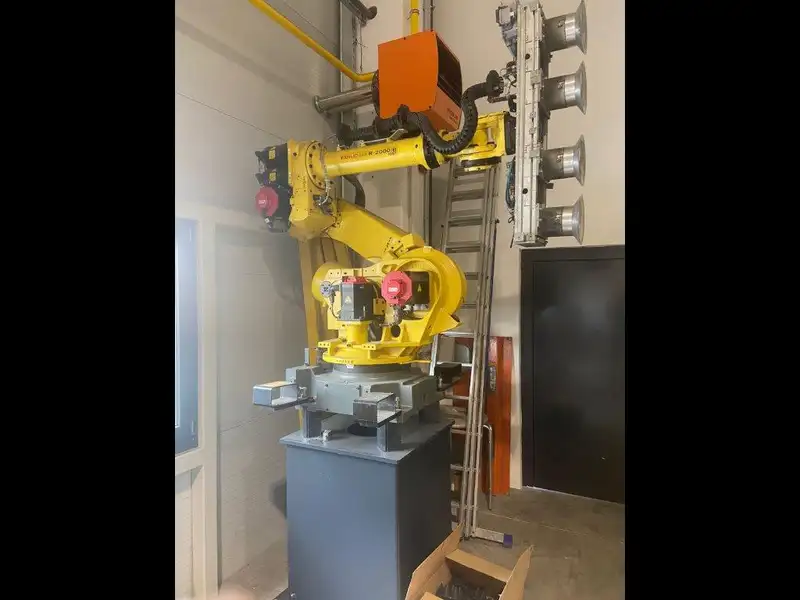

Mechanical and Structural Features

Constructed with a robust stainless steel frame, the palletizer ensures durability and long-term operational reliability. It utilizes advanced mechanical components for precise positioning and stacking of bottles onto pallets. The system incorporates servo-controlled axes that provide smooth and accurate movements, reducing mechanical stress and wear.

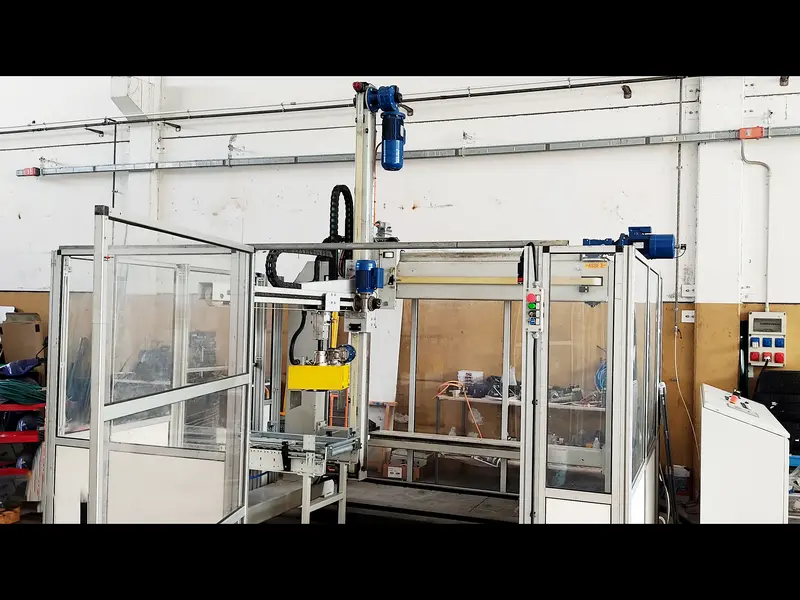

Automation and Control System

Equipped with a state-of-the-art PLC control system, the palletizer allows for precise management of the palletizing process. The touch-screen HMI interface offers operators real-time monitoring and easy adjustment of operational parameters. The Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 supports programmable palletizing patterns, enhancing operational flexibility.

Bottle Handling and Compatibility

The machine is capable of handling a wide range of bottle shapes and materials, including glass and plastic. Its gripping mechanisms are designed to securely hold bottles without causing damage. Adjustments can be made to accommodate different bottle sizes and pallet dimensions, making it adaptable to various production requirements.

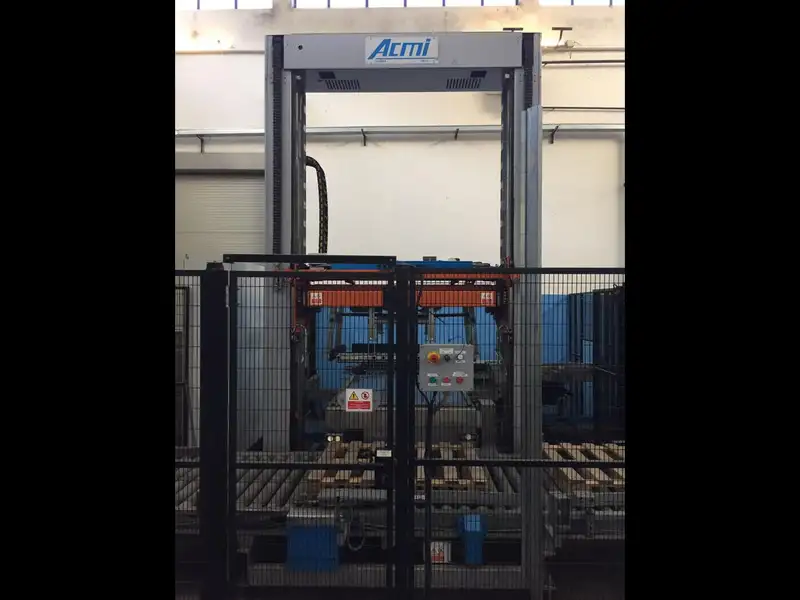

Safety and Compliance

Safety features are integrated throughout the machine, including protective guards and strategically placed emergency stop buttons. The palletizer complies with international safety standards, ensuring a secure working environment for operators. Sensors and interlocks prevent operation if safety conditions are not met, safeguarding both personnel and equipment.

Integration and Communication

The palletizer can be seamlessly integrated into existing production lines. It supports standard communication protocols, allowing synchronization with upstream and downstream equipment. This facilitates coordinated operations and optimizes overall line efficiency. The Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 enhances productivity through smooth integration.

Maintenance and Reliability

Designed for ease of maintenance, the machine features accessible components for quick servicing. High-quality parts and materials contribute to its longevity and reliable performance. Predictive maintenance features may be included, alerting operators to potential issues before they lead to downtime. This ensures the palletizer remains operational with minimal interruptions.

Energy Efficiency

The palletizer employs energy-efficient motors and control systems to minimize power consumption. Variable frequency drives adjust motor speeds based on load requirements, reducing energy usage. This not only lowers operational costs but also reduces environmental impact. The Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 represents a sustainable choice for modern production facilities.

Applications in Industry

Ideal for the beverage, food, and pharmaceutical industries, the palletizer handles high-volume packaging needs. It automates the palletizing process, reducing manual labor and minimizing the risk of product damage. Companies looking to improve operational efficiency will find the Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 to be a valuable asset.

Technical Conclusion

In summary, the Used Full Automatic Bottle Palletizer Bortolin Kemo 16000 bph year 2014 offers a robust and efficient solution for high-speed palletizing operations. Its advanced automation, flexibility, and reliability make it an excellent addition to modern production lines. Integrating this machine can lead to higher throughput and consistent product handling quality.