Description

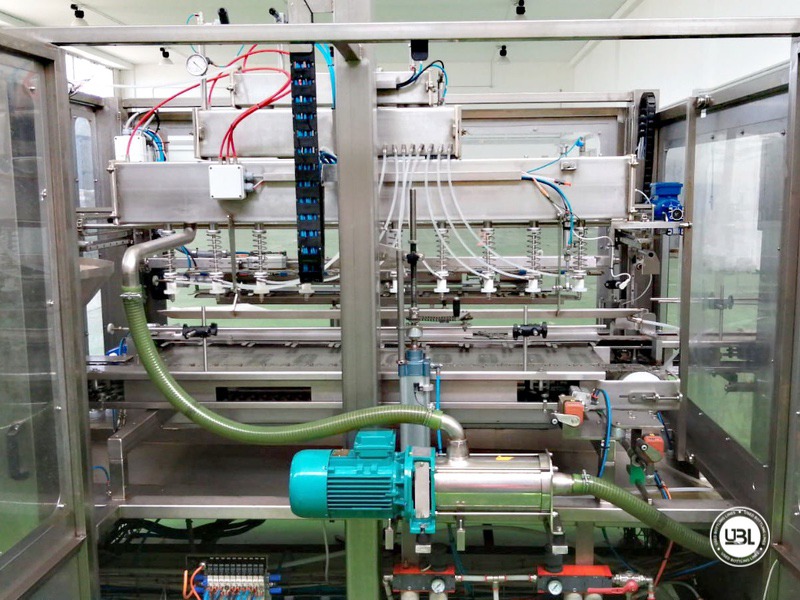

Used filling monoblock for Oil and spirits – Polaris model B6 – speed max 1500 BPH

WHY CHOOSE A POLARIS LINE mod B6 for OIL and spirits;

We summarize the main characteristics of our used filling monoblock; and which make them UNIQUE on the market:

• Elasticity of work that allows you to switch from one bottle format to another. Acting with simple operations and without replacing parts of the machine; this flexibility is also particularly suitable for those who carry out the third party.

• Speed of the format change that can be carried out from 10 to 30 minutes at the most. Given the reduced times, the line can be easily used even for small production batches.

• Use of any bottle format; cylindrical, square, triangular, amphorae, flasks, etc. from 0.100 to 2lt in glass and PET.

• We designed our labeling system, in such a way as to guarantee the maximum laying precision, on each type of bottle.

Lines B6 Can Be Composed By The Following Machine Parts:

- 10 place rinsing machines uses water from the aqueduct or recyclable liquid. (In this case you can add a recycling unit consisting of a pump)

- 5 micron filters and liquid storage tank.

- 10 place blow molding machines, as an alternative to the rinsing machine, if the bottle cannot be wet before filling. The blowing machine allows you to blow prepared air or nitrogen inside the bottle.

- 10 nozzle fillers. Depending on the type of product.

Different types of filling can be used and specifically:

- Vacuum in the bottle; (for oils, syrups, spirits or when you want a quick filling).

- By gravity, with initial slight depression (for wine or foamy liquids).

- Pressure (for PET bottles or for particular liquids).

Automatic washing system inside the filler – Used filling monoblock POLARIS

Leveler: which allows obtaining the legal content, It is possible to change the bottle format without changing the nozzle thickness.

Capper that can apply various types of caps: screw, pressure, mushroom and Guala etc. To change the type of cap, it is necessary to change a capper accessory.

Heat shrink or foil capsule dispenser.

For the restriction of the retractable capsules, a restriction stove equip the line for the closure of the foil capsules, and mount rolling heads.

Labeling machines for the application of self-adhesive labels on the front, back on the neck or other parts of the bottle.

Operational heads for the application of fiscal seals both with paper and glue and self-adhesive L to U, side.

Thermal transfer stamp for printing dates of reads and lot numbers on the back label or an ink jet marker, laser, can be applied.

Accident prevention protections according to CE standards with doors or electronic barriers.

All materials in contact with the product are for food use as per CE regulations.

In addition, you can add other equipment to carry out further operations, such as:

- Equipment for other types of caps.

- Nitrogen inject.

- Orientation for bottles with a notch on the bottom, on the side or with the handle.

- Dispensers for liquid and solid essences.

- Capper for the application of ecological cork / plastic satin stoppers.

- Recycling group for rinsing liquid.

- Caps elevator for automatic loading.

- Multistory capsule magazine. Adjusting the labeller is quick and easy to perform.

About Polaris – Used filling monoblock POLARIS

Polaris pre-owned liquid filling machine creates bottling lines created to meet the specific needs of those who want to automatically pack the most varied bottle shapes.

Starting from the most common ones such as cylindrical and square bottles; the Polaris used filling monoblock can work without any difficult with also truncated cone bottles; rectangular amphorae with or without handles, flasks, bottles with friezes engraved in the glass, etc.

The Polaris used filling monoblock is indeed oriented towards maximum flexibility of bottle formats; it has technical characteristics that differ substantially from other machines on the market.

On the Polaris lines and used filling monoblock, a chain transport the bottles which; with simple and quick adjustments, adapts to the shape and size of the bottle itself; without replacing any part of the machine.

In conclusion, they do not use stars, dispensers, augers or other accessories specific to the shape and capacity of the bottle; which must be replaced every time when the format change; entailing additional costs for their purchase, and long and laborious format changes.

Used filling monoblock B6 line size change:

On this used filling monoblock, the format change takes place mainly with manual adjustments and with the help of flyers that allow you to easily find the correct positions.

However, during installation, it provides a paper form that must be filled in for each bottle; which shows the data relating to the heights, and adjustments of the various operating heads. In fact, they can be easily found by the operator when they made the format change.

A PLC equip this pre-owned liquid filling machine where the values relating to filing times, rinsing, label peeling, chain pitch, etc. can be stored.