- Home

- >

- Machines

- >

- Depalletizer

Depalletizer

Ref: DEPAL34Used Full Automatic Bottle Depalletizer Bortolin Kemo 16000 bph year 2014

SoldDetails

Depalletizer

Ref: DEPAL34Used Full Automatic Bottle Depalletizer Bortolin Kemo 16000 bph year 2014

SoldRelated machines

Description

Please note that these single machine are not sold individually but are part of this bottling line: CLICK HERE

Technical General Description

The used full automatic bottle depalletizer Bortolin Kemo from 2014 is a machine designed for high-speed depalletization. With a production capacity of 16,000 bottles per hour, it efficiently handles large volumes in demanding industrial environments. The machine is optimized for bottles of various formats, making it versatile for different applications.

Mechanical and Structural Features

The structure is made of AISI 304 stainless steel, ensuring corrosion resistance and operational longevity. The system uses a full-layer manipulator with a gripping head equipped with suction cups or mechanical clamps, depending on the type of bottle. Pallet movement is managed via motorized roller conveyors synchronized with the operational cycle.

Automation and Control System

Equipped with a Siemens S7 PLC, the depalletizer offers precise control over operational sequences. The human-machine interface (HMI) touch screen allows operators to monitor and adjust parameters in real-time. Brushless servomotors ensure smooth and precise movements, enhancing efficiency and reducing cycle times.

Consumable Material Management

The system provides automatic removal of dividers and interlayer protections, with dedicated stations for accumulating waste materials. This minimizes manual intervention and optimizes production flow. Optical sensors detect the presence and correct positioning of materials, ensuring seamless operation.

Safety and Regulatory Compliance

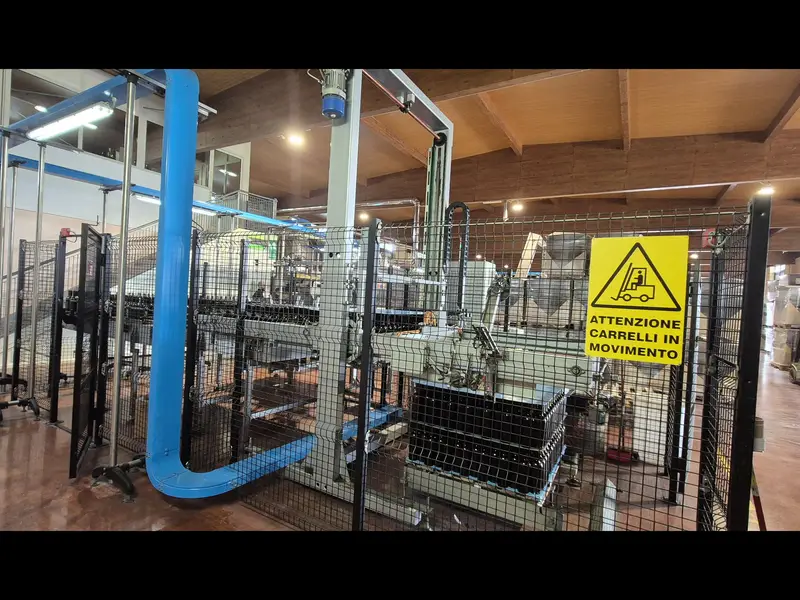

The machine complies with CE regulations regarding industrial safety. Physical protection devices like barriers and guards prevent access to hazardous areas during operation. Easily accessible emergency systems allow immediate shutdown in case of anomalies or risk situations.

Integration and Industrial Communication

The depalletizer can be integrated into existing production lines thanks to standard communication protocols such as Profibus or Profinet. This facilitates data exchange with other machines and SCADA systems, allowing centralized management and monitoring of the entire production line.

Maintenance and Operational Reliability

Its modular design simplifies preventive and corrective maintenance operations. Strategic access points enable quick interventions on critical components. The machine is equipped with self-diagnosis systems that notify any malfunctions, reducing downtime and increasing operational reliability.

Energy Efficiency and Environmental Impact

The use of high-efficiency motors and optimization of operational cycles contribute to reduced energy consumption. Additionally, the machine is designed to minimize noise and vibrations, improving the working environment and complying with regulations on acoustic emissions.

Specific Industrial Applications

The used full automatic bottle depalletizer Bortolin Kemo 16000 bph year 2014 is ideal for industries in the beverage, food, and pharmaceutical sectors. Its ability to handle different types of containers makes it suitable for bottling lines of water, wine, beer, and liquid products in general.

Technical Conclusions

This depalletizer represents an advanced technical solution for optimizing depalletization processes in high-productivity industrial environments. The combination of robust mechanical technologies and advanced control systems ensures high performance and long-term reliability.